Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Meech A70025

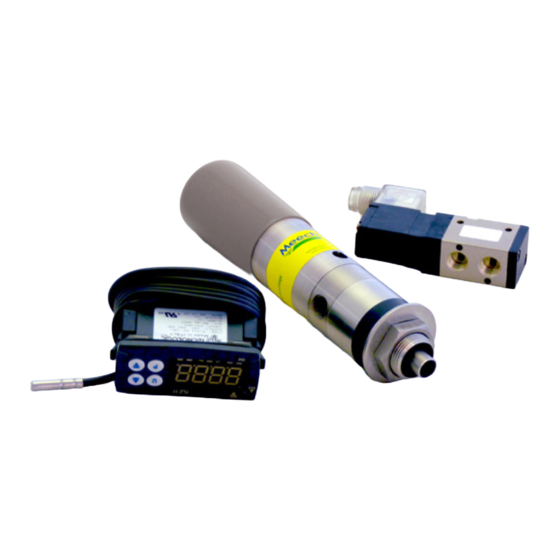

- Page 1 Operating Manual Cabinet Cooler & Cabinet Cooler System...

-

Page 3: Table Of Contents

10. Troubleshooting Products shown in this document may be covered by one or more patents, patents applied for and/or registered designs and/or trade marks. For further information please refer to our Head Office or visit www.meech.com. © Meech Static Eliminators Ltd. -

Page 5: Introduction

1. Introduction The Meech Air Technology Stainless Steel Cabinet Cooler uses compressed air to provide a cold air source which stops industrial cabinet/panels or enclosures overheating and prevents ingress of contamination such as dust or moisture. The Cabinet Cooler Unit (excluding Solenoid Valve and Thermostat) is intrinsically safe, and requires virtually no maintenance. -

Page 6: Safety And Inspection

2. Safety and Inspection Meech Cabinet Coolers are packed carefully at our factory. Nevertheless, we recommend careful examination of the carton and contents for any damage. To protect yourself and others when using compressed air, you should be aware of the following general safety guidelines: Warning –... -

Page 7: Maintenance

3. Maintenance The Meech Cabinet Cooler has no moving parts. Clean compressed air moving through the Cabinet Cooler will not cause wear on any of the components. Occasionally, dirt, water or oil may enter the cooler from the compressed air supply. -

Page 9: Compressed Air Supply

4. Compressed Air Supply It is recommended to use a 5-micron (or smaller) filter to remove water and dirt from the compressed air supply. A 5-micron filter will remove 99% of foreign material from the air supply; the use of an oil filter with an effective filtration of 0.01 ppm will remove the oil droplets for an even cleaner compressed air supply. -

Page 10: Compressed Air Line Sizes

5. Compressed Air Lines Sizes Figuring the correct pipe size for your compressed air system is an important task. Pipe that is sized too small can create big pressure losses and reduce operating efficiency. Many people who plan the piping never consider the fittings or the future. FITTINGS: Every pipe fitting creates a certain amount of increased frictional air loss that is equal to a specified length of pipe. - Page 11 LENGTHS OF PIPE needed for each PIPE FITTING. Write these lengths on your piping schematic at each fitting. TOTAL all the EQUIVELENT LENGTHS OF PIPE needed for each PIPE FITTING and add to your total of straight length of pipe. This will give you a new and more accurate total pipe length needed.

- Page 12 How to determine what size of PIPE you need for compressed air lines: TABLE 1: EQUIVALENT LENGTH OF PIPE LINES IN FEET Don’t forget to include *PIPE FITTINGS in your final calculations Your Air Compressor’s feet feet feet 100 feet 150 feet 200 feet 250 feet...

-

Page 13: Installation

6. Installation The drawing below shows the recommended way to fit a Meech Cabinet Cooler and Cabinet Cooler System (including digital thermostat and solenoid valve). Solenoid Valve 240v/110v/24v Cabinet Cooler Air Inlet Filter Cabinet Wall Digital Thermostat Ducting Thermocouple To fit the Cabinet Cooler follow the steps below: A. - Page 14 Please remember to re-fit the o-ring and screw bulk head fitting until tight. Four generators are provided with the Meech Cabinet Cooler. Information on all generators and sizing can be found in section 7.

- Page 15 D. Fit Cabinet Cooler in place From outside the enclosure, place the cold end of the Cabinet Cooler into the drilled hole. E. Re-fit bulk head nut and washer Once this is done tighten bulk head nut & washer until the Cabinet Cooler is secure. F.

-

Page 16: Operation

7. Operation 1. Cabinet Cooler The Cabinet Cooler is factory set to deliver the most efficient cooling needed to maintain a desired temperature inside an enclosure. At 80psi (5.5 Bar), 10cfm (70% of 15 cfm, red generator) of cold air will exit from the Cabinet Cooler providing 293 Watts (1,000 Btu) of Cooling. - Page 17 Blue 25cfm (708 l/min) – Cooling capacity of 499W (1,700 Btu/hr) Brown 35cfm (991 l/min) – Cooling capacity of 703W (2,400 Btu/hr) A single Meech Cabinet Cooler is capable of cooling up to 703 Watts (2,400 Btu/hr). Optimising the cooling capacity is still a vitally important factor, choosing the correct generator will not only reduce running costs but also extend the life of the compressor.

- Page 18 3. Humidity If a cabinet cooler is run constantly relative humidity inside the cabinet stabilises at approximately 45%. To prevent condensation forming on the cold air pipe close off any vents or fan outlets on the outside wall of the enclosure. This reduces the ambient air from circulating within the cabinet/panel and reduces the chance of condensation.

-

Page 19: Solenoid Valve And Thermostat (Cabinet Cooler System Only)

22°C. At this point the Cabinet Cooler is deactivated ready for the process to start again. Adjustment of Meech Factory settings The thermostat is password protected to stop adjustment of the parameters. The following 3 steps explain how to unlock the thermostat for parameter adjustment. - Page 20 Point is the temperature that once activated the system will cool the cabinet/panel to (factory set to 22°C). Once you have entered your Set Point press the ‘P’ button once. This will activate the new setting and return you to the main toggle menu. Using the 2 arrow buttons toggle through the parameters until you reach ‘HSEt’.

-

Page 21: Approvals

9. Approvals The Meech Cabinet Cooler is IP56 (Nema 4/12) The Cabinet Cooler unit is issued in accordance with Directive 94/9/EC (“ATEX”) – Equipment and protective Systems Intended for use in Potentially Explosive Atmospheres A Declaration of manufacture is available on request. -

Page 22: Troubleshooting

10. Troubleshooting Air flow Problems with compressed air flow can be caused by: Air pressure too low – increase air pressure at the relevant regulator Undersized compressed air lines – replace pipes with correct sizes, see section 5 Blocked compressed air line – remove blockage Insufficient compressor size –... - Page 24 #25 Xiangfeng Road India 201103 Shanghai Tel: +36 27535075 China Fax: +36 27535076 Tel: 020-26069641/ 26069642, email: ce@meech.com Fax: 020-26069644 Tel: +86 400 820 0102 e-mail: india@meech.com Fax: +86 21 6405 7736 email: china@meech.com © Meech Static Eliminators Ltd 2014 www.meech.com...

Need help?

Do you have a question about the A70025 and is the answer not in the manual?

Questions and answers