Summary of Contents for Nihon Bisoh BISOMAC210

- Page 1 BISOMAC210 Specifications for North America 3P model Electric Traction Hoist Operator’s Manual [with Overload Detection Device] NIHON BISOH CO., LTD.

- Page 2 + Keep this manual with the hoist at all time. + Use only spare parts and steel wire rope recommended by NIHON BISOH. + Use only machinery or incorporated component, which MUST COMPLY with UL1323, CAN/CSA Z271-10 and national, regional, or local implementing.

-

Page 3: Table Of Contents

2.3 BISOLOAD ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 14 2.4 Wire Ropeꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 14 2.5 Power Cable ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 15 3. FUNCTION AND DESCRIPTION OF EACH COMPONENT ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 16 3.1 BISOMAC210 TRACTION HOIST ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 16 3.2 BISOLOCK ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 19 3.3 BISOLOAD ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 20 4. WORK ENVIRIONMENT ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 21 5. - Page 4 7. DAILY TESTS AND INSPECTIONS ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 37 7.1 Tests and inspections: Rigging materials ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 37 7.2 Tests and inspections: Wire rope ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 38 7.2.1 Shape and size of wire rope ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 38 7.2.2 Shape and size of the end of wire rope ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ 39 7.3 Tests and inspections: Hoist ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ...

-

Page 5: Read Before Use

Temperature Range: between 14 ゚F (-10 ℃) and 104 ゚F (+40 ℃). Humidity: Less than 100 % (without inundation, condensation and freezing) Protection Grade: IP54 Maximum Wind Speed: In accordance with the specifications of platform. Altitude: 3280ft (1,000m) or lower Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... - Page 6 If the load on the platform is light, descent speed of emergency controlled descent may be slower. k) The main suspension wire rope must be vertically set and installed to the hoist. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

- Page 7 [Installation of the hoist 1] Suspension wire rope Suspension wire ☓ ☓ ✔ Correct Installation NOT vertically suspended [Installation of the hoist 2] ✔ ☓ NOT vertically suspended Correct Installation Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

- Page 8 Do not use the hoist as a traction device which pull horizontally. h) Do not use the hoist as a medical traction device. i) Do not use the hoist in potentially explosive atmosphere. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

-

Page 9: For Safe Use

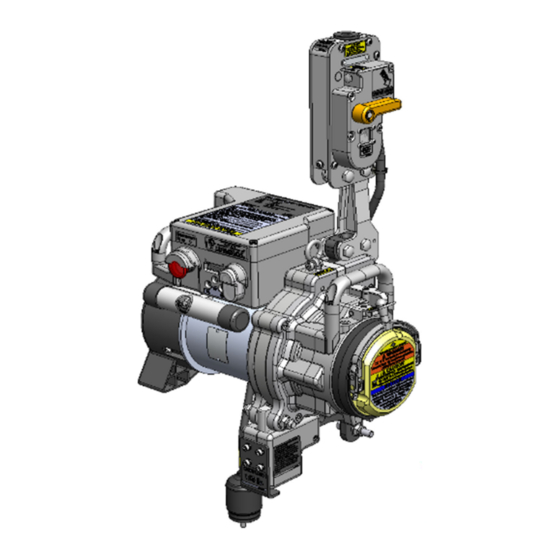

This Operator’s Manual is written for operators to use the equipment safely and properly. Electric Traction Hoist manufactured by NIHON BISOH Co., Ltd. BISOMAC210 Electric Traction Hoist 3P model (referred to as the hoist) is consists of Hoisting Device (referred to as BISOMAC), Fall Arrest Device (referred to as BISOLOCK) and Overload Detection Device (referred to as BISOLOAD). -

Page 10: Maintenance

Safety instructions attached to the hoist and safety devices [BISOMAC Front side] Description Meaning and Location ●Instruction of Emergency controlled descent 1. Emergency Control Descent & ●Instruction of Electromagnetic Brake ●Warning of skin burn Electromagnetic Brake Caution [Electromagnetic Brake] Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... - Page 11 ●QR code to access Operator’s manual on 4. Specification and Operation website [Control Box Cover] [BISOMAC Back side] Description Meaning and Location ●Instruction to the operator 5. Restriction Use [Control Box Cover] Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

- Page 12 [Control Box Cover] ●Instruction of Operator’s Manual 8. Operator’s Manual [Operator’s Manual Storage] ●Instruction of BISOLOAD(OL) and Different 9. Lamp Phase Detection (RP) [Control Box] ●Instruction of Voltage 10. Power Voltage [Fan Cover] Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

- Page 13 ●Specifications of Gear Box 11. Gear 210 [Gear Box] ●Instruction of connecting plug of safety 12. Plug mark device [Control Box] ●Instruction of connecting plug of remote 13. Plug connection control pendant switch [Control Box] Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

- Page 14 ●Instruction of activation lamp 3. Overspeed Indicator&Reset ●Instruction of Release Lever [Governor Cover] ●Instruction of activation of the device 4. Instruction of Overspeed Detection ●Instruction of spec and operation of the Device device [Side Plate] Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

