Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for EMD EXP-103

- Page 1 PALLET STRETCH WRAPPING MACHINE MODEL: EXP-103 OPERATION MANUAL...

-

Page 2: Table Of Contents

TABLE OF CONTENT GENERAL INFORMATION .................. 3 NOTE OF INSTALLATION ..................3 NOTICE OF OPERATION ..................4 SPECIFICATION ....................5 SPEC. TABLE ......................5 MACHINE DIMENSION ..................6 MACHINE DESCRIPTION ..................7 OPERATION DESCRIPTION ....... Error! Bookmark not defined.8 INSTALLMENT ...................... 8 REMINDER OF INSTALLATION ................ -

Page 3: General Information

1. GENERAL INFORMATION NOTE OF INSTALLATION To make sure a safe and correct operation, please check below conditions before install the machine: 1) Power source capacity must be equal of the machine need. 2) Machine standard power is 110v/220v (+- 10%) 3) Machine standard power Hertz is 50/60 Hz. -

Page 4: Notice Of Operation

NOTICE OF OPERATION To have good protection for the operator, please make sure the following conditions: 1) Before operating, please read the machine operational manual carefully. 2) Make sure there is no object put on the power cable. 3) Make sure there is no object put on the upper elevator unit. 4) Avoid any damp object or water around the electric parts. -

Page 5: Specification

2. SPECIFICATION SPEC. TABLE Model EXP-103 Turntable Speed 3 ~ 12 RPM Turntable dia. 1500mm Max wrapping height 2200mm Pallet size 1050x1050mm Max loading weight 2000kgs 300% & 230% two step change by handle Film stretch (%) (250% and 200% option) Adjustable –... -

Page 6: Machine Dimension

MACHINE DIMENSION... -

Page 7: Machine Description

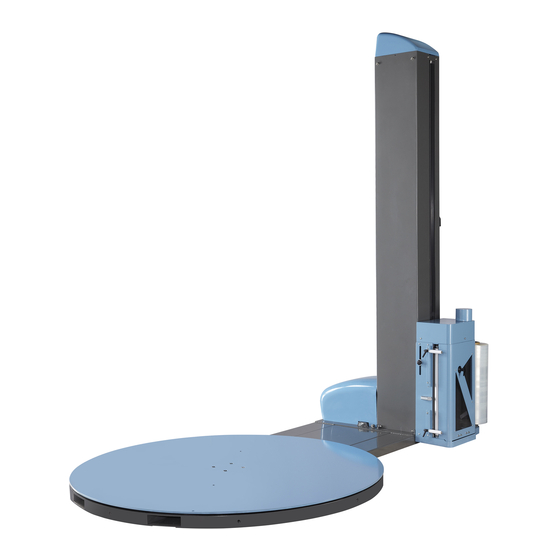

MACHINE DESCRIPTION TOWER CONTROL BOX MOTOR COVER CARRIAGE TURNTABLE SEAT... -

Page 8: Operation Description

OPERATION DESCRIPTION INSTALLMENT 1) Apart all the wooden package. Avoid damaging the machine. 2) Move the machine to an installment position by fork lift. 3) Install master cover and tighten screws on both side. 4) Lift up the tower. 5) Fix and tighten the tower by M8 screws. Total 6 screws on each side. 6) Connect the sensor wires. -

Page 9: Reminder Of Installation

REMINDER OF INSTALLATION Tower Installation Engineers must ensure all screws are properly installed underneath the tower, and evenly lay out. Control Panel Installation Engineers must make sure the control panel is removed from supporting bracket, and is installed properly. -

Page 10: Operation Of Control Panel

OPERATION OF CONTROL PANEL... -

Page 11: Operation Description

OPERATION DESCRIPTION Top Sheet Up & Down Film Force Up Only Top wraps During Cycle Bottom Wraps Turntable Speed Carriage Speed Top Wraps Adj. Up or Down Film Enforce - Btm Wraps Adj. No. of wraps. Height from. Manual Carriage Manual Turntable Up or Down Key Lock... - Page 12 START BUTTON Press this button to start operation. Note: After all of function been setting press this button to re start the program PAUSE BUTTON Press the button; the machine will be stop whether it is under automatic or manual mode. Press the START button to complete the rest program. EMG.

-

Page 13: Carriage Unit

CARRIAGE UNIT 1) Illustration for film threading 1. OPEN THE SECURITY DOOR FIRST. 2. Pull the film across the film carriage. 3. CLOSE THE SECURITY DOOR SECURITY DOOR FILM FILM Cling Outside Cling Inside... -

Page 14: Electrical

4. ELECTRICAL ELECTRICAL CAPACITY 1 ) Power Consumption Pre-stretch motor 0.2 KW Turntable motor 0.75 KW Elevator Motor 0.4KW Control & wiring box DC 24V 50W Machine Power Use 1.5 KW Power Socket need 1.7 KW 1.25 ㎜ 2) Power Cable ---------------------- 3) Machine input -------------------- 110V / 230V 1-PHASE... -

