Summary of Contents for McElroy 1LC

- Page 1 Operator’s Manual Fusion Machine Manual: CTS15901 Revision: C 12/18 Original Language: English...

- Page 2 Cancer and Reproductive Harm - www.P65warnings.ca.gov This product and other products could be protected by patents or have patents pending. All the latest patent information is available at patent.mcelroy.com...

- Page 3 The 1LC fusion machine is small and compact, and offers the benefit of McElroy's Patented Centerline Guidance System previously offered only in larger machines. The 1LC butt fuses 1/2" CTS to 1" IPS (16mm - 34mm) polyethlene pipe. If fusing other thermoplastic pipe materials, refer to the pipe manufacturer's fusion procedures or appropriate joining standard.

- Page 4 McElroy or has become damaged McElroy reserves the right to make any changes in or due to misuse, negligence or casualty, or has not been improvements on its products without incurring any operated or maintained according to McElroy’s printed...

-

Page 5: Table Of Contents

1LC Fusion Machine ........ - Page 6 Table of Contents Maintenance Checklist 1LC Fusion Machine Checklist ......5-1 Specifications...

-

Page 7: Safety Alerts

Follow all applicable federal, state, local, and industry specific regulations. McElroy Manufacturing, Inc. cannot anticipate every possible circumstance that might involve a potential hazard. The warnings in this manual and on the machine are therefore not all inclusive. -

Page 8: General Safety

Fusion Equipment Safety General Safety Safety is important. Report anything unusual that you notice during set up or operation. LISTEN for thumps, bumps, rattles, squeals, air leaks, or unusual sounds. SMELL odors like burning insulation, hot metal, burning rubber, hot oil, or natural gas. -

Page 9: Electrical Safety

Fusion Equipment Safety Electrical Safety Always ensure power cords are properly grounded. It is important to remember that you are working in a wet environment with electrical devices. Proper ground connections help to minimize the chances of an electric shock. Frequently inspect electrical cords and unit for damage. -

Page 10: Fusion Procedures

Fusion Equipment Safety Fusion Procedures Obtain a copy of the pipe manufacturer's procedures or appropriate joining standard for the pipe being fused. Follow the procedure carefully, and adhere to all specified parameters. NOTICE: Failure to follow pipe manufacturer's procedure could result in a bad joint. Always follow pipe manufacturer's procedures. -

Page 11: Overview

Overview Theory of Heat Fusion The principle of heat fusion is to heat two pipe surfaces to a designated temperature, and then fuse them together by application of force. This develops pressure which causes flow of the melted materials, which causes mixing and thus fusion. When the thermoplastic material is heated, the molecular structure is transformed into an amorphous condition. -

Page 12: 1Lc Fusion Machine

Overview 1LC Fusion Machine 1LC Fusion Machine Facer Heater Heater Sling Ratchet Wrench Case Heater The heater temperature is controlled by a microprocessor. The heater has a green indicator light which will flash on and off. This indicates that the controller is operating normally. It has a red indicator light. -

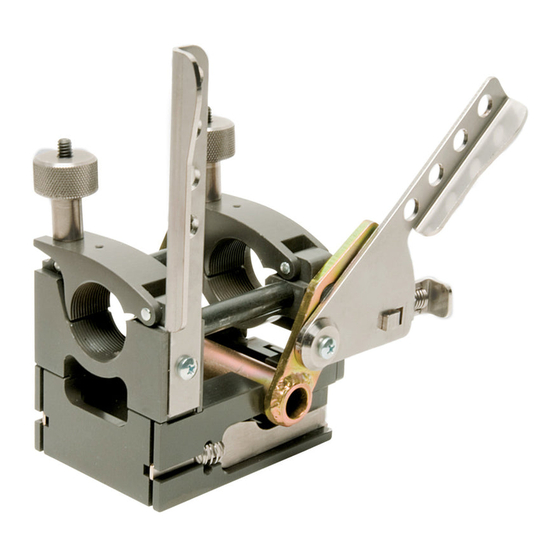

Page 13: Facer

Turn the ratchet counter-clockwise for facing. TX04120-7-9-10 Fusion Machine The fusion machine offers McElroy's Patented Centerline Guidance System for equal distribution of force around the joint. A 2 position handle for facing and for heat/fuse. The machine is equipped with a locking cam to maintain force during the cooling cycle. -

