Table of Contents

Advertisement

Quick Links

P.O. #:

CONTENTS

INTRODUCTION ..................................................................................................................................................................................... 1

SAFETY INSTRUCTIONS ...................................................................................................................................................................... 3

RECOGNIZE SAFETY INFORMATION ........................................................................................................................................... 3

UNSAFE LIFTING APPLICATIONS FOR CER MAGNETS .............................................................................................................. 4

AVOID A REDUCTION OF LIFTING CAPACITY .............................................................................................................................. 5

SAFETY PERSON ............................................................................................................................................................................ 5

IMPORTANT FACTS FOR THE OPERATION OF LIFT MAGNETS ...................................................................................................... 6

SAFETY RULES ..................................................................................................................................................................................... 8

RECOMMENDED LIFTING PROCEDURES ........................................................................................................................................ 10

OPERATING INSTRUCTIONS ..............................................................................................................................................................11

ON-BOARD operation instructions ..............................................................................................................................................11

REMOTE operating instructions ................................................................................................................................................. 12

GUIDELINES FOR THE REDUCTION OF THE RATED LIFTING CAPACITY .................................................................................... 13

LIFTING GUIDELINES (PLATE) CER05-CER09 ........................................................................................................................... 14

LIFTING GUIDELINES (PLATE) CER12-CER20 ........................................................................................................................... 15

DUTY CYCLE ................................................................................................................................................................................. 16

INSPECTION AND MAINTENANCE INSTRUCTIONS ........................................................................................................................ 17

SPECIFICATION & PARTS LIST .......................................................................................................................................................... 18

REPAIRS ....................................................................................................................................................................................... 19

CER05-CER12 Replacement Parts List ......................................................................................................................................... 20

CER16 & CER20 Replacement Parts List ...................................................................................................................................... 21

INTRODUCTION

Thank you for purchasing this Walker Magnetics Product. If used and maintained properly, it should serve for many years.

Thousands of Walker Magnetics lift magnets are in service today performing safe, fast, and efficient magnetic material

handling applications. It is often the only way for one person to load, transport, and unload material.

Walker Magnetics Products have proven to be among the best designed and safest in the industry. Note that if used

improperly, any CER magnet can be rendered inefficient and unsafe. It is absolutely essential that anyone who uses this

lifting magnet and is responsible for its application be trained on how to use it correctly.

READ THIS MANUAL CAREFULLY TO LEARN HOW TO OPERATE AND MAINTAIN THE MAGNET. FAILURE TO DO

SO COULD RESULT IN SERIOUS INJURY TO YOURSELF AND PEOPLE IN THE AREA.

THIS MANUAL SHOULD BE CONSIDERED A PERMANENT PART OF THE MAGNET AND SHOULD ALWAYS BE

AVAILABLE TO ALL OPERATORS AND REMAIN WITH THE MAGNET IF IT IS RE-SOLD.

To request additional copies of this manual, call 1-800-WMAGNET in the USA.

800-WMAGNET

O

peratiOns

Cer e

leCtrOMagnetiC

Order #:

M

Cer05

Odels

M

anual

l

ifting

TOLL FREE: 800.WMAGNET

Part #:

Cer20

thrOugh

M

agnet

1 of 21

Advertisement

Table of Contents

Summary of Contents for IMI WALKER CER05

-

Page 1: Table Of Contents

peratiOns anual Cer e leCtrOMagnetiC ifting agnet TOLL FREE: 800.WMAGNET P.O. #: Order #: Part #: Cer05 Cer20 Odels thrOugh CONTENTS INTRODUCTION ..................................... 1 SAFETY INSTRUCTIONS ..................................3 RECOGNIZE SAFETY INFORMATION ............................3 UNSAFE LIFTING APPLICATIONS FOR CER MAGNETS ......................4 AVOID A REDUCTION OF LIFTING CAPACITY .......................... - Page 2 INTRODUCTION CER electromagnetic lifting magnets are ideally suited for in-plant handling of steel plate, fl at stock, castings, forgings, or machined components in all types of industrial plants, machine shops, fabricating shops and steel warehouses. Handling of loose parts such as nuts and bolts is also a popular application for the CER family of magnets.

