Table of Contents

Advertisement

11-05

BH20030, Rev 0

DOING OUR BEST TO PROVIDE YOU THE BEST

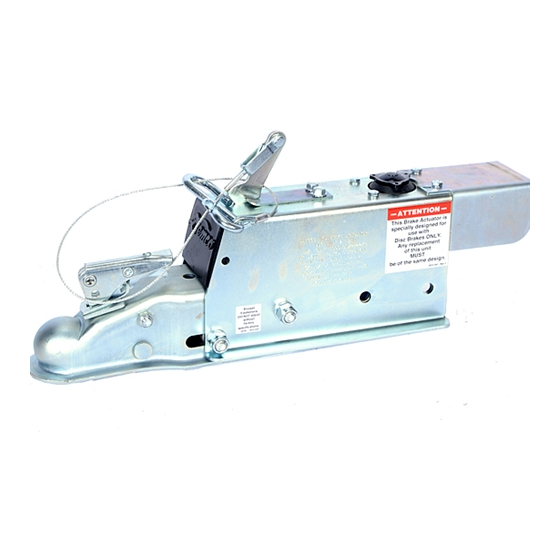

DA66B

BRAKE ACTUATOR

OPERATORS MANUAL

READ complete manual CAREFULLY

ASSEMBLY

CALIBRATION

BEFORE attempting operation.

OPERATION

REPLACEMENT PARTS

DEMCO

• Dethmers Mfg. Co. • 4010 320th St. • P.O. Box 189 • Boyden, IA 51234

•

•

PH: (712) 725-2311

Toll Free: 1-800-543-3626

FAX: 1-800-845-6420

www.demco-products.com

Page 1

Advertisement

Table of Contents

Summary of Contents for Demco DA66B

- Page 1 11-05 BH20030, Rev 0 DOING OUR BEST TO PROVIDE YOU THE BEST DA66B BRAKE ACTUATOR OPERATORS MANUAL READ complete manual CAREFULLY ASSEMBLY CALIBRATION BEFORE attempting operation. OPERATION REPLACEMENT PARTS DEMCO • Dethmers Mfg. Co. • 4010 320th St. • P.O. Box 189 • Boyden, IA 51234 •...

-

Page 2: Table Of Contents

DEMCO MODEL DA66B ACTUATOR Model DA66B is a hydraulic surge brake actuator for trailers with two or four wheels. When brakes are applied on the towing vehicle, forward inertia of trailer toward towing vehicle applies brakes on trailer in direct relation to manner brakes are applied on towing vehicle. -

Page 3: Warranty Registration

Please list the specific source of information prompting this purchase. After purchasing this product, do you see any needed product improvement? If yes, what improvement? What other products would you like to see DEMCO offer? Comments Owner’s Name: Mailing Address:... - Page 4 Postage Dethmers Manufacturing Company 4010 320th Street, Box 189 Boyden, Iowa 51234 Page 4...

-

Page 5: Safety, Signal Words

If you have questions not answered in this manual, require additional copies, or if your manual is damaged, please contact your dealer or Dethmers Mfg. Co., P .O. Box 189, 4010 320th Street, Boyden, IA 51234 ph: (712) 725-2311 or (712) 725-2302 Toll Free: 1-800-543-3626 Fax: (712) 725-2380 http://www.demco-products.com Page 5... -

Page 6: Equipment Safety Guidelines

SAFETY...YOU CAN LIVE WITH IT EQUIPMENT SAFETY GUIDELINES Every year many accidents occur which could have been avoided by a few seconds of thought and a more careful approach to handling equipment. You the operator, can avoid many accidents by observing and following precautions in this section. To avoid personal injury, study the following precautions and insist those working with you, or you yourself, follow them. -

Page 7: Safety Sign Locations

SAFETY SIGN LOCATIONS Types of safety sign and locations on equipment are shown in illustration below. Good safety requires that you familiarize yourself with various safety signs, type of warning, and area or particular function related to that area, that requires your SAFETY AWARENESS. DRUM BRAKES This decal is located in the Preset... -

Page 8: Safety Sign Care

SAFETY SIGN CARE • Keep safety signs clean and legible at all times. • Replace safety signs that are missing or have become illegible. • Replacement parts that displayed a safety sign should also display safety sign. • Safety signs are available from your distributor, dealer parts department, or factory. How to install safety signs: •... -

