Table of Contents

Summary of Contents for BSP CG Series

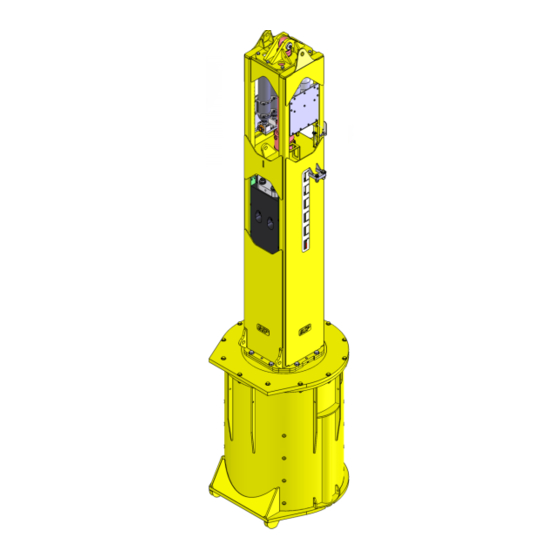

- Page 1 OPERATING MANUAL MODEL CG Range Piling Hammer BSP International Foundations Ltd. Claydon Industrial Park Great Blakenham, Ipswich, Suffolk IP6 0NL, United Kingdom www.bsp-if.com Tel. +44 (0)1473 830431 Fax. +44(0) 1473 832019...

- Page 2 CG Range SERIAL NUMBER ___________________________ OWNER ___________________________ ADDRESS ___________________________ ___________________________ ___________________________ ___________________________ When ordering spare parts please include the following information: Assembly Number Serial Number Part Description Part Number Quantity Required Order Number Issue Manual Ref. No. 4421 1999 Date Revision No.

- Page 3 Operating Manual GENERAL SAFETY Foreword Safety at Work Noise Data Limitations of use SPECIFICATIONS Hydraulic Circuit Hydraulic Supply Operating / storage temperature limits Options / Weight data Hammer lifting points OPERATING INSTRUCTIONS Connecting Controls Control Panel Layout Before commencing driving Single-Blow Operation Tamping Automatic Operation...

-

Page 4: Workshop Manual

Workshop Manual GENERAL MAINTENANCE Accumulator Pre-Charging Accumulator Servicing Assembling Cylinder into Cage Dropweight to Cylinder Connection Assembling Dropweight Torque Settings Electrical Sensor Installation FAULT DIAGNOSIS Hammer Will Not Start Hammer Will Not Run On AUTOMATIC Hammer Stops During Running No System Pressure No Pilot Pressure Slow Blow Rate Erratic Stroke... -

Page 5: General Safety

We strongly recommend that this publication be read and understood by all staff concerned before the hammer is operated in the field. BSP products are engineered for reliable operation and long life in normal conditions of use; reliability and life can be extended by careful and regular maintenance following the recommendations in the maintenance section of this manual. -

Page 6: Noise Data

3 minutes the rate reaches 25 blows per 25mm (inch) the hammer must be stopped immediately. iii. Maximum rake – when used with established BSP raking configurations 1 : 3 (18°) PLEASE NOTE: NEVER START THE HAMMER UNTIL THE HAMMER ROPE IS SLACK. THE ROPE MUST REMAIN SLACK DURING ALL DRIVING OPERATIONS, or IF A SLEDGE IS USED IT IS ALWAYS KEPT IN CONTACTWITH THE HAMMER USING THE PULL DOWN WINCH. -

Page 7: Specifications

2. SPECIFICATIONS 2.1 Hydraulic Circuit: The CG range can be operated from a BSP 250 or 260 Hydropack To cause the hammer to run: Activate the ‘System Load Valve’ (SLV) to supply oil to the hammer, and charge up the HP accumulators. -

Page 8: Hydraulic Supply

2.2 Hydraulic Supply: The flow and pressures required to operate each hammer in the CG range at rated energy and blow rate are as follows: The hammers’ will work at lower flow at reduced energy and blow rate. Model Ram Weight Operating Flow Minimum... - Page 9 2.4 Options / Weight Data The CG Hammer can be configured to operate suspended from a crane or mounted to a leader. A pile sleeve with revolving flat cap for use on larger diameter marine tubular piles can be fitted. “L”...

- Page 10 “L” (M) Option Drawing No Mass (kg) 12,291 12 Tonne Dropweight Assembly 4421 1110 1.17 16 Tonne Dropweight Assembly 4421 1005 1.50 16,441 2,900 2 Tonne Extension Kit 4421 1585 4 Tonne Extension Kit 4421 1515 4,916 Page 10 4421 1999 REV -...

- Page 11 Option Drawing No Mass (kg) Pile Guide Assembly (C/W Drive cap and sleeve to 4421 1305 14,425 suit 2M ø Piles) Pile Guide Assembly (C/W Drive cap and sleeve to 4421 1461 5,600 suit 900mm ø Piles) Helmet Retainer & Damper Housing Assembly 4421 1045 1,091...

- Page 12 Option Drawing No Mass (kg) Lifting Tackle Assembly 4421 1281 Actuator 4421 2005 CG180 Hammer Cage 4421 1584 4041 CG240 Hammer Cage 4421 1415 4287 Page 12 4421 1999 REV -...

- Page 13 2.5 Hammer lifting points Lifting points for handling hammer for transit Lifting points for 3 leg Sling / chain for Horizontal lifting 2 Pad Eye 1 Pad Eye 80ø x 30 Wide 70ø x 40 Wide Alternative lifting points for handling hammer – vertical operation Lifting points for Attach 2 Vertical lift only...