- Page 15 [BISOLOCK Left and Upper side] Description Meaning and Location ●Instruction of wire rope 5. Wire Rope Diameter [Side Cover 1] ●Instruction of Trip Button 6. Instruction of Manual Trip Button [Governor Cover] Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

- Page 16 [Limit Switch Cover LA] BISOLOAD Left and Right side] Description Meaning and Location ●Instruction of rated load 2. Rated Load [Guard] ●Instruction of wire rope outlet 3. Wire Rope Exit [Rope Cover] Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

-

Page 17: Specifications

Use Environment Pressure Atmospheric pressure 1 year or 100 operating hours since last maintenance. NOTE: It depends on the actual condition of use at work sites. (Refer Maintenance Cycle to “4. WORK ENVIRONMENTS”. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 18: Bisolock

45.0 kN Load (5253 kg) (4520 kg) (4540 kg) (4131 kg) (4590 kg) Finish Galvanized Galvanized Galvanized Galvanized Galvanized ・BISOMAC210-3P1000 Applicable ・BISOMAC210-3P1150 Model ・BISOMAC210-3P1258U ・BISOMAC210-3P1508U NOTE Designated wire ropes by NIHON BISOH Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 19: Power Cable

Type SOOW Core and Size 3P: 4 cores, 10AWG minimum Rated Voltage 600V Length 500 ft(152 m) or shorter per a platform Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 20: Function And Description Of Each Component

3.FUNCTION AND DESCRIPTION OF EACH COMPONENT 3.1 BISOMAC210 TRACTION HOIST BISOLOCK BISOMAC BISOLOAD Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... - Page 21 Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

- Page 22 Lights up when reverse phase is detected. *only 3P Overload Indicator Lamp Lights up when BISOLOAD is activated. Cable Guard Protection plate for cable and connector. Pendant Control Socket Remote control pendant switch can be connected. OP *Optional Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

-

Page 23: Bisolock

BISOLOCK. Governor Inspection Window to check the rotation of governor. Window Trip Button Switch to activate BISOLOCK manually. Lights up if DOWN button is pressed when BISOLOCK is Activation Indicator Lamp activated. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 24: Bisoload

Bolts for fixing BISOLOAD to the hoist. Bolt B B Stirrup Fixing Bolt Bolts for fixing BISOMAC to the platform. C Guide Roller Guide roller to support the load of wire rope (tail line). Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 25: Work Envirionment

Oil in the gear box may be cured. This may cause BISOMAC to start hardly. After work, necessary preventive measure not to freeze moistures in the hoist must be taken. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 26: Set Up Instructions

Voltage supplied to the hoist should not exceed the rated voltage range (refer to Section 2.1). Otherwise motor may get overheated, result in malfunction or injury of operator. Rated voltage range (±10%) is only temporarily acceptable. It does not mean continuously acceptable voltage range. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... - Page 27 Do not touch the wire rope while the hoist is operating. There is a risk of fingers or the entire hand being pulled in with the wire rope. This may result in serious injury. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

-

Page 28: Step 1 Installation Of Safety Devices To Bisomac

●M12 Plain washer x4 ●M12 Nylon nut x4 BISOLOCK Mounting Bracket BISOMAC [Provided by NIHON BISOH] ●BISOLOAD mounting bolt B x2 ●M12 Plain washer x4 ●M12 Nylon nut x4 Electromagnetic Brake BISOLOAD [Picture-2] Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... - Page 29 Tightening torque: 76 N・m (770 kgf・cm) 4. Connect the cables of BISOLOCK and BISOLOAD to BISOMAC. (See Picture-3) Cable of BISOLOCK Cable of BISOLOAD Connector of BISOLOCK Connector of BISOLOAD [Picture-3] Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

-

Page 30: Step 2 Connecting To Power Supply

1. Connect the power cable of BISOMAC to power supply from central control box. Please check the types of connector. Type Manufacturer HUBBELL HBL2423 Cover the socket with appropriate cover shown below. Type Manufacturer HUBBELL HBL6032 Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... - Page 31 ・The hoist operates normally when UP/DOWN button is pressed. 4. Ensure that current capacity and size of circuit breaker is adequate. (Refer to section 2) 5. Ensure that connectors are not cracked or damaged. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

-

Page 32: Step 3 Installation Of Suspension Wire Rope

4. Distances between riggings and wire rope inlet of the hoist must be equal as suspension wire ropes are suspended vertically. 5. To prevent the platform from running off the suspension wire ropes, secure the tail line as Picture-5. Suspension wire rope Clamp Tail line [Picture-5] Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 33: Step 4 Installation Of The Hoist

BISOMAC mounting bolt x2 M12 Plain washer x4 M12 Nylon nut x2 Outside of the platform Stirrup Tail line [Picture-6] STEP 5 Perform daily inspection Perform daily inspection according to section 7. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 34: Operating The Hoist

