Summary of Contents for Cadet CDT7

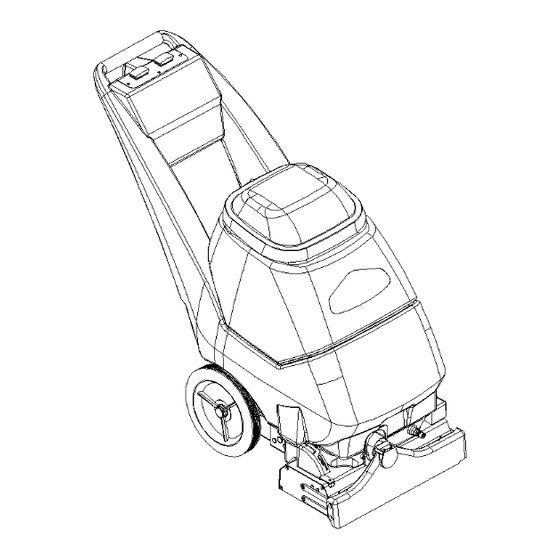

- Page 1 CARPET EXTRACTOR MODEL: CDT7 10080220 86038220 04/26/11 Read these instructions before operating the machine Operating Instructions 3146518...

-

Page 2: Machine Data Log/Overview

Thank you for purchasing a Windsor product. Warranty registration is quick and easy. Your registration will allow us to serve you better over the lifetime of the product. To register your product go to: www.windsorind.com/WarrantyRegistration.aspx For customer assistance: 1-888-444-7654 CADET 86038220... -

Page 3: Table Of Contents

Frame Assembly..5-1 Brush Assembly..5-3 Pump Assembly(prior to SN)..5-5 Pump Assembly ... 5-7 Vacuum Shoe Assembly... 5-9 Control Panel Assembly... 5-11 Solution Tank Assembly..5-13 Recovery Tank Assembly..5-15 Suggested Spare Parts/Notes ... 5-17 CADET 86038220... -

Page 4: How To Use This Manual

KIT INSTRUCTIONS which came with the kit. It contains replacement parts numbers needed for ordering future parts. NOTE: The number on the lower left corner of the front cover is the part number for this manual. CADET 86038220... -

Page 5: Grounding Instructions

This machine is suitable for commercial use, for example in hotels, schools, hospitals, factories, shops and offices for more than normal housekeeping purposes. Maintenance and repairs must be done by qualified personnel. If foam or liquid comes out of machine, switch off immediately. SAVE THESE INSTRUCTIONS CADET 86038220... -

Page 6: Importantes Mesures De Sécurité

L’entretien et les réparations de la machine doivent être effectuées par un personnel qualifié. Si de la mousse ou du liquide sort de la machine, la mettre hors tension immédiatement. CONSERVER CES INSTRUCTIONS CADET 86038220... -

Page 7: Hazard Intensity Level

WHEN SERVICING MACHINE: Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the machine. Use manufacturer approved replacement parts. HAZARD INTENSITY LEVEL Please take the necessary steps to train the machine operating CADET 86038220... -

Page 8: Degrés De Risques En Cas De Danger

LORS DE L’ENTRETIEN DE LA MACHINE : Éviter les parties amovibles. Ne pas porter de vêtements amples, tels que des vestes, des chemises ou des vêtements avec manches lors de l’utilisation de la machine. Utiliser les pièces détachées Windsor homologuées. CADET 86038220... -

Page 9: Extension Cords

: si elle ne correspond pas à la prise murale, faites installer une prise adéquate par un électricien qualifié. Utilisez-le uniquement sur des réceptacles protégés GFCI. CADET 86038220 Metal Screw Adaptor Grounded FIGURE B... -

Page 10: Technical Specifications

SOLUTION CAPACITY: 7 gallons (26.5ltr) RECOVERY CAPACITY: 7 gallons (26.5ltr) BRUSH SPEED: 1000 rpm 34” (86.36cm) 41” (104cm) CADET 86038220 GENERAL DIMENSIONS/WEIGHT Vacuum shoe: 17” (43.18 cm) cast aluminum with spring loaded down pressure WHEELS: (2) 10” dia. (25 cm) wheels by 2”... -

Page 11: Controls/Component Location

6. Brush Motor Circuit Breaker. 6 amp. Breaker protecting brush motor. 7. Vacuum Motor Circuit Breaker. 15 amp. Breaker protecting vacuum motor. 8. Recovery Dump Hose. Facilitates draining dirty cleaning solution. 9. Solution Dump Hose. Facilitates draining excess cleaning solution from solution tank. CADET 86038220... - Page 12 4. Recovery Tank. Used to collect dirty cleaning solution. 5. Solution Tank. Used to hold cleaning solution. 6. Recovery Tank Dome. 7. Vacuum Shoe. 8. Brush Housing. 9. Front Lifting Handle. 10. Cleaning Solution Filter. CADET 86038220...

