Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Brinkmann FKO PROFIBUS

- Page 1 Additional operating manual PROFIBUS fieldbus Type: FKO PROFIBUS Status: 24/07/2015 Original Additional operating instructions V1.7 DE Only valid with operating manual for the FKO Document number: DOC01.7_784xyz-0009 Operating manual for PROFIBUS fieldbus | 2015-07 | V1.7 EN...

- Page 2 The compilation is made without any guarantee. General note on gender equality BRINKMANN is aware of how language impacts on gender equality and always makes an effort to reflect this in documentation. Nevertheless, for the sake of readability we are unable to use non-gender-specific terms throughout and use the masculine form instead.

-

Page 3: Table Of Contents

Contents General information ................. 5 Information about documentation ......... 5 1.1.1 Other applicable documents ..........6 1.1.2 Storing the documentation ..........6 Notes in this manual ............7 1.2.1 Warnings ................ 7 1.2.2 Warning symbols used ............8 1.2.3 Signal words ..............8 1.2.4 Information notes ............. - Page 4 Conten ts 4.3.2 Direct access ..............41 4.3.3 Indirect access ............... 42 4.3.4 Parameter ..............43 Error detection and troubleshooting ..........52 Error word of application side ..........52 Error word of power side ..........53 EC declaration of conformity ............54 Operating manual for PROFIBUS fieldbus | 2015-07 | V1.7 EN...

-

Page 5: General Information

1. General information Thank you for choosing an FKO drive controller with PROFIBUS from BRINKMANN! Our FKO line of drive controllers is designed to be universally usable with all common motor types and bus systems. If you have any technical questions, please call our central service hotline: Tel.: +49 (0)2392 5006-0... -

Page 6: Other Applicable Documents

General informa tion 1.1.1 Other applicable documents This refers to all manuals that describe how to operate the drive controller system and any other manuals for the equipment used. 1.1.2 Storing the documentation Store this operating manual and all other applicable documents carefully so they are available when needed. -

Page 7: Notes In This Manual

General informa tion 1.2 Notes in this manual 1.2.1 Warnings The warnings refer to life-threatening dangers. Serious injuries possibly resulting in death may occur. Each warning consists of the following elements: DANGER Risk of death due to electrical shock! Death or serious injury! De-energise drive controller and secure it against being restarted. -

Page 8: Warning Symbols Used

General informa tion 1.2.2 Warning symbols used Danger Danger due to electrical shock and discharge Danger due to burns Danger due to electromagnetic fields 1.2.3 Signal words Signal words are used to identify the severity of the danger. DANGER Indicates a direct hazard with a high level of risk, which, if not avoided, will result in death or serious injury. -

Page 9: Information Notes

General informa tion 1.2.4 Information notes Information notes contain important instructions for the installation and problem-free operation of the drive controller. These must be followed at all times. The information notes also point out that failure to observe can result in damage to property or financial damages. -

Page 10: Symbols Used In This Manual

General informa tion 1.3 Symbols used in this manual Symbol Meaning 1., 1., 3. … Consecutive steps in a handling instruction Effect of a handling instruction Final result of a handling instruction List Fig.: 3 Symbols and icons used Abbreviations used Abbreviation Explanation... -

Page 11: Qualified Staff

Repairs may only be performed by authorised repair bodies. Independent and unauthorised intervention may result in death, injury or property damage. The warranty provided by BRINKMANN will be invalidated in such cases. External mechanical loads such as stepping on the housing are not... -

Page 12: Responsibility

General informa tion 1.6 Responsibility As a basic principle, electronic devices are not fail-safe. The operator and/or the contractor setting up the machine or system is responsible for ensuring that the drive switches to a safe state if the device fails. The “Electrical equipment of machines”... -

Page 13: Safety Instructions

General informa tion 1.7 Safety instructions The following warnings, precautionary measures and information are provided for your safety and serve to prevent damage to the drive controller and the components connected to it. This chapter contains warnings and information that are generally applicable when handling drive controls. They are split into general information, transport &... -

Page 14: General Information

This operating manual is an integral part of the product. It applies exclusively to the drive controller from K.H. Brinkmann GmbH & Co. KG. Keep the operating manual close to the drive controller so it is easily accessible to all users. -

Page 15: Device And System Description

2. Device and system description This chapter contains information on the scope of delivery for the drive controller and the function description. 2.1 PROFIBUS With the help of the PROFIBUS, devices from various providers can communicate without special adaptation. PROFIBUS differentiates between master and slave devices independently, so that multi-master operation is also possible. -

Page 16: Master / Slave Operation

Device and s ystem desc ription Data transfer rates The data transfer rate can be set in the master within a range from 9.6 kbit/s to 12 Mbit/s. The data transfer is selected when setting up the field bus and applies to all participants. -

