Table of Contents

Advertisement

Quick Links

Original instruction manual

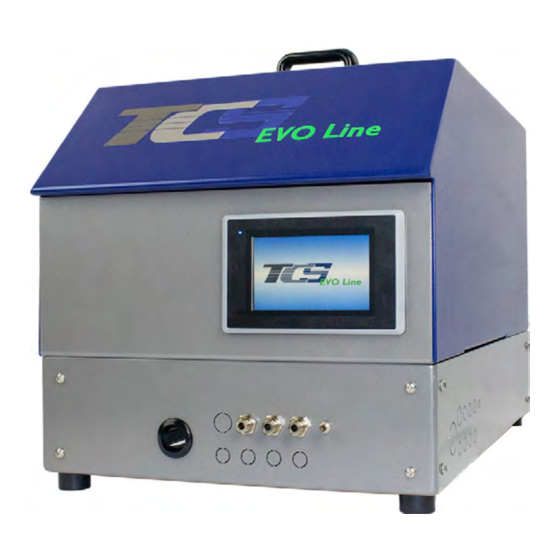

for

TCF

and

TCF

EVOLine

Screw feeders

ATTENTION

To reduce the risk of injury, anyone using, installing, repairing,

servicing, or working near this appliance must read and under-

stand these instructions before performing any of the above

tasks.

DO NOT DISPOSE - HAND OVER TO THE USER

Publication date 16.06.2021

Version 02.05 EN

Valid from serial no. P900129

Advertisement

Table of Contents

Summary of Contents for TCS TCF EVO Line

- Page 1 Original instruction manual EVOLine Screw feeders ATTENTION To reduce the risk of injury, anyone using, installing, repairing, servicing, or working near this appliance must read and under- stand these instructions before performing any of the above tasks. DO NOT DISPOSE - HAND OVER TO THE USER Publication date 16.06.2021 Version 02.05 EN Valid from serial no.

- Page 2 TCF EVO Line and TCF X Line Symbols of the operating instructions Symbols of the operating instructions In these operating instructions, text passages of particular importance are highlighted with symbols described below. Danger! This sign informs you of an immediate danger to the life and health of persons, up to and including life- threatening injuries or death.

- Page 3 TCF EVO Line and TCF X Line Symbols of the operating instructions HMI legend Element Description Means that the state or setting, etc., is active. is ACTIVE or switched on Means that the state or setting etc. is OFF. INACTIVE or switched off Means that the state / status is OK or on.

-

Page 4: Table Of Contents

TCF EVO Line and TCF X Line Table of Contents System overview ..................7 Assemblies ....................7 Structure of the system ................8 Use and mode of operation ..............10 Intended use .................... 10 Declaration of incorporation ............... 11 Mode of operation ..................12 Technical data .................. - Page 5 Maintenance intervals ................113 13.3 Maintenance of the feeder module ............114 13.3.1 Cover of the TCF EVO Line ............... 114 13.3.2 Checking the pneumatic hoses ..............114 13.3.3 Cleaning the sorting bowl in the feeder module .......... 115 14.0 Spare and wear parts ................116 14.1...

- Page 6 TCF EVO Line and TCF X Line Table of Contents 14.9 Pneumatics ................... 125 14.10 Sorting pot .................... 126 14.11 Level control module ................127 14.12 Vacuum module ..................129 14.13 Maintenance unit module ................. 130 14.14 Module delivery unit ................131 15.0 Storage ....................

-

Page 7: System Overview

TCF EVO Line and TCF X Line System overview System overview 1.1 Assemblies TCFEVO Assembly Description Line [1] Housing 2] Base plate with valve battery 3] Sorting pot 4] Separation Abb 1) Assemblies... -

Page 8: Structure Of The System

TCF EVO Line and TCF X Line System overview 1.2 Structure of the system Pos. Element/setting part Function TCF EVO Line Feeding unit Cover Reduction of noise emission Cover flap Opening / closing the filler opening Compressed air connection Connection for system compressed air... - Page 9 TCF EVO Line and TCF X Line System overview Abb 2) Structure of the system...