- Page 13 CONTROLS/COMPONENT LOCATIONS 1. Solution Intake Cover. 2. Vacuum Intake Cover. 3. Float Shut-Off. 4. Clean-Out Opening. 5. Pour Spout. 6. Lift Handle. CADET 86038220...

-

Page 14: Filling Operation

FILLING OPERATIONS RECOVERY TANK FILLING THE CADET NOTE: Use clean bucket of water to fill solution tank Do not put defoamer, solvents, spotter or prespray chemicals in the solution tank. Do not allow water to spill into vacuum motor inlet. -

Page 15: Operations

Adjust brush to proper setting. Note: For good operation the brush must skim the carpet. If circuit breaker trips raise 1/8in brush to prevent damage to motor or carpet. (3mm) STEP Turn on both Vacuum and Pump motor switches (“ON”=“I”). CADET 86038220 OPERATIONS... - Page 16 The continuous setting allows the operator to set the switch in the “on” position with one touch, and is typically used in large areas where long cleaning passes are made. STEP STEP STEP INTERMITTENT CONTINUOUS CADET 86038220...

-

Page 17: Cleaning Procedure

Overlap brush contact area approximately 1inch. During operation, observe the following: The STEP SOLUTION Cadet is equipped with clear internal covers to INTAKE COVER facilitate operator viewing of dirty solution and vacuum air flow. During operation, observe the vacuum intake cover. - Page 18 To speed drying, use a Windblower™ fan. Empty recovery tank by releasing dump hose. Use a hose with cold water to clean out the recovery tank. Also drain solution tank after each use. STEP STEP STEP STEP RECOVERY DRAIN CADET 86038220 SOLUTION DRAIN...

-

Page 19: Accessory Tool Usage

1 ½ inch hose cuff into hole. STEP Turn on Pump and Vacuum Switch. Note: Be sure intermittent/continuous switch is in center (off) position and brush is in storage position. STEP Squeeze handle on accessory tool to begin cleaning. CADET 86038220 3-10... -

Page 20: Maintenance

Check cables for fraying Check the spray bar (manifold) for damage; replace if broken or bent Check condition of vac shoe and frame for damage Check overall performance of machine Check vac motor carbon brushes DAILY WEEKLY CADET 86038220 QUARTERLY... -

Page 21: Periodic Maintenance

Then snap bearing end (opposite end) of brush into retaining clip. Check cooling air screen (located on frame behind left wheel) for lint or debris. Check float and shut-off screen and clean as necessary. NOTE: Always store machine with brush in “Store” position. CADET 86038220 MAINTENANCE... -

Page 22: Vacuum Motor Replacement

Periodically check the length of the carbon brushes. Replace both carbon brushes when either is less than 3/8" (9.5mm) long. CADET 86038220 WARNING: The green ground wire must be attached for safe operation. -

Page 23: Belt Replacement

(p/n 62759) to the brush housing to remove belt. NOTE: All components associated with driving the brush will come out with the side plate. 7. Reverse process to install belt. 86249420 PRV NO. 62759 86227350 PRV NO. 05016 CADET 86038220 MAINTENANCE... -

Page 24: Solution Pump Replacement

3. Remove the (2) screws that fasten the solution tank to the frame, and tilt tank back to expose the inside of the frame. 4. Remove solution hoses from fittings in pump. 5. Remove the (2) screws that fasten the pump to the frame. 6. Reverse process to install pump. CADET 86038220... -

Page 25: Wiring Diagram

WIRING DIAGRAM 86268450 86268830 PRV NO. 88332 PRV NO. 88636 86266890 PRV NO. 88655 86004480 PRV NO. 41353 CADET 86038220... -

Page 26: Frame Assembly

FRAME ASSEMBLY CADET 86038220 03/16/07 SEE SOLUTION TANK... - Page 27 CLAMP, 2.0” WORM GEAR SCR, 1/4-20 X ½ HHCS PLTD SCR, 1/4-20 X 1 PPHMS SS PIN, ROLL 1/8” X 1.0”L SCR, 1/4-20 X 1.25 PPHMS SS NUT, 1/4-20 HEX W/ STAR WASHER CADET 86038220 03/16/07 FRAME ASSEMBLY SERIAL NO. NOTES: FROM 100046610...

