Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Fast Aqua M300 D

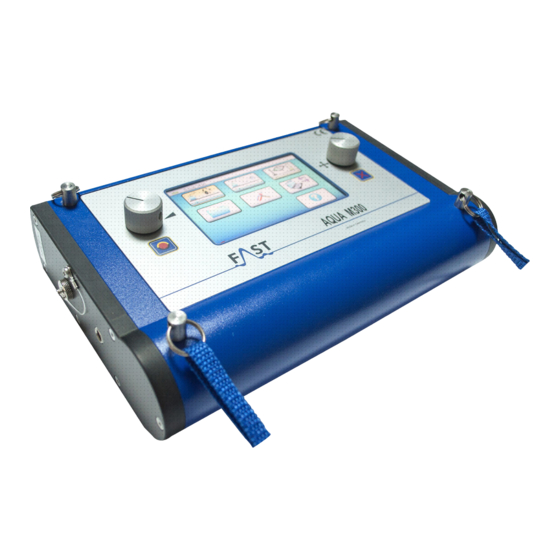

- Page 1 Aqua M300 D Operating Instructions Manual Aqua M300D page 1...

-

Page 2: Table Of Contents

Contents: 1. Safety Instructions Measuring Procedure 9. Trace Gas Detection 2. Intended Use 9.1 Putting the Device into Operation 3. Scope of Delivery and Accessories 9.2 Display 4. Control Elements 9.3 Normal Measuring with Acoustic Feedback 5. Powering up and Operating the Device 6 9.4 Defining Alarm Thresholds 9.5 Measuring with Zero Calibration Headphone Jack and Sensor Port... -

Page 3: Safety Instructions

The measuring device was designed and manufactured in line with the latest technological advancements and complies with the requirements as laid down in existing European and national guidelines. Conformity has been proved, and the relevant declarations and documents are in the manufacturer’s possession. As the user, you must read and adhere to the following safety instructions in order to ensure that this condition is maintained and that no danger results from the use of this device. -

Page 4: Scope Of Delivery And Accessories

3. Scope of Delivery and Accessories 12 tripod for microphones (4 + 5), small 1 Aqua M 300D central unit 13 extensions with tip M 6 2 sound-blocking headphones 14 magnet for microphones (4 + 5) 3 wind-protected ground microphone 15 extensions with tip M10 4 universal microphone 16 adapter M6 / M10... -

Page 5: Control Elements

4. Control Elements 1 Left-hand volume dial 4 Cancel key This dial has two functions: you can either press 2 A or turn 2B the dual-function dial. Turn the dial to adjust Press briefly to access the superior menu. Press long the volume of your headphones while measuring is to clear the current measurement series. -

Page 6: Powering Up And Operating The Device

5. Powering up and Operating the Device 5.1 Headphone jack and sensor port First place the batteries into the battery compartment of the Aqua M300 and connect all the components you require to perform the specific measurement operation. Headphones: Connect the headphones to the headphone jack of the Aqua M300 (see chapter 4, legend item 7) . Use the original Aqua M300 headphones only. -

Page 7: Connecting The Hydrogen Sensor

5.1.2. Connecting the Hydrogen Sensor The H2 hydrogen sensors can be connected to the Aqua M300 to carry out non-destructive leak detections in systems that have previously been flooded with trace gas. Connect the sensor to the hydrogen sensor port (see chapter 4, legend item 10) of the Aqua M300. -

Page 8: Help

6.3 Help The Aqua M300 is equipped with an integrated help function which can be accessed from either side. Navigate to the menu item Help in the upper menu bar as described in Chapter 6.1 to get to the Help main page. Scroll to the Help topic which you would like to find out about and confirm your selection by pressing the dial on the right to get to the help text you require. -

Page 9: Settings

6.4 Settings You can reach the menu Settings via the Settings symbol in the main menu. Navigate to the settings you wish to select and carry out your selection in order to perform the following configurations: 6.4.1. Time and Date Use the dial on the right to navigate to the selection field of your choice. -