-

Page 10: Use And Mode Of Operation

For the intended use, observe the technical data (see • chapter3.0, page 13). The TCF EVO Line is to be used in closed rooms where the units • cannot heat up above 45 °C. Unauthorised structural changes, additions or conversions to the •... -

Page 11: Declaration Of Incorporation

TCF EVO Line and TCF X Line Use and mode of operation Declaration of incorporation Declaration of incorporation of the manufacturer (original) For the installation of an incomplete machine in the sense of the EC directives Machinery 2006/42/EC, Annex II, Part 1, Section B... -

Page 12: Mode Of Operation

TCF EVO Line and TCF X Line Use and mode of operation 2.3 How it works TCF EVO Line function modules Conveying and separation function: • Sorting pot (1) • SPiW - Congestion-free buffer section through intelligent Spiral conveyor management. The SPiW can be adjusted by means of settings in the HMI. -

Page 13: Technical Data

TCF EVO Line and TCF X LineTechnical data 3.0 Technical data Technical data of the TCF EVO Line W x D x H 395 x 590 x 420 Room dimensions With open cover H2 [mm] With open cover flap H3... -

Page 14: Safety Instructions And General Information

The operating instructions must always be kept within easy reach at the place of use of the TCF EVO Line. The personnel assigned to work on the TCF EVO Line must have read the operating instructions, especially the chapter "Safety instructions", before starting work. -

Page 15: Data Backups

TCF EVO Line and TCF X LineSafety instructions 4.4 Data backups Please back up all settings of the TCF EVO Line regularly or when and before making changes (parameters, setup settings, etc.) outside the system (e.g. by taking a screenshot of the parameters, backing up the configuration files, see chapter 9.6.2 Backup page). -

Page 16: Set Up And Installation

TCF EVO Line and TCF X LineSetting up and installation Set up and installation 5.1 Setting up the feeder module Place the TCF EVO Line on a horizontal, firm, level surface. 5.2 Connect mains cable and compressed air supply of the feeder module... - Page 17 TCF EVO Line and TCF X LineSetting up and installation Hose lines must be laid or secured in such a way that a hazard is avoided as far as possible. Hose line laid correctly Too narrow a radius A hazard can occur, for example, if the hose or hose assembly is...

-

Page 18: Preparations Before Initial Commissioning

Check the system for transport damage Remove transport lock a. Step 1 This is the delivery status of the TCF EVO Line or TCF X Line. b. Step 2 Take the transport lock in your hand as shown in the illustration. - Page 19 TCF EVO Line and TCF X Line Preparations before initial commissioning c. Step 3 Remove the transport lock as shown in the illustration. Connect the hose assembly a. Connect control line Connect the 5-pin plug to the electrical box (see Fig.5).

- Page 20 TCF EVO Line and TCF X Line Preparations before initial commissioning Query sensors 5 POLIG S1 and S2 for TC-HS , TC-HF and TC- AxFor 4 POLIG TC-HF OPTIONALExtern 3 POLIG OPTIONALHose sensor in front of the mouthpiece Abb 5)

- Page 21 TCF EVO Line and TCF X Line Preparations before initial commissioning Abb 7) Tighten downpipe with Allen key c. If using a pneumatic drive, connect the air supply Connect the air supply as shown in Fig8) [B]. Abb 8) Feed-through feed hose [A] Air supply Pneumatic drive [B ]...

- Page 22 TCF EVO Line and TCF X Line Preparations before initial commissioning When using the TC-Ax module, the communication line must be connected to the SUB D socket on the rear (see Fig.9). If the bus system module is used in addition to the TC-Ax module, the RJ 45 socket must be used for the communication line (see Fig.10).

- Page 23 TCF EVO Line and TCF X Line Preparations before initial commissioning Adjust the mist lubricator, only for units with pneumatic drive. The mist lubricator must be adjusted during commissioning and checked and regulated regularly (weekly) during operation. To do this, proceed as follows: Release the screwdriver for approx.

-

Page 24: Connection Of The Screw Units

(only with pneumatic drive) 6.1 Connection of the screw units Please refer to the respective operating instructions of the systems listed below to connect them to the TCF EVO Line or TCF XLine. TC-HS V2 or TC-HF V2 handheld units •... -

Page 25: Operation

TCF EVO Line and TCF X Line Operation 7.0 Operation Before you start working, read the safety instructions. It's about your health! 7.1 Preparations before daily commissioning 1. Fill the fasteners into the sorting pot (Fig13): Check that the sorting pot does not contain dirt or other foreign bodies. - Page 26 TCF EVO Line and TCF X Line Operation 2. Make sure you use the right type of screws. Avoid foreign bodies or dirt getting into the sorting pot. 3. Check the oil level in the mist lubricator. If there is no oil in the reservoir, it must be topped up.