Storing with unstable state cause the hoist to fall down. It may cause injury or damage to the hoist. NOTE: Do not stack BISOMAC more than 2 steps. Otherwise BISOMAC may fall down and be damaged. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... - Page 35 Electric leakage due to inundation may cause malfunction or unintentional move. It may cause platform to fall or tilt and consequently operators or objects might fall, resulting in serious injury or death to operators or passers-by. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

- Page 36 NOTE: Do not use the hoist if Emergency controlled descent lever does not work properly. Otherwise, in the event of power loss, the platform may not be able to descend and operator cannot escape. Such hoist must be repaired and retested before using. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

-

Page 37: Carrying The Hoist

Press UP button to UP travel. ・ Press DOWN button to DOWN travel. ・ If Emergency stop button is pressed, power is cut off. The hoist shall not run in either ・ direction. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 38: Emergency Controlled Descent Lever

If Emergency controlled descent lever is broken, refer to Maintenance Procedure Manual (separately issued). Fixing Bolt Lever Stopper Emergency Controlled Descent Lever [Picture-7] Emergency Controlled Descent Lever [Picture-8] Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 39: Releasing Procedure Of Bisolock

1. Operate UP travel to reeve wire rope approximately 2 inch. 2. Pull down Release Lever and deactivate BISOLOCK. (See Picture-9) 3. Confirm that activation indicator lamp is unlit. (See Picture-9) Release Lever Activation indicator lamp [Picture-9] Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... - Page 40 6. Confirm that activation indicator lamp does not light up when DOWN button is pressed. NOTE: If BISOLOCK is not activated and the platform continue falling, press Trip Button to manually activate BISOLOCK. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

-

Page 41: Daily Tests And Inspections

Inspect all rigging materials which support load of the equipment (such as nut, bolt, clamp, wire clip, shackle, and so on) and wire ropes. Ensure that they are not damaged or worn down and that they are secured properly. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 42: Tests And Inspections: Wire Rope

4. Average diameter of 3/8 inch wire rope becomes φ0.374 in. (9.5 mm) or more 5. Heavily rusted and found pitting on surface. 6. Wire rope that has been exposed to temperature above 200℉. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 43: Shape And Size Of The End Of Wire Rope

Within 0.197 in. (5 mm) Within 0.394 in. (10 mm) Radius of top end [R] R0.118 in. (3 mm) R0.157 in. (4 mm) ●The end of wire rope shall be shaped as below. [Photo-2] Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 44: Tests And Inspections: Hoist

・Ensure that the hoist is properly installed to the platform. ・Ensure that central control box is connected to power supply. ・Check circuit breaker and ensure that power is not cut off. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 45: Lifting The Platform And Emergency Stop Function

4. Confirm that red indicator lamp of the Emergency Stop Switch lights up. 5. Ensure that the hoist does not operate even operation switch is operated. 6. Reset Emergency stop switch. Ensure that the hoist resumes its normal operation. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 46: Controlled Descent Function

4. Pull Emergency controlled descent lever gently and lower the platform. 5. Check if the platform descends at a slow, controlled speed. NOTE: If the platform descends with increasing speed, release hand from the lever immediately and contact local distributor. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 47: Bisolock

8. Confirm that UP/DOWN operation is operable. Also confirm that Governor is rotating while the platform is ascending/descending. Apply same procedure to another BISOLOCK. NOTE: If BISOLOCK does not hold wire rope properly, contact local distributor to replace Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 48: Periodic Maintenance

Otherwise, the hoist may malfunction or unable to operate normally. This may cause the platform to fall or tilt and consequently operators or objects might fall, resulting in serious injury or death to operators or passers-by. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... -

Page 49: Troubleshooting At Job Site

3. Insufficient voltage. 3. Check Voltage meter if sufficient voltage is 4. Power cable is too long or too small. supplied. 4. Replace power cable to shorter or thicker one. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4... - Page 50 4. Defect inside the hoist or the devices. 5. Check and tighten each bolt and nut. 5. Loosened bolts and nuts. 6. Replace with designated wire rope.(2.3) 6. Improper wire rope is used. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

- Page 51 (1) Operate UP travel approx. 2 inch. (2) Pull down Release Lever. (3) Reset competed. *DO NOT forcibly reset BISOLOCK. Pin inside Release Lever may be broken and become unable to reset. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

- Page 52 4. Added cautions Revision 4: November 30, 2020 1. Corrected errors 2. Added restriction 3. Added thermal protector, BISOLOCK and BISOLOAD to the safety devices 4. Added use environment 5. Revised structure of sentences Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

- Page 53 November 30, 2020 Revision 4 “NIHON BISOH CO., LTD.”, “BVE", “BVE Building Value Engineering”, “BISOMAC” are registered trademarks of NIHON BISOH CO., LTD. All copy rights and patents by NIHON BISOH CO., LTD. Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4...

Need help?

Do you have a question about the BISOMAC210 and is the answer not in the manual?

Questions and answers