Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for KIAM Sherwood KA500

- Page 1 Kiam Power Products Kiam Sherwood KA500 Petrol Earth Auger Instructions Manual Read instructions manual before use! Equipmart Ltd Kiam House Birchill Road Knowsley Ind. Park North Merseyside L33 7TD United Kingdom T: 0044 151 548 5500 © Equipmart Ltd F: 0044 151 548 5599...

-

Page 2: Table Of Contents

Contents Parts location ................Specifications ................Warning labels on the machine ..........Symbols on the machine ............For safe operation ..............Setup ..................Fuel ................... Operation .................. Maintenance ................Storage ..................Troubleshooting guide .............. Disposal ..................Spare parts ................Warranty ................... SAFETY FIRST Instructions will contain warnings within this manual, they will be marked with a symbol concern-... -

Page 3: Parts Location

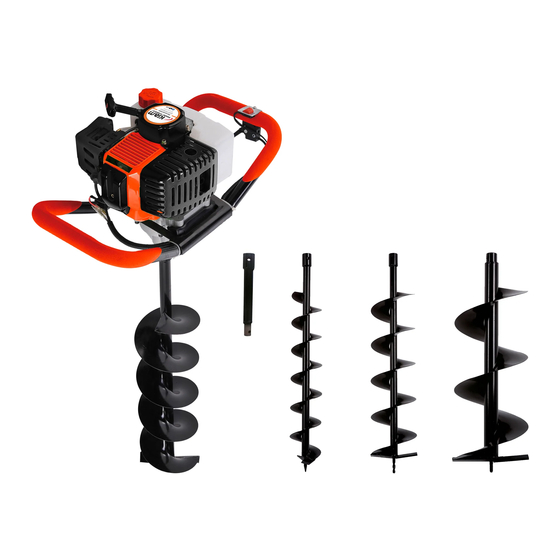

1. Parts location (1) Left grip (6) Throttle trigger (11) Throttle cable (2) Angle transmission (7) Right grip (12) Primer (3) Engine (8) Drill (option) (13) Choke lever (4) Fuel tank (9) Handle (14) Air cleaner cover (5) Starter knob (10) Stop switch 2. -

Page 4: Warning Labels On The Machine

3. Warning labels on the machine If warning label peels off or becomes soiled and impossible to read, you should contact the dealer from which you purchased the product (1) Warning / Attention to order new labels and affix them in the required location(s). -

Page 5: For Safe Operation

5. For safe operation gases contain dangerous carbon 1. THIS MACHINE CAN CAUSE monoxide. SERIOUS INJURIES. Read this 2. Never use the product, manual carefully until you com- a. when the ground is slippery pletely understand and follow all or when you can’t maintain a safety and operating instruc- steady posture. - Page 6 Kiam dealer. When work is to be performed simultaneously by two or more people, care should also be...

- Page 7 Kiam mark and recom- fuel from the fuel tank. If doing so, mended for the unit. fuel might leak from the tank dur- 5.

-

Page 8: Setup

6. Setup A Package contains the items as illustrated. 200mm INSTALLING THE DRILL 1. Put the drill onto the auger output shaft. 2. Insert the screw into the hole on the head of drill and lock it with a nut. (1) PTO shaft (3) Screw (2) Drill... -

Page 9: Fuel

3. Fasten the fuel cap securely and wipe up any fuel • The engines are lubricated by oil specially formulated spillage around the unit. for air-cooled 2-stroke petrol engine use. If Kiam 2-stroke oil is not available, use a red semi-synthetic 2-stroke oil. 1. Select clear flat ground for fueling. -

Page 10: Operation

8. Operation STARTING ENGINE IMPORTANT Avoid pulling the rope to its end or returning it by releas- WARNING ing the knob. Such actions can cause starter failures. The drill will start moving when the engine starts. 7. Move the choke lever downward to open the choke. 1. -

Page 11: Maintenance

Do not modify the drill or dismantle the engine. filter or if continually operated with damaged filter. • When replacing parts use Kiam original parts. • FUEL FILTER AIR FILTER After every 25 hours of operation, empty the fuel tank, •... -

Page 12: Storage

9. Maintenance IMPORTANT EXHAUST • If the fuel filter is clogged, the engine speed may be WARNING limited or speed fluctuations may occur. • If the engine is operated without a fuel filter, dirt will Inspect the exhaust regularly for loose fasteners, •... -

Page 13: Troubleshooting Guide

11. Troubleshooting Guide Case 1. Starting failure fuel tank incorrect fuel drain it and use correct fuel fuel filter fuel filter is clogged clean carburetor adjustment screw out of normal range adjust to normal range sparking (no spark) spark plug is fouled/wet clean/dry plug gap is incorrect correct (GAP: 0.65 mm) -

Page 14: Warranty

The purchaser is responsible for all related expenses (parts, labour and return costs) if the product is not covered under warranty. Original receipt must be included when returning to: Kiam Power Products Kiam House Birchill Road Knowsley Ind. Park North...

Need help?

Do you have a question about the Sherwood KA500 and is the answer not in the manual?

Questions and answers