-

Page 27: Commissioning / Decommissioning

2. If the module maintenance unit is present: Regulate the compressed air to approx. 5 - 6.5 bar flow pressure at the adjusting wheel of the maintenance unit of your supply air for the TCF EVO Line. If the module maintenance unit is not present, please ensure a constant compressed air supply of approx. -

Page 28: Decommissioning

TCF EVO Line and TCF X Line Commissioning / Decommissioning 8.2 Decommissioning 1. Press the red button on the display and pull out the unit plug. The system is disconnected from the voltage. Press 2. Close the shut-off valve of the compressed air supply. -

Page 29: Hmi - Human Machine Interface

TCF EVO Line and TCF X Line Human Machine Interface HMI - Human Machine Interface 9.1 Basic structure The screen is basically divided into 4 areas: Header • System status Date Time Logout button Display symbol that a message is active Main area •... - Page 30 TCF EVO Line and TCF X Line Human Machine Interface Element Description Confirmation of the user password entry Cancel Canceling the user login Change Password Call dialogue for changing the password...

-

Page 31: Password Change

TCF EVO Line and TCF X Line Human Machine Interface 9.2.2 Password change Dialogue for changing the password Element Description Confirmation of the password entry Cancel Cancel Change Password... -

Page 32: Messages

TCF EVO Line and TCF X Line Human Machine Interface 9.3 Messages 9.3.1 Overview messages Notes and error messages are displayed on the message page. The user is informed of an important message by the flashing "message symbol" in the... - Page 33 TCF EVO Line and TCF X Line Human Machine Interface Element Description Button to confirm all message. Necessary when the operator needs to check something. E.g. Message "Please check if screw is jammed. Wait Blade reaches working position. "After the automatic fault clearance was not successful.

-

Page 34: Details Messages

TCF EVO Line and TCF X Line Human Machine Interface 9.3.2 Details messages On the detail page of the messages, all message details are displayed in full. In particular, the complete message texts, which are not displayed in full in the tabular view. -

Page 35: Overview

TCF EVO Line and TCF X Line Human Machine Interface 9.4.1 Overview The main page is displayed as soon as the unit has been started after power has been supplied. Main page without pressure switch module: Main page with pressure switch module:... - Page 36 TCF EVO Line and TCF X Line Human Machine Interface Main page with the communication module active. The screwing results are displayed accordingly. Here is an example of an IO screw connection with a green background. Main page with the communication module active. Here is an example of an...

- Page 37 TCF EVO Line and TCF X Line Human Machine Interface Element Description Level ok Display, with module level monitoring, whether the level of the pot is OK or screws need to be refilled Display, if module Screws IO / NIO "Communication"...

-

Page 38: Manual

TCF EVO Line and TCF X Line Human Machine Interface 9.4.2 Manual On the Manual page, functions can be executed manually by pressing the buttons. For example, to test functions or to control cylinders in case of maintenance or errors. -

Page 39: Portioner - Counting Screws

TCF EVO Line and TCF X Line Human Machine Interface 9.4.3 Portioner - Screw counting If the module "Count screws" is active, the tab "Portioner" is also displayed in the submenu of the main page in order to call up this function. -

Page 40: Standby

TCF EVO Line and TCF X Line Human Machine Interface This function is only available with the "Vacuum" module With display of the vacuum value. This function is only available with module "Vacuum Button to start portioning Start button The portioner can also be started via an external start. -

Page 41: Status Page

TCF EVO Line and TCF X Line Human Machine Interface 9.5 Status page The status page gives information about the current execution times such as singling or adding. Element Description Grant period Display of the current firing time. This function is active with the module "hose sensor system". -

Page 42: Info Page

TCF EVO Line and TCF X Line Human Machine Interface 9.6 Info page The info page offers 3 submenus Help • Backup • Restore • 9.6.1 Help page The help page shows the version of the feeder and the possibility to open the feeder's help page via a QR code. - Page 43 TCF EVO Line and TCF X Line Human Machine Interface Element Description Backup licence Creating a backup of the licence file Backup settings Creating a backup of the settings Backup All Creating a backup of the settings and licence file If the backup cannot be executed, a message is displayed.

-

Page 44: Restore Page

TCF EVO Line and TCF X Line Human Machine Interface 9.6.3 Restore page The restore page allows you to restore the settings and licence data of the feeder from an external USB. If necessary, make a backup of the current status before importing the old data. - Page 45 TCF EVO Line and TCF X Line Human Machine Interface Depending on the selected file, the settings or parameters can then be restored via the "Restore settings" button or the licence data via the "Restore licence" button.