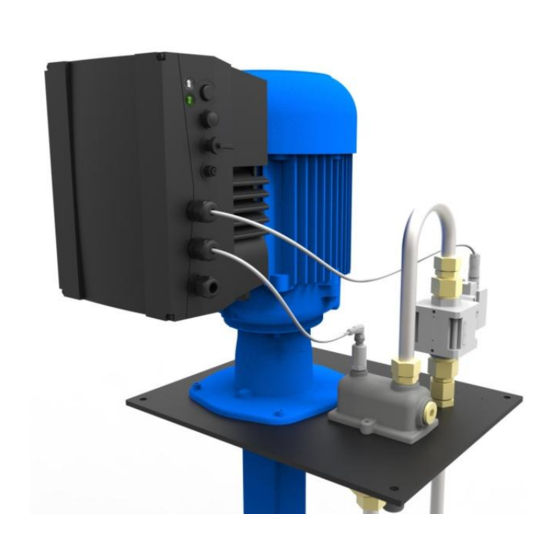

Page 17: Hardware Components

Device and s ys tem desc ription 2.3 Hardware components Hardware components for connecting the FKO to a PROFIBUS bus system: The FKO is fitted in the factory with the appropriate communication card. The FKO cannot be retrofitted or converted at a later date. Operating manual for PROFIBUS fieldbus | 2015-07 | V1.7 EN... -

Page 18: Interfaces On The Drive Controller

Device and s ystem desc ription 2.3.1 Interfaces on the drive controller The following connections can be found on the FKO with PROFIBUS interface card. Size A: Fig.: 5 BG connections. A "PROFIBUS" BG connections. A "PROFIBUS" Blind plug Control line PROFIBUS Potentiometer Grid connection... - Page 19 Device and s ys tem desc ription Sizes B - C Fig.: 6 BG connections. B - C "PROFIBUS" BG connections. B - C "PROFIBUS" Blind plug STO (mount the EMC threaded connection in the accessory pack) Control line Blind plug PROFIBUS Potentiometer Blind plug...

- Page 20 Device and s ystem desc ription Size D: Fig.: 7 BG connections. D "PROFIBUS" BG connections. D "PROFIBUS" Cable screw connection with blind plug Control line PROFIBUS Potentiometer Blind plug STO (mount the EMC threaded connection in the accessory pack) Blind plug STO (mount the EMC threaded connection in the accessory pack)

-

Page 21: Pin Assignment For Interfaces

Device and s ys tem desc ription 2.3.2 Pin assignment for interfaces Pin assignment on device side of M12 socket for PROFIBUS: PIN no. Signal + 5 V DC RxD/TxD-N / A-line (green) Ground RxD/TxD-P / B-line (red) Not used Housing Shielding Fig. -

Page 22: Installation

3. Installation The fieldbus line is exclusively connected via an M12 Y-distributor found on the front of the M12 connection socket. The PROFIBUS M12 Y distributor must demonstrate the M12 Y distributor following features: Terminating resistor 2× plugs 5-pin ... -

Page 23: Configuration Of The Drive Controller For Profibus

Installation 3.1 Configuration of the drive controller for PROFIBUS In order that the drive controller can be controlled by the fieldbus, the following basic parameters must be set using the FKOpc tool, MMI or PROFIBUS master: Set parameter 1.130 (target value source) to fieldbus "9" ... - Page 24 Installation Fig.: 9 Setting parameters via rotary switches" Switch 1 – for the unit position Switch 2 – for the tens position General instructions for addressing The addresses "0" are reserved in the General Diagnostic Tools, for example, programming devices. ...

- Page 25 Installation Both rotary switches (Switch 1/Switch 2) are set to the value "0" in the delivery state. Only in this state can addressing via the parameter 6.060 "Field bus address" take place. The default address 125 is active when the rotary switches (Switch 1/Switch 2) and the parameter are set to address "0".

-

Page 26: Setting The Address On The Communication Card

Installation 3.2.1 Setting the address on the communication card DANGER Risk of death due to electrical shock! Death or serious injury! De-energise drive controller and secure it against being restarted. IMPORTANT INFORMATION The address of an FKO must lie within the range from 2 to 125. Procedure 1. -

Page 27: Setting The Field Bus Address Via Rotary Switches Switch 1/Switch 2

Installation 4. Screw the cover of the drive controller back onto the housing (torque 4 Nm). 5. Switch the voltage supply for the drive controller on. The address of the FKO is set. 3.3 Setting the field bus address via rotary switches Switch 1/Switch 2 Address Settings... - Page 28 Installation Address Settings Address Settings DECIMAL Switch 2 Switch 1 DECIMAL Switch 2 Switch 1 Tab.: 1 Fieldbus address via rotary switches Switch 1/Switch 2 IMPORTANT INFORMATION The addresses marked in grey (0, 1, 126, 127) may not be used for addressing the FKO.

