Advertisement

Quick Links

Advertisement

Summary of Contents for Dinghua DH-A1L-C

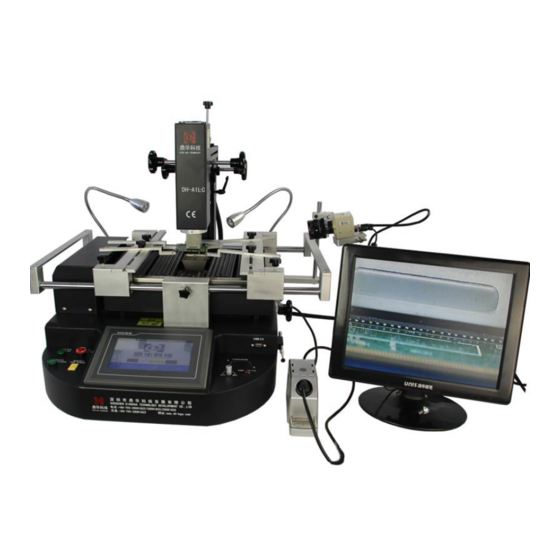

- Page 1 DH-A1L-C BGA rework station manual...

- Page 2 Science and technology are the primary productive forces, with over years of hardworking, Dinghua has owned core technology of temperature controlled and 38 patents and finished the development and production of manual, semi-auto and automatic series and realized the second revolution from traditional hardware combination to integrated control.Our...

- Page 3 三 、 Safety Precautions of rework station 1、 Do not use fans or other devices directly to the repair station hair when it works, otherwise it will lead to negative differential heating plate surface , burn the workpiece. 2、 When turned on, high-temperature heating zone can not be any direct contact with the object , it may cause fire or explosion ,and the PCB workpiece should be placed on the PCB support shelves.

- Page 4 (二)Features Name Functions Use ways limit the lowest position of the Limit bar Rotate to the right place upper heating lock the upper zone of up and Tension adjustment knob Rotate the knob down ,before and after Before and after adjustment Adjust the upper zone of before Rotating the handle handle...

- Page 5 clamping the PCB lower temperature zone Adjust the lower nozzle Rotating the handle height adjustment handle distance from the PCB board Emergency stop button Emergency stop Press the button light button light switch Press the button The upper heating zone generate upper hot air Adjust the upper zone of the Adjust the handle up and down...

- Page 6 (三)Specification: Total Power 4900W Top heater 800W Second heater 1200W,IR preheating 2700w,digital thermostat soldering Bottom heater iron 80W AC220V± 10% 50/60Hz power Dimensions L650× W700×H650 mm V-groove, PCB support can be adjusted in any direction with external Positioning universal fixture K Sensor, Closed loop Temperature control ±...

- Page 7 9. Collocating with sound control "early warning" function. It can warn workers to make some relative preparation 5-10 seconds before the completion of uninstalling or welding. Cooling system will start after vertical wind stopped heating. When the temperature drops to normal temperature, the cooling process will stop automatically, so that the machine will not be aging after temperature heated up.

- Page 8 put out, withdraw the hot wind head.Finally, take away the PCB board from the heating zones. (1) null welding: Because of counterpoint by hand will cause deviation between chip and welding plate, surface tension of tin ball will make BGA chip and welding plate in the process of automatic correction. Once heating, BGA falls not evenly, which cause the chip drops not evenly.If stop reflowing at this time, the chip will not fall normally,which will cause th phenomenon of empty welding and false welding.So you need to extent time of third 、forth temperature zones or add the bottom...

- Page 9 In this interface, the temperture can be changed and saved. User can set the heating temperture, the constant time and the heat speed according to the requirements of the production process. The machine can be mass storage temperature curve.User can store a a variety of manufacturing process parameters in the system.when replaceing of the production process, direct call to the parameters saved in the system, equivalent to formulation saved in the system.There are different heating temperature with different products,it can save various kinds of paraments in the different formulation,and it will be easy to use it when changed...

- Page 10 If have to input new parameter, click the button of “curve choose”, and then click on the numerical place, the input button will appear. Input the parameter you need, press“ENTER” key.When temperature parameters Settings of these three temperature zones are finished, click “save curve”, then all parameters you have set are all saved.

- Page 11 And it also can be changed and saved by “curve chooses”. Click „Start‟,the whole station starts to heating,and the working curve is showing the current parameter,and it will also clear the previous curve showed on screen.The whole heating will complete until the upper setting temperature or the upper part of the heating rate is zero,and just the machine stops running,with the alarm ringing, if the cooling vacuum interface has been set up within the cooling and vacuum state, then these two output also work.if click „stop‟...

- Page 12 Lead temperature curve welding 41*41 BGA welding temperature setting Welding Welding Preheating Constant Heating Reduction Upper heating Constant time Bottom heating Constant time preheating Constant time Speed rate 38*38 BGA welding temperature setting Welding Welding Preheating Constant Heating Reduction Upper heating Constant time...

- Page 13 Welding Welding Preheating Constant Heating Reduction Upper heating Constant time Bottom heating Constant time preheating Constant time Speed rate Above is lead type BGA chip reference temperature. Lead-free temperature curve welding 41*41 BGA welding temperature setting Welding Welding Preheating Constant Heating Reduction Upper...

- Page 14 38*38 BGA welding temperature setting Welding Welding Preheating Constant Heating Reduction Upper heating Constant time Bottom heating Constant time preheating Constant time Speed rate 31*31 BGA welding temperature setting Welding Welding Preheating Constant Heating Reduction Upper heating Constant time Bottom heating Constant time...

-

Page 15: Concluding Remarks

areas depend on the PCB board size. 2. You should set different temperature curves when repair different BGA,each temperature should not higher than 300℃;Lead-free rework setting can refer to welding temperature curve of BGA tin bead. 3. When demount BGA,the cooling fan and vacuum should be setted to automatic transmission,the buzzer will warn automatically when temperature curve runs to the end.Meanwhile, remove the BGA from PCB board with vacuum pen, and then remove the PCB board from the positioning frame. -

Page 16: Packing List

Packing list: Item specification Unit BGA rework station DH-A1L-C Vacuum sucker Instruction manual DH-A1L-C COPY Hot-air nozzle Upper nozzle 31*31 38*38 41*41 bottom nozzle 55*55 34*34 Shaped clip Plum knob Supporting screw Temperature sensor CCD camera system Display screen+camera+support www.HKLRF.com...

Need help?

Do you have a question about the DH-A1L-C and is the answer not in the manual?

Questions and answers