-

Page 46: Settings Page

TCF EVO Line and TCF X Line Human Machine Interface 9.7 Settings page Has 6 submenus: • General User • • Logging Input • Output • Self-Test •... - Page 47 TCF EVO Line and TCF X Line Human Machine Interface The settings page has 5 main menu items, each with these submenu items: • o General o Vibration o Trapdoor o Sorting air • Chopper o Chopper o Shoot •...

-

Page 48: General

TCF EVO Line and TCF X Line Human Machine Interface 9.7.1 General The "General" settings page offers various basic settings for the display. Element Description Switch standby Switching the Feeder to Standby Dialogue for setting the time Set time Dialogue for setting the time zone... - Page 49 TCF EVO Line and TCF X Line Human Machine Interface Adjusting the backlight Background lighting Switching the display language to German German Switching the display language to English English...

-

Page 50: Input

TCF EVO Line and TCF X Line Human Machine Interface 9.7.2 Input The Input page displays the signal inputs of the feeder. Please note that there may be a short delay between signal input and indication on the display, as the display data is not updated as frequently/quickly as the signal run is processed on the control computer. -

Page 51: Output

TCF EVO Line and TCF X Line Human Machine Interface 9.7.3 Output The Output page displays the signal outputs of the feeder. Please note that there may be a short delay between the signal output and the display, as the display data is not updated as frequently/quickly as the signal run is processed at the control computer. -

Page 52: Pot Settings

TCF EVO Line and TCF X Line Human Machine Interface 9.8 Pot settings On the pot settings pages, parameters of the pot can be maintained. Adjustment of this data should only be carried out by trained personnel. Incorrect configurations can lead to malfunctions of the feeder. - Page 53 TCF EVO Line and TCF X Line Human Machine Interface conveyed directly to the chopper again. Funding period until error message Maximum length of time the pot may run without a pause. If this time is exceeded, an error message is displayed.

-

Page 54: Vibration

TCF EVO Line and TCF X Line Human Machine Interface 9.8.2 Vibration The vibration of the pot defines the speed at which the screws are fed. The speed can be entered in the field "Speed [proc.] via the keyboard or set via the slider. -

Page 55: Spiw (Trap Door)

TCF EVO Line and TCF X Line Human Machine Interface 9.8.3 SPiW (trap door) The SPiW (trap door) ensures that not too many screws press on the singling (chopper) and possibly cause jamming. Element Description Down if sensor occupied for [sec.]... -

Page 56: Sorting Air

TCF EVO Line and TCF X Line Human Machine Interface 9.8.4 Sorting air The sorting air ensures that the screws enter the conveyor rail correctly and that there is no canting of the screws Element Description Sorting air on[sec.] Specifies the time for which the sorting air is to be switched on, for pulsating sorting air. -

Page 57: Settings Separation (Chopper)

TCF EVO Line and TCF X Line Human Machine Interface 9.9 Settings Separation (chopper) Adjustment of this data should only be carried out by trained personnel. Incorrect configurations can lead to malfunctions of the feeder. Before making any changes, it is always advisable to make a backup of the current settings. - Page 58 TCF EVO Line and TCF X Line Human Machine Interface All parameters (not only those of the current display) can be read in again by pressing the "Read" button. If changes were made by mistake and not yet saved, the saved values can be read in again.

-

Page 59: Shooting

TCF EVO Line and TCF X Line Human Machine Interface 9.9.2 Shoot The delivery configures the duration of the air blast with which the screw is conveyed through the hose to the mouthpiece or end of the hose. Element Description... - Page 60 TCF EVO Line and TCF X Line Human Machine Interface All parameters (not only those of the current display) can be read in again by pressing the "Read" button. If changes were made by mistake and not yet saved, the saved values can be read in again.

-

Page 61: Settings Licences

TCF EVO Line and TCF X Line Human Machine Interface 9.10 Settings Licences Various licences can be activated for different functions of the feeder in order to activate the function. Licence codes can be managed on the administration page of the licences. - Page 62 TCF EVO Line and TCF X Line Human Machine Interface The administrator has the option of activating a module with a button or setting it to inactive. After activation, the feeder checks whether the licence is correct. If the check of the licence code is successful, this is indicated...

- Page 63 TCF EVO Line and TCF X Line Human Machine Interface All licence data (not only that of the current display) can be re-read by pressing the "Read" button. If changes were made by mistake and not yet saved, the saved values can be read in again.

-

Page 64: Licence Data

9.10.2 Licence data Licences can be added at any time. The licence file can be requested from TCS. To create the licence file, the serial number of the unit from the type plate is required (see Fig.2) and also the software serial number of the unit. - Page 65 TCF EVO Line and TCF X Line Human Machine Interface For the activation of modules, you will receive a licence file that you can import into the feeder.