-

Page 3: Safety Instructions

SAFETY INSTRUCTIONS RECOGNIZE SAFETY INFORMATION The following indications are provided as alerts to special considerations: DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury. These Hazard Red Background, White Letters Signal Words WARNING indicates a hazardous situation which, if Deserve your not avoided, could result in death or serious injury. -

Page 4: Unsafe Lifting Applications For Cer Magnets

SAFETY INSTRUCTIONS ( CONTINUED Danger always exists when loads are transported by lifting devices, especially when the equipment is not being used properly or is poorly maintained. Special safety precautions apply to the operation, inspection, and maintenance of the Walker Lift Magnets. Proper lifting knowledge and techniques are the responsibility of the operator. -

Page 5: Avoid A Reduction Of Lifting Capacity

SAFETY INSTRUCTIONS ( CONTINUED TO AVOID A REDUCTION OF LIFTING CAPACITY DANGER To Avoid any Reduction of Lifting Capacity: • The lifting surfaces of the magnet and the area of the load where the magnet will be located must be clean, smooth, fl at and free of nicks and burrs. •... -

Page 6: Important Facts For The Operation Of Lift Magnets

IMPORTANT FACTS FOR THE OPERATION OF LIFT MAGNETS LOAD CHARACTERISTICS OTHER THAN JUST WEIGHT MUST BE CONSIDERED IN ORDER TO DETERMINE THE LOAD THAT ANY MAGNET CAN LIFT. This statement is true for all lifting magnets because they all operate using the same fundamental laws of physics. - Page 7 IMPORTANT FACTS FOR THE OPERATION OF LIFT MAGNETS 3. LOAD ALLOY Low carbon steels, such as SAE 1020 steel, are nearly as good conductors of magnetic force as pure iron. However, many other alloys contain non-magnetic materials which reduce the ability of magnetic force to flow into the load.

-

Page 8: Safety Rules

SAFETY RULES OPERATOR INSTRUCTIONS NEVER attempt to operate this lift magnet without reading and understanding the OPERATOR’S MANUAL & SAFETY INSTRUCTIONS. Check the condition of the magnet prior to every lift. WIPE clean the bottom of the magnet and the area on the load where the magnet will be locat- ed. - Page 9 SAFETY RULES ( CONTINUED Check to be sure no one is near the load to be lifted. Inform others in the area that a lift is to be- Lift and move the load SMOOTHLY. Avoid jarring gin. Lift the load 2 to 3 inches (50 to 75 mm) and and swinging the load while it is in transit.

-

Page 10: Recommended Lifting Procedures

RECOMMENDED LIFTING PROCEDURES SAFETY HOOK LATCH Always use a safety hook latch onto the crane hook to hold the magnets. STAY CLEAR OF THE LOAD Guide the load by pushing or pulling the edges of the load. Stay clear of the load at all times. PLATE LIFTING Position the magnet so that it is centered on the plate. -

Page 11: Operating Instructions

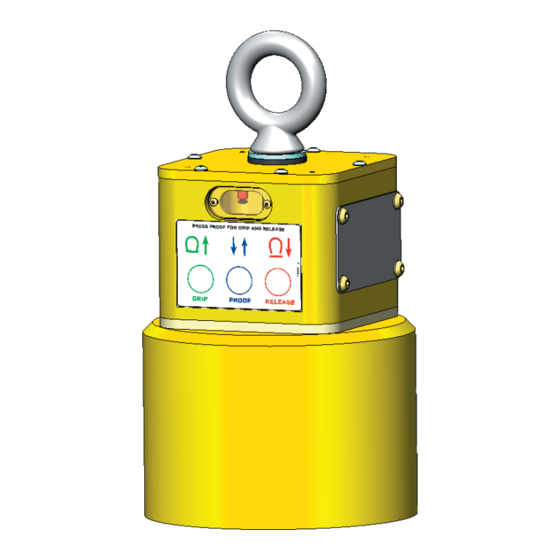

OPERATING INSTRUCTIONS 1. Local Push Button Operation GRIP MODE To energize the magnet, press and hold the GRIP and PROOF buttons*. Hold them both until the green ring of the GRIP button illuminates. The magnet is now in the full “ON” or energized condition. -

Page 12: Remote Operating Instructions

OPERATING INSTRUCTIONS CONT. 2. Remote Control Operation A. The remote control duplicates the functions of the local push buttons on the magnet. The system utilizes Infrared (I/R) light to communicate with the magnet to minimize interference to/ from radio frequency remote controls used elsewhere in the user’s facility. B. -