-

Page 29: Installing The Fko Gsd File

Installation 3.4 Installing the FKO GSD file A "device-specific information file" is required to use the FKO drive controller with PROFIBUS. Download the "PROFIBUS fieldbus for FKO" ZIP file from the download area on our website under the following link: www.brinkmannpumps.de/Support/Downloads/Frequenzumrichter Embed the GSD file as required by the PROFIBUS master you are using. -

Page 30: Accessing Data Via Profibus

4. Accessing data via PROFIBUS Data can be accessed via PROFIBUS both cyclically and non-cyclically (see chapter 4.3). Cyclic data is known as a process image. It is made up of data sent by the PROFIBUS master to the drive controller and from the drive controller to the PROFIBUS master. - Page 31 Accessing data via PROFI BUS The first two process variables (status word and actual frequency) cannot be parameterised and are always sent. The remaining 8 process variables can be configured using parameters 6.080 to 6.087. The "Process data Out" available can be found in chapter 4.1.3 "Process data Out".

- Page 32 Accessing data via PROFI BUS Frame Address Data type Designation Unit Description Process data Out 8 can be parameterised using 0x001C REAL FKOpc tool (parameter 6.085) (Analogue input 1) Process data Out 9 can be parameterised using 0x0020 DWORD* FKOpc tool (parameter 6.086) (Error word 1) Process data Out 10 can be parameterised using...

-

Page 33: Structure Of Fko Status Word

Accessing data via PROFI BUS 4.1.2 Structure of FKO status word The meanings of the individual bits of the FKO status word are described in the following table. Value Meaning Description Ready for engagement Grid voltage present, no fault Not ready for engagement Ready for operation No fault / HW enable set Not ready for operation... -

Page 34: Process Data Out Which Can Be Parameterised

Accessing data via PROFI BUS Value Meaning Description Device-specific Meaning not specified Device-specific Meaning not specified Device-specific Meaning not specified Device-specific Meaning not specified Motor current limit Motor current is limited Tab.: 3 FKO status word AG: Automation device 1 Deviation from standard 2 As of software version 03.61 3 As of software version 03.74 4.1.3... - Page 35 Accessing data via PROFI BUS Availab. Consec. Data in SW Designation Unit Description type version REAL Grid voltage Input voltage Intermediate circuit REAL current REAL Inner temperature ° C FC inner temperature Incremental encoder REAL only with encoder option speed Incremental encoder t.b.d.

-

Page 36: Cyclic Data Access - Process Data In

Accessing data via PROFI BUS Consec. Availab. Data in SW Designation Unit Description type verion. Customer-specific output Customer-specific soft PLC REAL 03.04 variable 3 output variable DWORD 03.05 Operating time in seconds Operating time in seconds DWORD 03.05 Power On cycles Power On cycles REAL 03.05... - Page 37 Accessing data via PROFI BUS The first two process variables (control word and target value) cannot be parameterised and are always expected. The remaining 4 process variables can be configured using parameters 6.110 to 6.113. The "Process data In" available can be found in chapter 4.2.2 "Process data In".

-

Page 38: Structure Of Fko Control Word

Accessing data via PROFI BUS 4.2.1 Structure of FKO control word The meanings of the individual bits of the FKO control word are described in the following table. IMPORTANT INFORMATION The control word is only accepted if bit 10 (control from AG) is set, otherwise the sent control word is rejected. - Page 39 Accessing data via PROFI BUS Value Meaning Description JOG (right) Not implemented Not implemented JOG (left) Not implemented Not implemented Control from AG Management via interface, control word valid Control word is rejected Device-specific Device-specific Device-specific Device-specific Device-specific Tab.: 6 Control word HLG: Ramp function generator Operating condition Deviation from standard...

-

Page 40: Process Data In Which Can Be Parameterised

Accessing data via PROFI BUS 4.2.2 Process data In which can be parameterised The remaining 4 process variables (2 – 6) can be parameterised with the help of the FKOpc tool using parameters 6.110 to 6.113. The available process variables of the parameter settings can be found in the following table. Consec. -

Page 41: Non-Cyclic Data

Accessing data via PROFI BUS 4.3.1 Non-cyclic data PROFIBUS principally has a slot and an address when accessing non- cyclical data. Both are 8 bit values. The index covers the number range from 0 – 255. The slot supports the values 0, 1 and 2. The addressing of the non-cyclical data can be carried out in 2 different ways. -

Page 42: Indirect Access

Accessing data via PROFI BUS 4.3.3 Indirect access The slot "0" and index "0" and "1" are used for indirect access. The reading and writing of the non-cyclical data is carried out here in 2 steps. The following depiction should be helpful to you in implementing the two steps. -

Page 43: Parameter

Accessing data via PROFI BUS 4.3.4 Parameter The following parameters can be accessed non-cyclically for reading and writing. IMPORTANT INFORMATION Changing a parameter value via the fieldbus includes direct EEPROM write access. INFORMATION The data below is listed sorted in ascending order by "Number*". PROFIBUS FKO parameter Slot... - Page 44 Accessing data via PROFI BUS PROFIBUS FKO parameter Name in Slot Index Parameter Number* Accepted Minimum Maximum Unit German Auto 1,181 2: Always acknowledgeme 1000 1,182 2: Always Auto ackn. no. Fixed frequency 2,050 2: Always mode Fixed frequency 2,051 2: Always -400 Fixed frequency...