-

Page 66: Loading A Licence File

TCF EVO Line and TCF X Line Human Machine Interface 9.10.3 Loading a licence file New licences can be requested at any time or existing licence files can be read in again. Here is the step by step procedure: 1. Connect the USB stick (preferably empty and checked by a virus scanner) to a PC and copy the licence file (name freely selectable. - Page 67 TCF EVO Line and TCF X Line Human Machine Interface Change display to Settings ( administrator required)-> Main menu "Licences Start importing the new licence file by pressing the Import button If the USB stick is not recognised, an error message is displayed.

- Page 68 TCF EVO Line and TCF X Line Human Machine Interface If the USB is recognised, a selection dialogue is displayed. The file to be read in must be selected here so that the name appears in the upper field. Press the "Restore licence" button to import the licence data. If licence data already exists, a backup of the existing licence file is created on the USB beforehand.

- Page 69 TCF EVO Line and TCF X Line Human Machine Interface Now you can switch back to the licence settings. Settings ( Administrator required)-> Main menu "Licences The licence codes are displayed. By clicking on the on/off button, you can activate or deactivate licences.

- Page 70 TCF EVO Line and TCF X Line Human Machine Interface After checking the licences, the new licence data must still be saved. To do this, the save button must be pressed If the licence data is not saved, the old data can be displayed again by pressing the read button.

-

Page 71: Serial Number

TCF EVO Line and TCF X Line Human Machine Interface 9.10.4 Serial number The serial number of the feeder is displayed on the serial no. page. This is important, among other things, for the request for licences or support requests. -

Page 72: Functions Of The Modules And Settings

TCF EVO Line and TCF X Line Functions of the modules and settings 10.0 Functions of the modules and settings Under the settings of the modules, the setting values associated with the modules are managed. They can always be set, but only if the corresponding modules are enabled and active. -

Page 73: Module Tc-Hs V2

TCF EVO Line and TCF X Line Functions of the modules and settings 10.2 Module TC-HS V2 Control module TC-HS V2 for TCF-EVO Line Software module for functional integration of the standard hand screwdriver. Future settings of the TC-HS screwdriver could be made here. -

Page 74: Module Tc-Hf V2

TCF EVO Line and TCF X Line Functions of the modules and settings 10.3 Module TC-HF V2 Control module TC-HF V2 for TCF-EVO Line Control module for TC-HF V2 screwdriver Function fixed blade or blade completely extended after the reloading process (accessories: magnet bit, vacuum). -

Page 75: Module Tc-Hf V2 Lever Start

TCF EVO Line and TCF X Line Functions of the modules and settings All parameters (not only those of the current display) can be read in again by pressing the "Read" button. If changes were made by mistake and not yet saved, the saved values can be read in again. -

Page 76: Hose Sensor And Separation Sensor Module

TCF EVO Line and TCF X Line Functions of the modules and settings 10.6 Hose sensor and separation sensor module Hose sensor system Sensory-sensed grant control and provisioning control Allowance time display with monitoring via the display (error messages in... -

Page 77: Bus System Module

10.7 Bus system module ModBus TCP only in combination with module TC-Ax Control of the entire TCF EVO Line, as well as extended operability. Maximum convenience during integrationTransmission of error messages as error codesIndustry 4.0 connection of the TCF EVO LineMaximum interlinking possibilityInformation such as cycle time, feed time, etc. -

Page 78: Outputs Feeder Plc

TCF EVO Line and TCF X Line Functions of the modules and settings 10.7.1 Outputs Feeder PLC Coil Size: 20 Designation Address Data Description Start Size SeparateFinished Signal when the separation of a screw has been carried out SeparateRun Signal that a singling... - Page 79 TCF EVO Line and TCF X Line Functions of the modules and settings ModScrewsCntRunning Signal that the screw count is active PrintOk Signal that the pressure of the feeder is OK ErrorFullStateActive Signal that the fill level has fallen below -> Fill...

-

Page 80: Inputs Feeder Plc

TCF EVO Line and TCF X Line Functions of the modules and settings chapter 12.2 Messages 10.7.2 Feeder PLC inputs Coil Size: 15 Designation Address Data Description Start Size SeparateStart Requirement to place a screw in the hose Reaction to a pos. edge of "SeparateStart... - Page 81 TCF EVO Line and TCF X Line Functions of the modules and settings defined repair attempts, the screw is "SeparateNIO" = ON set and as soon as the process is completely finished also "SeparateFinished" = ON "SeparateRunning" = set. ZuschiessenStart...