- Page 14 3. OPERATING INSTRUCTIONS 3.1 Connecting Controls Page 14 4421 1999 REV -...

-

Page 15: Control Panel Layout

3.2 Control Panel Layout The diagram below shows the control panel layout and the connecting leads to the hydraulics, guide frame and hammer. HIGH RESTART RESTART IMPACT CABLE BREAK CUT-OUT SK 7 Control Device Function 5 A Fuse Protection on input power supply Toggle Switch Main panel on/off switch 0.4 A Fuse... - Page 16 3.3 Before commencing driving Whenever the hammer is up righted for piling, it is essential that the dolly assembly is correctly positioned in the drive cap recess If the hammer is operated with the impact plate or dolly out of position, this will cause damage to the ram, drive cap and cage This check can be carried out in either of 2 ways Using the CUT OUT indicator lamp on the control panel...

- Page 17 3.4 Single-Blow Operation - (MANUAL) With the control panel switched on both power supply and o/p to sensor lights will come on. Turn control switch MANUAL TAMP to ‘MANUAL’ and AUTO 12/24v D.C. flow to 50% HIGH RESTART O/P TO SENSORS SYSTEM LOAD...

- Page 18 3.5 Tamping Operation: For small automatic blows used to input low energy in the ground. MANUAL TAMP AUTO 12/24v D.C. HIGH RESTART O/P TO Turn the control switch SENSORS to ‘TAMP’ SYSTEM LOAD VALVE OSCILLATE (NO LEAD) HAMMER CONTROL HAMMER CONTROL VALVE 12/24v D.C.

-

Page 19: Automatic Operation

3.6 AUTOmatic Operation: MANUAL TAMP AUTO 12/24v Turn control switch to ‘AUTO’. D.C. HIGH Set ‘Stroke’ to 40% ‘Dwell’ to RESTART O/P TO SENSORS minimum and Flow to 50% SYSTEM MIN. MIN. MIN. MAX. MAX. MAX. LOAD VALVE REMOTE STROKE DWELL PUMP FLOW MANUAL... - Page 20 Automatic Continued . SYSTEM SYSTEM SYSTEM SYSTEM SYSTEM LOAD LOAD LOAD LOAD LOAD VALVE VALVE VALVE VALVE VALVE HAMMER HAMMER HAMMER HAMMER HAMMER CONTROL CONTROL CONTROL CONTROL CONTROL VALVE VALVE VALVE VALVE VALVE The hammer will continue to run automatically. START LIFT OVER-TRAVEL...

- Page 21 3.7 HIGH Restart – AUTOmatic Operation: This mode is the same as ‘AUTO’ except a sensor higher up in the cage is used to trigger each stroke. This has the effect of pulling the cage down onto the pile prior to the weight lifting and giving a better transfer of energy.

- Page 22 High Restart Continued ... OVER-TRAVEL e] The ‘Stroke’ control varies STROKE the powered portion of the lift and should be altered with the flow to MIN. MAX. give the best blow rate. STROKE f] The ‘Dwell’ control varies the delay between the ‘High Restart’...

- Page 23 3.8 Stroke-Watch Operation: ( Energy Monitor) The ‘Stroke-Watch’ device has been designed to measure the impact energy delivered by the dropweight. The impact velocity is measured by two sensors in the cage termed ‘Restart’ and ‘Impact’. It plugs into the hammer control panel SK.7 and gives the operator and output of both ‘Energy’ and ‘Equivalent Stroke’...

-

Page 24: Regular Maintenance

REGULAR MAINTENANCE 4.1 Transport Whenever the hammer is configured for transport from site to site, the ram must be secured to the cage to prevent unintentional movement. An eyebolt must be screwed into the ram through a hole in the side of the cage. Provision is made for this on either side of the hammer to suit the mounting configuration. - Page 25 4.3 Hydraulic Contamination It is important that no dirt or debris finds its way into the hydraulic system. In the short term the operation of the hammer is unlikely to be effected, but the gland seals will quickly become damaged causing leakage and damage to the piston rod.

- Page 26 The oil should be warmed to at least 5°C prior to hammer operation to prevent cold oil bypassing the return filter b) If circumstances allow, the oil in the BSP HP125 should be warmed to 20°C by circulating oil over the relief valve at 50% flow.

-

Page 27: Regular Maintenance Schedule

4.5 Regular Maintenance Schedule The following checks are a guide to the frequency with which the machine should be inspected when in regular use. If it has been standing idle for some time all points need to be checked out before re-com- mencing work. - Page 28 4.6 Dolly Selection & Replacement Selection of Cushion Material BSP recommends the use of a Cast Nylon material which has been specifically processed suitable for piling use. To protect the pile from damage during driving the combination of Elastic Modulus and assembly thick- ness should not result in a stiffness of greater than 3.4 MN / mm.

-

Page 29: Vibration Damper

4.7 Vibration Damper A polyurethane damper is retained in the cage bottom adapter to absorb the recoil from the pile and prevent damage to the hammer. The damper should be replaced if it becomes miss-shapen or burns out due to overheating. To access the damper remove the hammer by removing the M48 bolts securing the hammer to the cage bottom adapter. - Page 30 Page 1 4421 1999 REV -...

Need help?

Do you have a question about the CG Series and is the answer not in the manual?

Questions and answers