Page 15: Electrical Diagram

ELECTRICAL DIAGRAM Sensor / limit switch location... - Page 16 4B10 3S9B 3S9C PART NO DESCRIPTION Q'TY KEY NO 3S9B P0311-060001400 LIMIT SWITCH ML-7312 3S9C P0311-060001400 LIMIT SWITCH ML-7312 P0311-060001100 LIMIT SWITCH TZ-8108 P0311-060001100 LIMIT SWITCH TZ-8108 P0302-020000200 PHOTO SENSOR A3R-2MX P0311-060001210 LIMIT SWITCH TZ-8108 4B10 P0302-010001600 PROX SWITCH XS4-P18-AB110 P0301-0000300 SOLENOID SH-1585 (DC24V)

- Page 22 ELECTRIC PARTS LIST FOR EXP-103 PART NO DESCRIPTION Q'TY KEY NO P0305-010001200 POWER FUSE (IK60N2PC16A) 1Q2A P0311-010002800 POWER SWITCH (ZH-HD-48-BY) P0307-010000400 POWER 24Vdc (DR-4524 24Vdc-2A) PER-STRETCH INVERTER 73050215 INVERTER, ATV12H037M2, 220V 73050218 INVERTER, ATV12H037F1 1/2HP, 110V TURNTABLE INVERTER 73050216 INVERTER, ATV12H075M2 1HP, 220V...

-

Page 29: Trouble Shooting

5. TROUBLE SHOOTING GENERAL ADJUSTMENT 1) Turntable belt adjust Please see the illustration 5-1, and then loosen the motor seat M10 screw 4 pcs. Turn the (M10) on the seat until get enough tension. Turn and tight the motor seat screw 4 pcs again. -

Page 30: Trouble Shooting With Exp-108 Machine

TROUBLE SHOOTING WITH EXP-103 MACHINE Machine trouble Cause Description Solution X8=OFF 1.EMG BUTTON Exam if EMG Switch is locked. Release X9=ON 2.CONTROL BOX POWER switch. CUT SWITCH Check if EMG Switch is faulty. Check if Control box Power Cut switch is faulty. -

Page 31: Part List

PART LIST SEAT... - Page 32 SEAT PART LIST FOR EXP-103 KEY NO PART NO DESCRIPTION Q'TY P01-000081A TURNTABLE 1.5M P01-000080A TURNTABLE 1.65M P0311-060001200 LIMIT SWITCH VL-8108 P02-0050100 SENSOR PLATE P0703-0001900 PULLEY P1104-026205ZZ0 BEARING 6205ZZ(CWB) P02-0050000 BEARING SEAT P0902-0007300 BELT BX-140 P0902-0007400 BELT BX-144 P01-045120A TURNTABLE BASE 1.5M P01-044540A TURNTABLE BASE 1.65M...

-

Page 33: Tower

TOWER... - Page 34 TOWER PART LIST FOR EXP-103 KEY NO PART NO DESCRIPTION Q'TY P01-0451800 MASTER COVER GEAR REDUCER MOTROR, 1/2HP, P0503-0008500 3-PH, 220V/380V P01-044580A MOTOR BASE SEAT P06-004850A BELT TURNING SHAFT P02-028960A BELT TURNTING SHAFT P02-0277600 SHAFT SLEVE P02-0278800 PULLEY PLATE P02-0279000...

- Page 35 TOWER PART LIST FOR EXP-103 KEY NO PART NO DESCRIPTION Q'TY P06-0047300 SLIDING BLOCK P02-0289800 BELT FIXING SHAFT P02-0289900 HOOK FIXING SHAFT P01-0453100 SLIDING CART P1201-0008500 SPRING P01-0446600 ANTI-FAILING HOOK P02-0292400 BUSHING...

-

Page 36: Carriage

CARRIAGE... - Page 37 CARRIAGE PART LIST FOR EXP-103 KEY NO PART NO DESCRIPTION Q'TY P01-0449400 TENSION ADJUSTMENT COVER P06-0049500 TENSION INDICATOR PLATE P06-0049000 PLATE BRACKET CARRIAGE FRAME – COVER P01-0449300 CARRIAGE FRAME – COVER BASE P01-0448200 GEAR REDUCER MOTOR 1/4HP, P0501-0002800 3-PH, 220V/380V...

- Page 38 CARRIAGE PART LIST FOR EXP-103 KEY NO PART NO DESCRIPTION Q'TY P02-0291100 PIN PUNCH P0301-0000300 SOLENOID SH-1585 DC24V) P02-0289400 SAFETY PEDAL ROTATING SHAFT P0311-060001400 LIMIT SWITCH ML-7312 P01-0006700 HOLDING PLATE P1110-020000500 HINGE CL-208-3 P02-0003300 P01-044900A CARRIAGE SAFETY PEADL P02-0004200 BEARING SEAT...

- Page 39 EXP-103 CARRIAGE PART LIST FOR KEY NO PART NO DESCRIPTION Q'TY P06-0005300 GEAR PULL WHEEL P0701-0007400 SPROCKET 37T P0701-0007500 SPROCKET 34T P02-0291400 SPROCKET SHAFT P01-0447000 PRE-STRETCH SENSOR BLOCK P02-029200A SENSOR BLOCK SHAFT P02-0005000 DANCING BAR SHAFT P1202-0010300 DANCING BAR SPRING...

Need help?

Do you have a question about the EXP-103 and is the answer not in the manual?

Questions and answers