Page 10: Frequency Range

6.4.5. Frequency Range Each of the measuring modes that can be used during acoustic leak detection has both a selection of pre-defined filters and a selection of user-defined filters which can be configured in the setting window Frequency Range. The settings of the high-pass filter (HP), the low-pass filter (LP), and the maximum breadth of the colour spectrum can all be changed. -

Page 11: Acoustic Leakage Detection

7. Acoustic Leakage Detection In order to be able to carry out acoustic leak detection with the AquaM300, first activate the symbol for your acoustic leak detection measuring operation in the main menu and confirm your selection. The first selected mode is the pre-defined smart mode. There are two other modes available in addition to the smart mode: the F&V mode (frequency and volume) as well as the V mode (sound level). -

Page 12: Selecting The Filter Presetting

7.1.2 Selecting the Filter Presetting You can select one of three predefined filters when carrying out acoustic leak detection. Each of the filters can be changed individually during measuring. To select one of the predefined filter settings, navigate to the filter mode symbol (1) on the display, activate the symbol and confirm your selection. -

Page 13: Volume Setting

7.1.3 Volume Setting You can adjust the volume of the headphones subject to the predefined hearing protection to suit your requirements (see chapter 6.4.6.). The volume you have selected will either be displayed numerically in the symbol for the volume of the headphones (1) and, in addition, as a bar diagram. -

Page 14: Mode Selection

7.2.2. Mode Selection The measuring mode symbol (1) on the display shows which mode has been set. To call the requested measuring mode, press the dial (3) (2) Smart Mode (3) Volume Mode (4) Searching for a Pipe (see chapter 10) 7.2.2.1 Measuring Procedure Smart Mode Press the record button or the press button on the handle at the universal microphone (5) to start measuring. -

Page 15: Measuring Procedure Volume Mode

The right-hand, thin bar (4) represents the smart indicator. The smart indicator is based on a complex set of calculations and analysis methods (see chapter 7.2.1). The higher the smart indicator value, the more reliable the information on the leak. The smart indicator bar also displays the colour of the frequency which was used for the calculation that is required to provide an indication on the whereabouts of the leak. -

Page 16: Clearing Current Measurement

7.3. Clearing the Current Measurement Series As many as seven individual measurements can be carried out with the Aqua M300 and used as a measurement series which can then be displayed. This series remains in the memory – even when the device is powered off – unless certain parameters are changed. - Page 17 When working in the field, the setting for the low-pass filter is ideal when all the high-frequency sounds lie within the selected range and the high-pass filter is set so that the bottom left-hand sector of the selection box is on the right-hand sloping flank of the biggest part of the spectrum.

-

Page 18: Acoustic Long-Term Measuring

8. Acoustic Long-Term Measuring You can carry out acoustic long-term measuring with the Aqua M300 in order to determine over a longer period whether a certain sound can be attributed to either a leak or to environmental sources such as pumps, flow-related noises in canals, etc.. -

Page 19: Measuring Procedure

Setting the volume (4): To select the volume for long-term measuring, perform the same steps as described for current measurements in chapter 7.1.3. Furthermore, the volume function for long-term measuring can be deactivated at any time by pressing the dial on the left (1) once. -

Page 20: Putting The Device Into Operation

9.1 Putting the Device into Operation As soon as you change to trace gas detection on the display when the hydrogen sensor is connected, the device recognises the sensor and warms it up to operating temperature. This warm-up phase takes approximately 3 minutes and is displayed as a green progress bar (1) below the numerical display. -

Page 21: Normal Measuring With Acoustic Feedback

The functions and setting options of these parameters will be explained in detail in the following chapters. 9.3 Normal Measuring with Acoustic Feedback NOTE: Information on the displayed values: The Aqua M300 hydrogen sensor is capable of detecting highly resolved hydrogen concentrations from 10 to 20.000 ppm. -