Page 9: Before Operation

BEFORE OPERATION: • Carefully review and follow the installation instructions on page 16 of this manual. • Carefully study and understand this manual. • Always wear protective clothing and substantial shoes. • Give equipment a visual inspection for any loose bolts, worn parts, or cracked welds, and make necessary repairs. - Page 10 • Beware of bystanders, PARTICULARLY CHILDREN! Always look around to make sure it is safe to start engine of towing vehicle or move equipment. This is particularly important with higher noise levels, as you may not hear people shouting. • NO PASSENGERS ALLOWED- Do not carry passengers anywhere on or in equipment. •...

-

Page 11: Following Operation

FOLLOWING OPERATION • Following operation, or when unhitching, stop towing vehicle, set brakes, shut off the engine and remove ignition key. • Store unit in an area away from human activity. • Do not permit children to play on or around stored unit. •... -

Page 12: Performing Maintenance

• Watch for obstructions overhead and side to side while transporting. • Always operate equipment in a position to provide maximum visibility at all times. Make allowances for increased length and weight of equipment when making turns and/or stopping. PERFORMING MAINTENANCE Carefully review and follow the maintenance instructions on page 17 of this manual. -

Page 13: Bolt Torque

BOLT TORQUE TORQUE DATA FOR STANDARD NUTS, BOLTS, AND CAPSCREWS. Tighten all bolts to torques specified in chart unless otherwise noted. Check tightness of bolts periodically, using bolt chart as guide. Replace hardware with same grade bolt. NOTE: Unless otherwise specified, high-strength Grade 5 hex bolts are used throughout assembly of equipment. -

Page 14: Da66B Brake Actuator Parts Breakdown And Parts List

8605001 DRUM BRAKE ACTUATOR PARTS Do not tighten these bolts. They are factory torqued and must remain loose enough to allow free coupler movement. ACTUATOR PARTS LIST REF. PART NO. QTY. DESCRIPTION 12190-95 6000# 2" Lever Lock Coupler SB23278 Roller 12151 Front Roller Spacer 02166... - Page 15 8605101 DISC BRAKE ACTUATOR PARTS Do not tighten these bolts. They are factory torqued and must remain loose enough to allow free coupler movement. 2 8 3 0 ACTUATOR PARTS LIST REF. PART NO. QTY. DESCRIPTION 12190-95 6000# 2" Lever Lock Coupler SB23278 Roller 12151...

-

Page 16: Actuator Installation And Maintenance

To avoid personal injury or death, do not exceed lowest of (1) the rated capacity of Model DA66B actuator, or (2) rated capacity of ball and hitch being used, or (3) trailer's Gross Vehicle Weight Rating (GVWR). Model DA66B brake actuator has a maximum load rating of 6000 lbs. - Page 17 5. Once bleeding is completed, refill master cylinder to within 1/2” of top. and attach cap (#18) securely. Replace emergency lever spring, lever guide, lock washers and 5/16" hex head bolts. Wipe up any excess brake fluid immediately to prevent paint damage. 6.

-

Page 18: Demco Brake Products Limited Warranty

Demco warrants system to be free from defects in materials and workmanship for two years when properly installed, used, and maintained by purchaser. Any part of Demco brake system found to be defective in materials or workmanship will be repaired or replaced at manufacturers option without charge for parts or labor to original owner. -

Page 19: Demco Brake Products Limited Warranty Cont

2) road film or gravel damage to paint. 3) paint. 4) rust damage. 5) any Demco brake product that has been loaded in excess of load capacity stated on identification label. 6) Accessory parts, materials or components. Warrantor has a policy of continuous product improvement. We reserve the right to change or improve design of any Demco brake product, including but not limited to state of the art changes, without assuming any obligation to modify any product previously manufactured.Warrantor... - Page 20 DETHMERS MFG. COMPANY P.O. BOX 189 4010 320th St., BOYDEN, IA. 51234 PH: (712) 725-2311 FAX: (712) 725-2380 TOLL FREE: 1-800-54DEMCO (1-800-543-3626) www.demco-products.com Page 20...

Need help?

Do you have a question about the DA66B and is the answer not in the manual?

Questions and answers