Table of Contents

Advertisement

INSTALLATION OPERATION and MAINTENANCE MANUAL

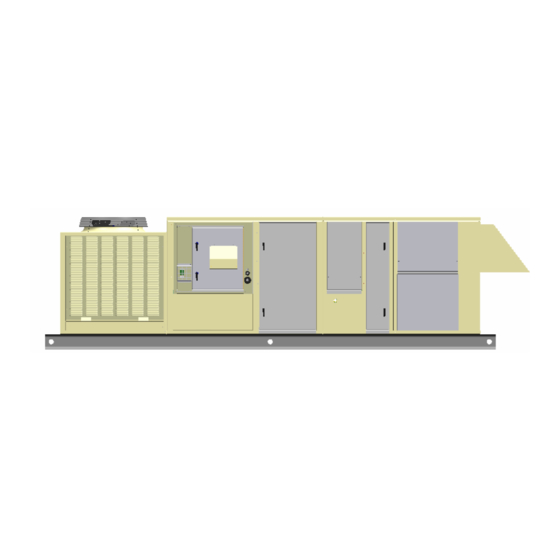

High Efficiency Packaged Models DC Series B, Air Conditioning

Safety Labeling and Signal Words...........2

General Description ..................................3

Unpacking, Inspection ........................3

Design Certification..............................3

Codes & Ordinances ............................3

Installation..............................................3- 6

Unit Location, Clearances ...................3

Curb Installation ...................................3

Rigging...................................................4

Electrical ................................................4

Ductwork ...............................................5

Condensate Piping ...............................5

Gas Piping and Venting ...................5- 6

Cooling System Options .......................6- 8

Hot Gas Bypass ....................................6

Head Pressure Control.........................6

Variable Speed Control ........................6

Hot Water Heat Recovery.................7, 8

Mechanical Adjustments ....................9, 10

Evaporator Blower Fan ..................9, 10

Electrical System Options ......................10

Air Flow Switch...................................10

!

WARNING: READ SAFE OPERATION RULES AND MANUAL CAREFULLY

1

Systems, Model Sizes 036 Thru 420

No Heat Recovery Cabinet

Extended Heat Recovery Cabinet

TABLE OF CONTENTS

Clogged Filter Indicator ..........................10

Convenience Outlet ............................10

Exhaust Fan Interlock ........................10

Power Through the Curb ...................10

Firestat.................................................10

TM

Sure-Trip

..........................................10

DDC controls.......................................10

Sequence of Operation ...........................11

Heating, Steam/Hydronic ...................11

Gas Heat ..............................................11

Electric Heat ........................................11

Energy Conservation Wheel..............12

Trouble Shooting Guides...................13-18

General Refrigeration Circuit .......13-16

Varispeed™ Condenser Control .......15

Hot Gas Bypass Regulator ................16

Gas Furnace ........................................17

R410A

Advertisement

Table of Contents

Need help?

Do you have a question about the DC Series and is the answer not in the manual?

Questions and answers

What is the approximate weight of a DC 360 unit?