Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Carver 4350

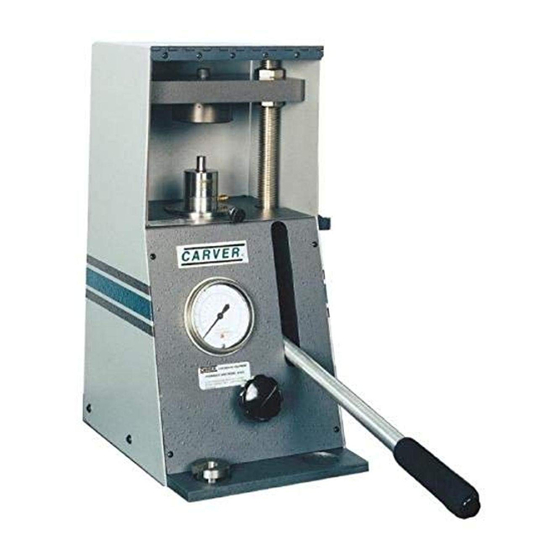

- Page 1 ® CARVER OPERATION, INSTALLATION AND MAINTENANCE MANUAL 4350 MANUAL PELLET PRESS IMPORTANT: PLEASE READ CAREFULLY BEFORE INSTALLING OR OPERATING THIS EQUIPMENT CARVER, INC. 1569 Morris Street, P.O. Box 544 Wabash, IN 46992-0544 PH: 260-563-7577 FAX: 260-563-7625...

- Page 2 29.92" Hg (10,331 Kg/m2) at sea level and using 60 Hz electrical current. All of these factors are important considerations when selecting a hydraulic press. CARVER, INC. can advise you on proper selection and sizing of systems for the operating environment at your location.

-

Page 3: Table Of Contents

OPERATING THE HYDRAULIC PRESS.................. 3-1 DAYLIGHT ADJUSTMENT....................... 3-1 SECTION FOUR MAINTENANCE......................4-1 TROUBLESHOOTING........................ 4-1 HYDRAULIC UNIT - AIR BLEED PROCEDURE..............4-1 RECOMMENDED HYDRAULIC OILS FOR CARVER PRESSES.......... 4-1 SECTION FIVE ACCESSORY EQUIPMENT..................5-1 SECTION SIX CARVER, INC. SERVICES ..................6-1 TECHNICAL ASSISTANCE....................... 6-1 RETURNED MATERIAL POLICY .................... -

Page 4: Section One

INTRODUCTION INTRODUCTION We are pleased to supply CARVER Laboratory Equipment for your facility. CARVER presses are used in many applications including research and development, specialized or low volume development situations, and quality testing. Thousands of presses are in use all over the world for numerous applications in the chemical, physical, biological, and mechanical fields wherever pressing is required. - Page 5 The principle factors that can result in injury are: Failure to center the work over the ram in the platen area, resulting in eccentric loading, tilting, and possible movement of the work piece, which can then become a projectile; Failure to level the top head of the press after it has been repositioned, which can produce the same results as in Number One, above;...

-

Page 6: Section Two

IMPORTANT: DO NOT operate the hydraulic unit with the solid shipping plug in the oil fill hole or damage to the hydraulic unit may occur. The CARVER Manual Pellet Press was carefully designed with a low center of gravity and an extended base to remain stable under normal operating conditions. -

Page 7: Filling The Oil Reservoir

FILLING THE OIL RESERVOIR The hydraulic unit is filled with oil at CARVER, INC. and should not require additional oil. In the event there is some oil loss, lower the platen, remove the sintered breather plug, and fill with oil up to the level of the filler hole. Only special CARVER # 2170 Hydraulic Fluid, or a brand name filtered HYDRAULIC JACK OIL, should be used. -

Page 8: Section Three

Place the CARVER 3619 Pellet Die in the recessed area on the 4” dia. Platen (be sure the die is seated in the bottom of the recess). This will prevent tilting of the platen and possible ejection of the work piece under pressure. - Page 9 Threaded columns allow for daylight adjustment between the moving platen and top bolster. o raise the top bolster Remove back panel by removing the (6) button head cap screws. Remove the eyebolt from the top bolster. Remove safety shield top/side/door assembly by removing (4) button head cap screws from the bottom of the shield and lifting the assembly off of the press.

- Page 10 Tighten the upper column nuts finger tight a gainst the top surface of the top bolster. Follow steps 9 thru 14 as described above. ARNING: After adjusting the daylight, be sure the top bolster is parallel to the top surface of the base bolster before applying pressure.

-

Page 11: Maintenance

FOUR MAINTENANC Each CARVER Laboratory Press is thoroughly tested to provide trouble-free performance. Manufacturing and assembly processes are closely controlled in our factory under rigid inspection and testing procedures. Follow these instructions, and with proper care, your press should give many years of trouble-free service. - Page 12 CARVER Special Hydraulic Fluid (Catalog #2170) is supplied in sealed one pint or five gallon containers. Contact CARVER, INC. Parts Department for information. A premium grade of mineral base, high pressure, hydraulic oil with anti-wear and anti-foaming additives with an ISO viscosity rating of 32 cSt (Centistokes)at 40°C (105°F) to 49°C (120°F) with equivalent or greater specification of the...

-

Page 13: Section Five

SECTION FIVE ACCESSORY EQUIPMENT Thank you for the opportunity to supply CARVER equipment for your requirements. If there are any questions regarding the operation of this press or other CARVER accessories, please contact us for assistance. CARVER offers a wide range of accessory equipment to satisfy your specific application(s). -

Page 14: Section Six

RETURNED MATERIAL POLICY REDIT RETURNS Prior to the return of any material, authorization must be given by CARVER, INC. A RMS number will be assigned for the equipment to be returned. A reason for requesting the return must be given. -

Page 15: Section Seven

SECTION SEVEN WARRANTY WARRANTY RETURNS Prior to the return of any material, authorization must be given by CARVER, INC. A RMA number will be assigned for the part or equipment to be returned. Reason for requesting the return must be given. -

Page 16: Section Eight

SECTION EIGHT APPENDIX...

Need help?

Do you have a question about the 4350 and is the answer not in the manual?

Questions and answers