Advertisement

Quick Links

IMPORTANT: Read and follow all instruc-

tions and SAFETY PRECAUTIONS before

using this equipment. Retain for future

reference.

DESCRIPTION

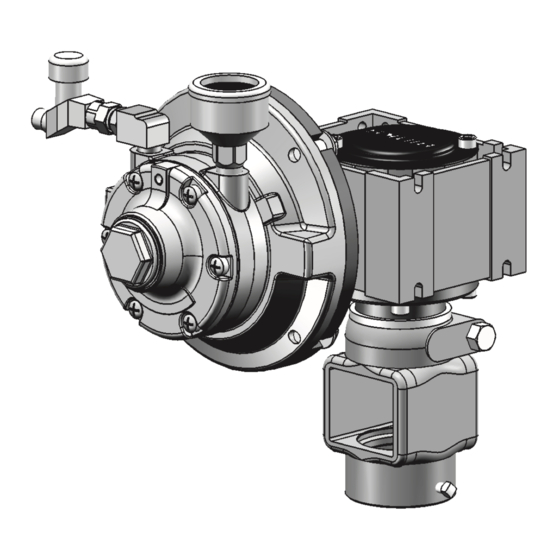

The QS-5001 air motor covered in this

service bulletin is designed to drive paint

agitators when connected to a source of

clean, dry, air pressure. Maximum air

input 100 PSI.

QS-5001 standard duty air motor drive,

1/4 h.p., 15:1 ratio, 20 to120 RPM for pres-

sure tank agitator. Includes air adjusting

valve with necessary hose and fittings for

hookup to tank regulator. Overall height

8", width 7-3/4".

High pressure can cause serious

injury. Pressure is maintained in

a pressure tank after the system

has been shut down. Before

attempting removal of fill plug

or cover, relieve tank pressure.

QS-5001 AIR MOTOR DRIVE

Pressure Relief Procedure

1.

Turn off the main air supply to the

tank.

2.

Close air inlet valve located on tank

air manifold.

3.

bleed off air in the tank by turning

the relief valve handle counter-

clockwise. Wait until all the air has

escaped through the valve before

removing the pressure tank cover

or fill plug.

4.

Leave the air relief valve open until

you have reinstalled the cover or fill

plug.

INSTALLATION

QS-5001 Installation onto Pressure Tank

with Agitator. (Refer to Figure 1.)

1. Place support (12) over agitator bear-

ing housing in tank lid and tighten in

place. Tighten setscrew (14) in either

screw hole.

2. Set air motor drive on support (12)

so that gear box shaft (35) engages

agitator shaft. Tighten cap screw (13).

3. For single regulation proceed as fol-

lows:

a. Remove air inlet valve from regula-

tor on tank and install service tee (1)

in regulator.

b. Reinstall air inlet valve in service

tee (1).

c. Install nipple (2) in service tee (1).

Install hose assembly (3) between

nipple and air adjusting valve (4) on

air motor.

4. For double regulation proceed as fol-

lows:

a. Remove plug from main line

port of lower regulator and install

nipple(2).

b. Install hose assembly (3) between

nipple (2) and air adjusting valve (4)

on air motor.

SERVICE bULLETIN

SB-19-085-P

Replaces Sb-19-085-N

OPERATION

Open valve to main air line; then slowly

open air adjusting valve until agitator

turns. To extend air motor life, adjust air

pressure setting to run motor at about one

revolution per second. The agitator should

be run continuously while using the tank.

PREVENTIVE MAINTENANCE

Air Motor Lubrication

Failure to properly lubricate

the air motor will result in

premature motor failure and

will void warranty.

Lubricate air motor daily by

adding 4 or 5 drops of SAE 10

weight oil into air inlet fitting.

Periodically - Remove air adjusting valve

and air strainer and flush motor with a

clean suitable solvent. Remove trapped

particles from screen in air inlet and clean

air strainer felt.

Air Motor Gear Box Lubrication

Every 2 Days - Remove oil fill plug and

check oil level. If oil level is low, add

140-weight SAE Gear Oil or a high quality

worm gear lubricant. Replace pipe plug

and tighten to 20 foot-pounds (27 N

of torque.

Note

Gear box oil is most easily

drained just after motor opera-

tion, while oil is still warm.

Approx. 1/8" Gap

(top of oil level to

bottom of fill hole)

Note

Do not overfill. Overfilling may

cause oil to leak out of vent cap

on top of gear box.

m)

.

Advertisement

Summary of Contents for DeVilbiss QS-5001

- Page 1 The QS-5001 air motor covered in this 2. Set air motor drive on support (12) service bulletin is designed to drive paint Air Motor Gear Box Lubrication...

-

Page 2: Safety Precautions

PAGE 2 Sb-19-085-P SAFETY PRECAUTIONS This manual contains important information that all users should know and understand before using the equipment. This informa- tion relates to USER SAFETY and PREVENTING EQUIPMENT PRObLEMS. To help you recognize this information, we use the following terms to draw your attention to certain equipment labels and portions of this Service bulletin. -

Page 3: Replacement Of Parts

Sb-19-085-P PAGE 3 After first 250 hours of operation, remove Gear Box (Refer to Figure 3.) gear box and drain gear oil. Refill gear box with 140-weight SAE Gear Oil or a Remove oil fill plug (37) or cover plate high quality worm gear lubricant. - Page 4 PAGE 4 Sb-19-085-P FIGURE 1 GEAR DRIVE AIR MOTOR QS-5001 (STANDARD DUTY) See Figure 3 for Gear box Assembly Fill Figure 2 for Air Motor. Replacement Ind. Parts Part No. Description Req'd. Service Tee 1/4" Galvanized Purchase Locally H-2008 Nipple 1/4" NPS(M) x 1/4"...

- Page 5 Sb-19-085-P PAGE 5 FIGURE 2 QS-4016 AIR MOTOR Replacement Ind. Parts Part No. Description Req'd. QS-336 Oil Seal QS-197 bearing Purchase Locally Machine Screw 1/4-28 x 1/2 QS-334 End Plate QS-189-1-K10 Dowel Pin (Kit of 10) • PT-59-K10 End Plate Gasket Kit (Kit of 10) •...

- Page 6 PAGE 6 Sb-19-085-P FIGURE 3 GEAR BOX ASSEMBLY When Replacing Ref. No. 31, Torque to 15 in-lbs. min. When Replacing Ref. No. 40, Torque to 60 in-lbs. min. Apply SS-9868 Sealant to Threads as Needed. Motor Shaft Replacement Ind. Parts Part No.

- Page 7 Sb-19-085-P PAGE 7 AIR MOTOR DRIVE SERVICE CHECKS CONDITION CAUSE CORRECTION A. Air motor sluggish or inefficient. 1. Air motor needs cleaning. 1. Disassemble and clean per parts replacement instruc-tions. 2. Motor vanes need replacing or 2. Disassemble, clean motor per parts contaminants present in motor replacement instructions.

-

Page 8: Warranty

Repair Kit PT-77-K10 End Plate PT-59-K10 End Plate Gasket Kit Directly. O-Ring WARRANTY This product is covered by DeVilbiss’ 1 Year Limited Warranty. DeVilbiss Sales and Service: www.devilbiss.com U.S.A./Canada Customer Service Toll Free Customer Service and Technical Support 195 Internationale Blvd.

Need help?

Do you have a question about the QS-5001 and is the answer not in the manual?

Questions and answers