- Page 82 TCF EVO Line and TCF X Line Functions of the modules and settings tightened even after the defined repair attempts, it is "GrantNIO" = ON set and as soon as the process is completely finished also "AddDone" = ON and "Feeding Runs"...

- Page 83 TCF EVO Line and TCF X Line Functions of the modules and settings Attention: Only from V1.7 onwards, the feeder can be terminated from standby via Modbus. StandbyOff Cancel standby of the feeder. Attention only functional from V1.7 Holding Register...

-

Page 84: Requirement Separate Screw

TCF EVO Line and TCF X Line Functions of the modules and settings 10.7.3 Requirement Separate screw Standard signal sequence to separate a screw via the bus system. PLC Customer Feeder PLC Signal Description Signal Description Check "StandbyActive" Check whether the Q19 = OFF standby is NOT active. - Page 85 TCF EVO Line and TCF X Line Functions of the modules and settings one communication cycle) so that the feeder PLC could detect the signal change. Check "Injection running" During singling, the firing Q06 = OFF should not be running, so check that the signal "firing...

- Page 86 TCF EVO Line and TCF X Line Functions of the modules and settings Request for acknowledgement must be reset. The error numbers are transmitted in the "Error No." field QA05. See also chapter 9 Messages Wait "SeparateFinished" Wait until the singling Sets "SeparateFinished"...

-

Page 87: Inject Bolt Request

TCF EVO Line and TCF X Line Functions of the modules and settings 10.7.4 Injection screw requirement Standard signal sequence to shoot a screw via the bus system. PLC Customer Feeder PLC Signal Description Signal Description Check "StandbyActive" Check whether the standby Q19 = OFF is NOT active. - Page 88 TCF EVO Line and TCF X Line Functions of the modules and settings Q06 = OFF grants are running. Therefore, check that the signal "ZuschiessenLaeuft" is set to "aus" (off). Set "Injection start" I06 = As soon as the predecessor "Injection Runs"...

- Page 89 TCF EVO Line and TCF X Line Functions of the modules and settings 9 Messages Wait for "Add ready" Q05 = Wait until the grant process Sets "InfeedComplete" Q05 As soon as the grant is reported completed. = ON process is completed, the "GrantComplete"...

-

Page 90: Requirement Bolt Count

TCF EVO Line and TCF X Line Functions of the modules and settings 10.7.5 Requirement Bolts count What happens in the Feeder PLC at: Pos. edge I07 "ModScrewCntStart": Separated quantity is set to 0 Quantity to be separated is set to customer PLC value "ModSchraubenCntSollMengeStk"... - Page 91 TCF EVO Line and TCF X Line Functions of the modules and settings Perform screw counting PLC Customer Feeder PLC Signal Description Signal Description Check "StandbyActive" Q19 = Check whether the standby is NOT active. If necessary, request standby off via "StandbyOff_I15"...

- Page 92 TCF EVO Line and TCF X Line Functions of the modules and settings Now the separation of screws is carried out until the requested quantity is reached or another request such as pause or stop stops the process. Wait "ModScrewsCntRunning"...

- Page 93 TCF EVO Line and TCF X Line Functions of the modules and settings Set "ModScrewsCntStop" I09 = Cancel stop signal again...

-

Page 94: Communication Module

TCF EVO Line and TCF X Line Functions of the modules and settings 10.8 Communication module Electric screwdriver communication (I.O./N.I.O.) and screwdriver start for stand-alone systems Screwdriver start via digital output 10.9 Vacuum module Vacuum screw joint for complicated and deep screw joints High-end vacuum generator and sensor technology installed in the TCF-EVO Line. -

Page 95: Module Feed Unit For Tc-Ax

TCF EVO Line and TCF X Line Functions of the modules and settings All parameters (not only those of the current display) can be read in again by pressing the "Read" button. If changes were made by mistake and not yet saved, the saved values can be read in again. -

Page 96: Module Holder For Tc-Hf V2

TX-Ax units. 10.13 Screw Counting / Portioning Module Counting function for screws end hose This module turns TCF EVO Line into a screw portioner. Screws are dispensed piece by piece. Output speed up to 0.5 seconds per screw possible. -

Page 97: Pressure Switch Module

TCF EVO Line and TCF X Line Functions of the modules and settings Element Description Quantity to be portioned by default Target quantity [pcs.] when a portioning sequence is restarted. This value can be overwritten on the interface or transmitted via the bus module. -

Page 98: Module External Start

TCF EVO Line and TCF X Line Functions of the modules and settings If this value is not reached, a message is generated and the feeder is switched to standby mode. Standby mode does not take place when the TC-Ax module is active. - Page 99 TCF EVO Line and TCF X Line Functions of the modules and settings Element Description If the level sensor continuously Fault active after [sec] reports that the pot is empty or almost empty for the time defined here, the error message regarding the pot's fill level is output.