Page 13: Guidelines For The Reduction Of The Rated Lifting Capacity

GUIDELINES FOR REDUCTION OF RATED LIFT CAPACITY Each magnet model is rated for a different weight limit. Load characteristics will affect the lifting capacity of the magnets. The lifting guidelines for the various models are shown on the following pages. The Lifting Guidelines tables show the effect of air gap, load thickness, load length, and load width on lifting capacity. -

Page 14: Lifting Guidelines (Plate) Cer05-Cer09

LIFTING GUIDELINES (PLATE) CER05, CER07, and CER09 (plate) TYPE OF SURFACE CONDITION RUST OR SCALE CLEAN & SMOOTH IRREGULAR OR ROUGH Similar to a Flat Hot Similar to a Flat Similar to a Flat Smooth Rolled MAGNET LOAD (32 micro-inch RMS) Cut File Steel Surface MODELS... -

Page 15: Lifting Guidelines (Plate) Cer12-Cer20

LIFTING GUIDELINES (PLATE) CER12, CER16, and CER20 (plate) TYPE OF SURFACE CONDITION RUST OR SCALE CLEAN & SMOOTH IRREGULAR OR ROUGH Similar to a Flat Hot Similar to a Flat Similar to a Flat Smooth Rolled MAGNET LOAD (32 micro-inch RMS) Cut File Steel Surface MODELS... -

Page 16: Duty Cycle

DUTY CYCLE DUTY CYCLE DO NOT EXCEED THE RATED 50% DUTY CYCLE OF THESE MAGNETS. Exceeding the duty cycle will result in reduced lifting capacity, and a shorter magnet life. Duty cycle rating (D.C.%) is defined as: (Time On x 100) ÷ (Time Off + Time On) = D.C. % This is expressed as a percent Maximum time on is specified as 10 minutes To maximize the effectiveness of the magnet, keep the power off when the magnet is not in use. -

Page 17: Inspection And Maintenance Instructions

INSPECTION AND MAINTENANCE INSTRUCTIONS EVERY LIFT Keep the lifting surfaces of the magnet CLEAN, SMOOTH, FLAT, FREE OF RUST and any FOREIGN MATERIALS. Nicks and burrs on the lifting surfaces will reduce the lifting capacity. If burrs occur, they can be removed by filing them away. However, care must be taken to protect the neighboring lifting surfaces. -

Page 18: Specification & Parts List

SPECIFICATION AND PARTS LIST SPECIFICATIONS Model No. CER05 CER07 CER09 CER12 CER16 CER20 Working Load Limit 0-600 0-1,200 0-2,400 0-4,000 0-7,250 0-10,500 (LBS) Power 1048 (Watts) Net Wt. (LBS) 10.95” 11.75” 12.50” 12.50” 15.25” 16.38” Diameter 5.25” 6.75” 9” 12” 16”... -

Page 19: Repairs

REPAIRS For repair of a CER lift magnet, contact Walker Magnetics for the nearest Authorized Service Center TOLL FREE at 1-800-W-MAGNET. A return material authorization number will be issued along with the address of the nearest Service Center. The magnet, after receipt by the Service Center will be inspected and a free estimate of repair charges will be provided. -

Page 20: Cer05-Cer12 Replacement Parts List

SPECIFICATION AND PARTS LIST CER05 THRU 12 Replacement Parts List PART NO. ITEM PART DESCRIPTION CER05 CER09 CER09 CER12 I/R LENS 39-DD16797 39-DD16797 39-DD16797 39-DD16797 PLUG, TWIST LOCK 603950 603950 603950 603950 RECEPTACLE, TWIST LOCK 603949 603949 603949 603949 CORD GRIP 17-0014 17-0014 17-0014... -

Page 21: Cer16 & Cer20 Replacement Parts List

SPECIFICATION AND PARTS LIST CER16 & CER20 Replacement Parts List ITEM PART DESCRIPTION PART NO. 10-5052 COILED CORD 603950 PLUG, TWIST LOCK 603949 CONNECTOR BODY, TWIST LOCK 17-0014 CORD GRIP 15-0128 PUSH BUTTON (GREEN) 15-0127 PUSH BUTTON (RED) 900561 OVERLAY (REVISION A) 39-DD16797 LENS 30-6064... - Page 22 ALWAYS STAY CLEAR OF THE LOAD Guide the load by pushing or pulling the edges. This keeps your entire body clear of the load at all times. DO NOT guide the load by pushing or pulling the magnet. NEVER get in a position where you could get hit with the load if it is dropped.

Need help?

Do you have a question about the WALKER CER05 and is the answer not in the manual?

Questions and answers