Page 22: Defining Alarm Thresholds

The sound is emitted in the same volume as a continuous tone via the headphones. The frequency depends on the measuring value. The frequency increases when the measuring values increase (the tone becomes higher) and decreases when the measuring values decrease. 9.4 Defining Alarm Thresholds In order to allow you to identify certain hydrogen concentrations more easily, the Aqua M300 is equipped with a permanent alarm function with alarms thresholds that can be configured individually. -

Page 23: Clearing The Measurement Series

The digit display now shows two values: the relative measured value (relative to the defined reference value, 000 display at the point of zero calibration) as large digits in the middle of the digit display and the measured absolute measurement value beneath as reference value when zero calibration was carried. The displayed values change as follows when the hydrogen concentration increases: the relative measured value shows the increasing values in relation to the defined reference value. -

Page 24: Searching For A Pipe

To select the “Searching for a Pipe” measuring mode, perform the same steps as described in chapter 7.2. Searching for a pipe can be carried out only in combination with the optional FAST-PWG (pulse wave generator) (see Accessories (19)). The PWG is mounted to the pipe and in direct contact with the pressurized liquid (hydrants, boreholes, ventilations, etc.). -

Page 25: Procedure

10.2 Procedure Press the left-hand key (2) or, if applicable, the button on the handle, to start the measurement. As soon as the key or the button has been released, the measurement will be stopped and saved. The frequency and the sensitivity have to be set so that you can clearly see the measuring impulse. Cross the pipe in a diagonal way while performing the measurement. -

Page 26: Transferring Measurement Data To A Pc

You will need the PC connecting cable included in the scope of delivery and a software tool which you can download at www.fastgmbh.de or request from FAST and load to your PC. NOTE: The software tool which you may select to download is absolutely free of charge and is not part of the standard scope of delivery. - Page 27 Please ensure that your PC is connected to the Aqua M300 with the PC connecting cable, then navigate to the Data Transfer display symbol (1), confirm your selection, and follow the instructions as shown on your PC. Manual Aqua M300D page 27...

-

Page 28: Troubleshooting

13. Troubleshooting Acoustic Leak Detection – List of possible errors or faults: Error/Fault Description Possible Cause Recommended Action No sound in the 1. The sound receiver or the Check the connections between the connected sound receiver and the headphones headphones are not connected headphones and the Aqua M300. -

Page 29: Changing The Battery, Cleaning, And

14. Changing the battery, Cleaning, and Maintenance Changing the battery There is a battery symbol above the menu bar on the left-hand side of the display that shows you how much power the batteries of the Aqua M300 leak detection device have left. The more green segments there are, the higher the battery capacity. -

Page 30: Technical Specifications

15 Technical Data Technical Data Aqua M300 Operation modes Acoustic leak detection (volume, smart, long-term measuring), trace gas detection, and search for pipes Measuring modes for minimum levels, averaged levels, pulse wave measurements Measuring functions and device Logging function, memory preference for manual filter settings, sound level functions overmodulation protection, trace gas detection with concentration-dependent signal (optic and acoustic) -

Page 31: Information For Use In The Field

16. Information for Use in the Field 16.1. Acoustic Leak Detection 16.1.1.2. Structure-borne Sound Structure-borne sound oscillations occur when water escapes from a 16.1.1. How Sound is Created leak with high pressure and at a correspondingly high speed which causes the pipe in question to oscillate. When there is a leak in a high-pressure pipe system, water that leaks out generates sound that is caused by the friction that occurs when the The sound that is generated at the point where the water is escaping... -

Page 32: Pinpointing The Leak By Using

16.1.2.2 Pinpointing the Leak by Using a Ground Microphone 16.2.3 Determining Correct Quantities Using Experience Gained in the Field If you have managed to detect a defective pipe section using the stick microphone, you can use the ground microphone to pinpoint the leak. Wif a pressure test with water has already been carried out on the pipe, Always make sure that the distance between any two points that you then the pressure at which water no longer escapes through the leak ca...

Need help?

Do you have a question about the Aqua M300 D and is the answer not in the manual?

Questions and answers