-

Page 28: Brush Assembly

BRUSH ASSEMBLY CADET 86038220 03/16/07... - Page 29 SPACER, .81 X 1.06 X .125 PULLEY ASM, BRUSH DRIVER ASM, BRUSH BRUSH ASM, 15 IN ADAPTER, BRUSH BRG. DIE CAST BEARING, R6 3/8 ID BRUSH BEARING ASM. KIT, BRNG/ADPTR EXTRCTR CADET 86038220 BRUSH ASSEMBLY SERIAL NO. NOTES: FROM 1000090563 1000090563 1000090563...

-

Page 30: Pump Assembly(Prior To Sn)

PUMP ASSEMBLY PRIOR TO SERIAL NO. 1000166663 18 1 (SEE SOLUTION TANK) CADET 86038220 03/16/07... -

Page 31: Pump Assembly

WIRE, 22" GRN/18 76011 X 76011 HOSE, 3/8 URETHANE X 29" HOSE, 3/8 NYLON X 6" HOSE, 1/4 URETHANE X 6" SCREEN, INTAKE HOSE, 3/8 ID NYL11 YLW X 29” CADET 86038220 03/16/07 PUMP ASSEMBLY SERIAL NO. NOTES: FROM 1000029065... - Page 32 PUMP ASSEMBLY FROM SERIAL NO: 1000166663 (SEE SOLUTION TANK) CADET 86038220 03/16/07...

- Page 33 HOSE, 3/8 OD X 1/4 ID URTHN X 22" HOSE, 1/4 ID NYLON X 5" SCREEN, INTAKE HOSE, 3/8 ID NYLON YLW X 17” DUCT, 1/2 ID SPLT FLX X 16” CADET 86038220 03/16/07 PUMP ASSEMBLY SERIAL NO. NOTES: FROM...

-

Page 34: Vacuum Shoe Assembly

VACUUM SHOE ASSEMBLY CADET 86038220 03/16/07... - Page 35 SCR, 1/4-20 X 1 FHCS PLTD SPACER, 3/8ODX.058WX.2814,CRS VAC SHOE, 15" WASHER, 1/4 ID X 5/8 OD SS WASHER, WAVE 3/8ID X3/4D X.125 GASKET, ACCESSORY PORT SPRING, EXT .38D X2.75L X.055W CADET 86038220 03/16/07 VACUUM SHOE ASSEMBLY SERIAL NO. NOTES: FROM 5-10...

-

Page 36: Control Panel Assembly

CONTROL PANEL ASSEMBLY SEE SOLUTION TANK 5-11 CADET 86038220 03/16/07... - Page 37 BOOT, 3/8 CIRCUIT BREAKER CORD ASM, 14/3 X 22" YLW NUT, 1/2 NPT CONDUIT NUT, 6-32 W/STAR WASHER PLTD PANEL, CADET CONTROL SCR, 10-32 X 1/2 PPHMS BLK NP SCR, 6-32 X 1.0 PH BLK NYLON SWITCH, DPDT 3-POSITION ROCKER...

-

Page 38: Solution Tank Assembly

SOLUTION TANK ASSEMBLY SEE FRAME SEE FRAME 5-13 CADET 86038220 03/16/07 SEE CONTROL PANEL SEE PUMP ASM... - Page 39 GASKET, TANK, L-F GASKET, TANK, L-R GASKET, TANK, RH SCR, #10 X 1.0 PPHST TYPE B GASKET, CDT PANEL TANK ASM, SOLUTION CDT7 CORD, 99807 1/8 X 12" CARD, INSTRUCTION CDT7 CLAMP, CABLE 1/2 ID 1/4BLT CADET 86038220 03/16/07 SOLUTION TANK ASSEMBLY SERIAL NO.

-

Page 40: Recovery Tank Assembly

RECOVERY TANK ASSEMBLY 5-15 CADET 86038220 03/16/07... - Page 41 SCR, #10 X 3/4 PPHST TYPE B TANK, CDT RECOVERY BRKT, HOSE HOOK BRKT, RECOVERY HOSE MTG CORD, 99807 1/8 X 12" LABEL, WARNING LABEL, CADET MAIN DOME ASM, CLP FAM CADET 86038220 03/16/07 RECOVERY TANK ASSEMBLY SERIAL NO. NOTES:...

-

Page 42: Suggested Spare Parts/Notes

86003630 34351 FLOAT, SHUT-OFF 86003330 28061 DOME ASM, CLP FAM 86006240 66227 PLUG, DRAIN HOSE 86135340 14258 BRUSH SET, 120V 5.7 VAC, AMETEK 86135320 140687 BRUSH SET, 120V VAC, WINDSOR 5-17 1000166663 1000166663 CADET 86038220 03/16/07 SERIAL # NOTES: FROM...

Need help?

Do you have a question about the CDT7 and is the answer not in the manual?

Questions and answers