Page 14: Operation

Operation Read Before Operating Before operating this machine, please read this manual thoroughly, and keep a copy with the machine for future reference. The fusion procedures in this manual are for use with polyethylene pipe. If fusing other thermoplastic pipe materials, refer to the pipe manufacturer's suggested procedures or appropriate joining standard. -

Page 15: Loading Pipe Into Machine

Operation Loading Pipe Into Machine Clean the inside and outside of pipe ends that are to be fused. Ensure the locking cam is in the latched position. Open the upper jaws and insert pipe in each jaw with applicable inserts installed. Let the ends of the pipe protrude about 3/8" past the face of the jaws. -

Page 16: Check Alignment Of Pipe

Operation Check Alignment of Pipe Remove all pipe shavings. Do not touch the pipe ends. Bring the pipe ends together under sufficient force to overcome any pipe drag or friction in the system. Check for alignment and proper face off. If high/low (misalignment) exists, adjust by tightening the clamp on the high side and reface the pipe. -

Page 17: Inserting Heater

Operation Inserting Heater Heater is not explosion proof. Operation of heater in an explosive atmosphere without necessary safety precautions will result in serious ¡PELIGRO! injury or death. If operating in an explosive atmosphere, heater should be brought up to temperature in a safe environment, then unplugged before entering the explosive atmosphere for fusion. -

Page 18: Remove The Pipe From The Machine

Operation Remove the Pipe from the Machine When the cooling cycle is completed, relatch the cam lock, unclamp and remove the pipe from the machine. TX04117-7-9-10 3 - 5... -

Page 19: Maintenance

Maintenance Preventative Maintenance To insure optimum performance, the machine must be kept clean and well maintained. With reasonable care, this machine will give years of service. Therefore, it is important that a regular schedule of preventive maintenance be kept. Store machine inside, out of the weather, whenever possible. TX00428-8-10-95 Cleaning the Machine The machine should be cleaned, as needed with a soap and... -

Page 20: Clean Eyebolt Threads

Maintenance Clean Eyebolt Threads Keep the clamp knob eyebolt threads brushed clean. TX00435-9-13-94 Facer and Blades Inspect the facer blades for sharpness and damage. Blades can not be resharpened and should be replaced when dull or damaged. TX04118-7-9-10 Clean Heater Surfaces The heater must be kept clean and free of any plastic build-up, contamination and scratches. -

Page 21: Adjusting Heater Temperature

If the green indicator is not flashing then the controller may not be operating properly. If this occurs, disconnect power and have the heater repaired by an McElroy Authorized Service Center. The heater has a red indicator light on the handle at the bottom of the temperature scale. - Page 22 Maintenance Checklist 1LC Fusion Machine Checklist Item to Check Satisfactory Needs Repair Comments Repair UNIT Machine is clean Clamp knob bearings lubricated and move freely Movable jaw moves freely Locking cam works properly Guide rods are not damaged Clamping jaw and insert grooves are clean...

- Page 23 Specifications 1LC Fusion Machine Specification: Designed for 1/2" CTS - 1" IPS (16mm - 34mm) Dimensions: Width: 4.25" (108mm) Length: 5.25" (133mm) Height: 7.5" (191mm) Weight: 3.6 lbs. (1.6 Kg) Heater: 100 W, 100V-120V, 50/60Hz, 1Ph 100 W, 200V-240V, 50/60Hz, 1Ph Weight: 2.5 lbs.

- Page 25 About this manual . . . McElroy Manufacturing continually strives to give customers the best quality products available. This manual is printed with materials made for durable applications and harsh environments. This manual is waterproof, tear resistant, grease resistant, abrasion resistant and the bonding quality of the printing ensures a readable, durable product.

Need help?

Do you have a question about the 1LC and is the answer not in the manual?

Questions and answers