-

Page 100: Module Remote Start Tc-Hf V2

TCF EVO Line and TCF X Line Functions of the modules and settings 10.17 Module Remote Start TC-HF V2 Remote start for TC-HF V2 Enables remote start of the TC-HF V2, e.g. for an external start handle. -

Page 101: Connecting A Usb Stick To The Display

TCF EVO Line and TCF X Line Connection of USB stick to the display 11.0 Connecting a USB stick to the display A USB storage device can be connected to the display to back up or import data from the feeder. - Page 102 TCF EVO Line and TCF X Line Connection of USB stick to the display...

-

Page 103: Faults, Messages, Causes And Remedies

Faults, messages, causes and remedies 12.0 Faults, messages, causes and remedies 12.1 Faults on the feeder The following faults can occur on the TCF EVO Line. Most of them are indicated on the display of the unit. Malfunction / Fault... - Page 104 TCF EVO Line and TCF X Line Faults, messages, causes and remedies Malfunction / Fault Cause Remedy further Error indication information Compressed air for Set the air pressure for the supply air shock set Chapter 12.3.1 supply air shock too high Screws are jammed on Remove jammed screws.

-

Page 105: Messages

TCF EVO Line and TCF X Line Faults, messages, causes and remedies 12.2 Messages Message list. Messages with a 1000 number are transmitted with the bus system module in the error number tag. Messages with a smaller number are transmitted via an explicit flag in the bus system module, if necessary. -

Page 106: Settings Tcf Evo Line

TCF EVO Line and TCF X Line Faults, messages, causes and remedies 12.3 Settings TCF EVO Line 12.3.1 Set air volume and duration for the supply air blast The screws separated in the baffle of the sorting bowl are transported to the screwdriver by means of an air blast through the feed hose. -

Page 107: Set Pause Time

TCF EVO Line and TCF X Line Faults, messages, causes and remedies 12.3.2 Set pause time To reduce noise emission, the sorting bowl is at rest during work breaks. When the screwdriver is actuated, the sorting bowl immediately becomes active again. -

Page 108: Remove Jammed Screws From The Outlet Rail

TCF EVO Line and TCF X Line Faults, messages, causes and remedies 12.3.5 Remove jammed screws from the outlet rail 1. Press the red button on the display and pull out the unit plug. The system is disconnected from the voltage. - Page 109 TCF EVO Line and TCF X Line Faults, messages, causes and remedies 5. Put the chicane back on. 6. Reconnect the unit plug to the mains. The system is now connected to the mains, the blue LED on the display lights up. Press the red button on the display.

-

Page 110: Loosening Jammed Screws On The Singling Device

Press 2. Disconnect the compressed air supply from the TCF EVO Line 3. Lift the cover plate of the separator (A in Fig17) and turn the cover plate to the side. (B in Fig17) -

Page 111: Adjusting The Conveying Speed Of The Sorting Bowl

TCF EVO Line and TCF X Line Faults, messages, causes and remedies 4. Remove the jammed screws. 5. Turn the cover plate back over the singling. 6. Reconnect compressed air. 7. Reconnect the unit plug to the mains. The system is now connected to the mains, the blue LED on the display lights up. -

Page 112: Maintenance

13.1 Safety instructions for maintenance, servicing and troubleshooting Carry out the maintenance work prescribed in the operating instructions in due time. This will prolong the life of the TCF EVO Line. Maintenance, inspection and repair work may only be carried out by personnel with the appropriate qualifications. -

Page 113: Maintenance Intervals

TCF EVO Line and TCF X Line Maintenance 13.2 Maintenance intervals Maintenance intervals Maintenance intervals More Assembly Maintenance Information • Visual inspection for Replace immediately if Screwdriver housing external damage cracked. Visual inspection of • the cover for Chapter 13.3.1 external damage •... -

Page 114: Maintenance Of The Feeder Module

TCF EVO Line and TCF X Line Maintenance 13.3 Maintenance of the feeder module 13.3.1 Cover of the TCF EVO Line Visually inspect the cover of the feeder module. An intact, closed bonnet reduces the noise of the sorting bowl and prevents the ingress of foreign bodies or dirt. -