- Page 45 Accessing data via PROFI BUS PROFIBUS FKO parameter Slot Index Parameter Number* Accepted Name in German Minimum Maximum Unit PID fixed nominal 3,065 2: Always value 4 PID fixed nominal 3,066 2: Always value 5 PID fixed nominal 3,067 2: Always value 6 PID fixed nominal 3,068...

- Page 46 Accessing data via PROFI BUS PROFIBUS FKO parameter Name in Slot Index Parameter Number* Accepted Minimum Maximum Unit German 4,054 2: Always AI2 filter time 0.02 4,060 2: Always AI2 function 4,063 2: Always AI2-phys unit 4,064 2: Always AI2 phys min -10000 10000 4,065...

- Page 47 Accessing data via PROFI BUS PROFIBUS FKO parameter Slot Index Parameter Number* Accepted Name in German Minimum Maximum Unit 4,194 2: Always Relay 1 off delay 10000 4,210 2: Always Relay 2 function 4,211 2: Always Relay 2 on -32767 32767 4,212 2: Always...

- Page 48 Accessing data via PROFI BUS PROFIBUS FKO parameter Name in Slot Index Parameter Number* Accepted Minimum Maximum Unit German 5,103 2: Always Techn.param.4 -9999999 9999999 5,104 2: Always Techn.param.5 -9999999 9999999 5,105 2: Always Techn.param.6 -9999999 9999999 5,106 2: Always Techn.param.7 -9999999 9999999...

- Page 49 Accessing data via PROFI BUS PROFIBUS FKO parameter Slot Index Parameter Number* Accepted Name in German Minimum Maximum Unit Target/actual value 6,070 2: Always dev. 6,071 2: Always Tolerance range 32767 6,072 2: Always Target comp. value 6,080 2: Always Process data Out 3 6,081 2: Always...

- Page 50 Accessing data via PROFI BUS PROFIBUS FKO parameter Name in Slot Index Parameter Number* Accepted Minimum Maximum Unit German 33,034 1: Ready Motor speed 80000 33,035 1: Ready Motor frequency 33,050 1: Ready Stator resistance Scatter 33,105 1: Ready inductivity 33,110 1: Ready Motor voltage...

- Page 51 Accessing data via PROFI BUS PROFIBUS FKO parameter Slot Index Parameter Number* Accepted Name in German Minimum Maximum Unit 34,226 2: Always PMSM start-up current 1000 34,227 1: Ready PMSM init. time PMSM start-up 34,228 1: Ready procedure 34,229 1: Ready PMSM start-up ramp 1000 34,230...

-

Page 52: Error Detection And Troubleshooting

5. Error detection and troubleshooting The errors from the application and power side can be issued in the Process data Out (see Chapter 4.1.3 "Process data Out which can be parameterised" / serial no. 11, 13). 5.1 Error word of application side The following section contains a list of possible error messages of the application. -

Page 53: Error Word Of Power Side

Error detec tion and troubl eshooting Bit. Error number Description External fault 1 External fault 2 Motor detection STO inputs plausibility Tab.: 9 Application error word 5.2 Error word of power side The following section contains a list of possible power side error messages. Bit. -

Page 54: Ec Declaration Of Conformity

EC declaration of conformity / Déclaration de conformité CE / Declaración de conformidad CE Hersteller / Manufacturer / Constructeur / Fabricante Brinkmann Pumpen, K. H. Brinkmann GmbH & Co. KG Friedrichstraße 2, D-58791 Werdohl Produktbezeichnung / Product name / Désignation du produit / Designación del producto Antriebsregler / Drive control / Convertisseur de fréquence / Regulador de accionamiento... - Page 55 Notes Operating manual for PROFIBUS fieldbus | 2015-07 | V1.7 EN...

- Page 56 BRINKMANN PUMPEN K.H. Brinkmann GmbH & Co. KG Friedrichstraße 2 58791 Werdohl Germany Tel. +49 (0)2392 5006-0 Fax +49 (0)2392 5006-180 sales@brinkmannpumps.de www.brinkmannpumps.de Operating manual for PROFIBUS fieldbus | 2015-07 | V1.7 EN...

Need help?

Do you have a question about the FKO PROFIBUS and is the answer not in the manual?

Questions and answers