Page 115: Cleaning The Sorting Bowl In The Feeder Module

TCF EVO Line and TCF X Line Maintenance 13.3.3 Cleaning the sorting bowl in the feeder module 1. Press the red button on the display and pull out the unit plug. The system is disconnected from the voltage. Press 2. -

Page 116: Spare And Wear Parts

TCF EVO Line and TCF X Line Spare and wear parts 14.0 Spare and wear parts 14.1 Parts list declaration In principle, Technik Center screwdriving systems products are designed in such a way that spare and wear parts are kept to a minimum. -

Page 117: Parts List Overview - Assemblies

TCF EVO Line and TCF X Line Spare and wear parts 14.5 Parts list overview - assemblies 14.6 Feed module 14.7 Guide rail 14.8 Separation 14.9 Pneumatics 14.10 Sorting pot 14.11 Module level control 14.12 Vacuum module... - Page 118 TCF EVO Line and TCF X Line Spare and wear parts 14.13 Maintenance unit 14.14 Module delivery unit module...

-

Page 119: Feeding Module

TCF EVO Line and TCF X Line Spare and wear parts 14.6 Feeding module... -

Page 120: Guide Rail

TCF EVO Line and TCF X Line Spare and wear parts 14.7 Guide rail... - Page 121 TCF EVO Line and TCF X Line Spare and wear parts Component Pos. Designation Article number Guide rail below outside 1000005076 Guide rail bottom inside 1000005077 Guide rail support outside 1000005078 Guide rail support inside 1000005079 Guide rail cover 1000005080...

-

Page 122: Separation (Chopper)

TCF EVO Line and TCF X Line Spare and wear parts 14.8 Separation (chopper) - Page 123 TCF EVO Line and TCF X Line Spare and wear parts Component Pos. Designation Article number Separating block 1000005264 Guide plate 1000005324 Separating plate 1000005325 Locking piece 1000002491 Downpipe plate 1000005053 Intermediate plate 1000002489 Cover 1000005113 Hexagon nut low form M5...

- Page 124 TCF EVO Line and TCF X Line Spare and wear parts Throttle valve 3700040047 Cylinder plate 1000005057 Spacer 1000005058 Coupling piece 1000005059 Parallel pin 4x10 5094504010 Separation cover plate 1 1000005060 Separation cover plate2 1000005061 Fitting screw 2000002142 Parallel pin 5x20...

-

Page 125: Pneumatics

TCF EVO Line and TCF X Line Spare and wear parts 14.9 Pneumatics... -

Page 126: Sorting Pot

TCF EVO Line and TCF X Line Spare and wear parts 14.10 Sorting pot... -

Page 127: Level Control Module

TCF EVO Line and TCF X Line Spare and wear parts 14.11 Filling level control module Component Pos. Designation Article number Sensor 2000001697 Shaft vertical 1000005232 Shaft horizontal 1000005233 Integrated in Control line the wiring harness Stand 1000005234 Mounting bracket... - Page 128 TCF EVO Line and TCF X Line Spare and wear parts Bearing seat 1000005236 Clamping for sensor 1000005237 Swivel rod 1000005238 Ball bearing 2000002120 Clamping ring 1000005239 Screw M5x16 Screw M5x16 Screw M5x8 Screw M5x8 Screw M5x12 Screw M5x12 Screw M3x8...

-

Page 129: Vacuum Module

TCF EVO Line and TCF X Line Spare and wear parts 14.12 Vacuum module Component Pos. Designation Article number Filter 2000002115 Vacuum generator 2000002105 Connection piece 2000002113 Connection piece 2000002114 Angle plate 1000005272 Sensor 2000002106 Screw M4x8 Screw M4x8 Screw M5x30... -

Page 130: Maintenance Unit Module

TCF EVO Line and TCF X Line Spare and wear parts 14.13 Maintenance unit module Component Pos. Designation Article number Retaining plate 1000005258 Connection 2000002102 Maintenance unit 2000002103 Screw M6x12 Screw M6x12... -

Page 131: Module Delivery Unit

TCF EVO Line and TCF X Line Spare and wear parts 14.14 Module delivery unit... -

Page 132: Storage

TCF EVO Line and TCF X Line Spare and wear parts 15.0 Storage The TCF EVO Line should be stored in plastic packaging. Observe the following storage conditions: -dry -under roof -Storage temperature approx. 5 °C - +50 °C 16.0 Disposal... - Page 133 Original instruction manual...

Need help?

Do you have a question about the TCF EVO Line and is the answer not in the manual?

Questions and answers