Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for PBI Barocycler 2320EXT

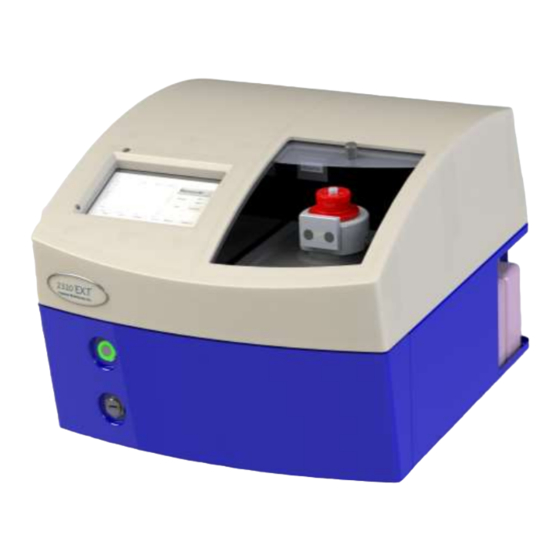

- Page 1 Barocycler 2320EXT Pressure Cycling Technology (PCT) Sample Preparation System Operator’s Manual Operator’s Manual Version: 2.4, June. 2017 Pressure BioSciences, Inc. 14 Norfolk Ave. South Easton, MA 02375 508-230-1828 www.pressurebiosciences.com Page 1 of 32...

- Page 2 6,696,019; 6,753,169; European Patent Numbers EP 814900; EP 924991; EP1112091, Australian Patent AU 745925; additional patents pending. Use of the Barocycler 2320EXT Pressure Cycling Technology Sample Preparation System conveys no patent rights, expressly or by implication, under any patent or patent application owned by Pressure BioSciences, Inc., that covers the Pressure Cycling Technology Sample Preparation System, any composition, reagent or...

- Page 3 There are no user serviceable parts inside the Barocycler 2320EXT housing. No user access is permitted beyond the sliding door of the instrument. Do not attempt to open or disassemble the unit. Any service beyond routine maintenance has to be performed by the manufacturer or other authorized service facilities.

-

Page 4: Table Of Contents

INSTALLATION AND OPERATION Powering up the System Preheat the Barozyme Chamber Loading the Sample Carrier and Chamber Shutdown and Emergency Stopping Barocycler 2320EXT Software Main Screen and Sub-menus Advanced Features of the 2320EXT Software User Management, GLP/GMP and Electronic Records Compliance. Maintenance... -

Page 5: General Information

General Information Warning Symbols Notes, cautions and warnings are used to highlight certain operating procedures and recommendations. A note indicates a special procedure, an exception to normal operation, or something else of specific interest to the reader. The following symbols describe the warning and cautions used in the operation of this instrument. This symbol on the instrument indicates that the user should refer to the operating manual before attempting to connect the power/interface cables and operate the instrument. -

Page 6: Overview And Theory Of Operation

PCT MicroTubes, or one sample at a time in PCT PULSE Tubes. The Barocycler 2320EXT is capable of generating pressure up to 45,000 psi (45 kpsi). The instrument’s intensifier amplifies air pressure to generate high hydrostatic (water) pressure. The air-water intensifier has an amplification ratio of 450:1. - Page 7 Please contact your local distributor or PBI Customer Service to learn more about the features and limitations of either configuration and to arrange a conversion, if desired.

-

Page 8: Installation And Operation

A PBI field engineer or your local distributor will supply an appropriate AC power cord to match your local electrical code requirements during the initial installation visit. Make sure the unit is plugged in to an appropriate power outlet. -

Page 9: Preheat The Barozyme Chamber

NOTE: Only PCT MicroTubes or PCT PULSE Tubes from Pressure BioSciences should be used in the Barocycler 2320EXT. Use of unapproved sample containers may result in tubes breaking and/or leaking under pressure. In addition, fragments of broken sample containers may enter the fluid lines and cause malfunction of the check valves that would require instrument disassembly and service. - Page 10 Load samples into MicroTubes as described in MicroTube Product Insert. Close MicroTubes using either PCT MicroPestles (for tissue homogenization) or PCT MicroCaps. o For homogenization with PCT MicroPestle, place up to 3mg of solid tissue per MicroTube. Add 30µl lysis reagent, and cap with a MicroPestle.

- Page 11 (C:\Users\USERNAME\My Documents). Previously saved parameters can be loaded using the Load button. All parameter files have the extension .pbi, although parameter files are instrument mode-specific. For instance, loading a parameter file saved in Barocycler mode will change the instrument mode to Barocycler and load the selected parameters into its Settings.

- Page 12 During the pressure run the Run key will become the Pause key and the Stop key will no longer be grayed out. When the Run stops, The Pause key will once again become the Run key and the Stop key will be grayed out.

-

Page 13: Shutdown And Emergency Stopping

® WARNING: THIS INSTRUMENT IS CONTROLLED BY A MICROSOFT WINDOWS COMPUTER. AVOID POWERING DOWN THE INSTRUMENT BEFORE SHUTTING DOWN WINDOWS TO AVOID POSSIBILITY OF FILE CORRUPTION! Barocycler 2320EXT software 3.1 Main Screen and Sub-menus Main Screen Page 13 of 32... - Page 14 The Main Screen consists of the following controls and displays: Operating Mode Selector (blue arrow): Select Barocycler Mode, Waveform Mode or Ramp Mode. Pressure: Displays the current pressure in the chamber. Temperature: Displays the current temperature in the chamber. ...

- Page 15 o Manual – For manual control of the pressure intensifier, see Advanced Features of the 2320EXT Software (section 3.2). The Settings screen is used to set the pressure run parameters such as the pressure level, number of cycles, temperature, etc. The Settings sub-menu is dynamically changed depending on the instrument Mode selected.

- Page 16 o Graph: Graphical editor offers an ability to draw the pressure profile on the touch screen. Inflection points can be placed on the graph by tapping the screen at appropriate places. Software will interpret the coordinates of the taps approximately. If more accuracy is desired, values for each point in the graph can be edited using the Table feature accessible via the button in the top right corner of the graph.

- Page 17 Waveform Mode Settings: In Waveform mode the pressure profile can be set to oscillate around an offset value. The amplitude and period of the oscillation can be controlled (as long as the maximum pressure does not exceed 45kpsi). Unlike Barocycler mode, in Waveform mode the pressure in the chamber does not have to drop to ambient between cycles.

-

Page 18: Advanced Features Of The 2320Ext Software

Administrator privilege. Basic users can only change their own password by clicking on Modify Users. NOTE: Make sure DAC is enabled on the Services tab – this feature facilitated communication between the software and the instrument control circuits. The use of this feature is reserved for the PBI service personnel. - Page 19 in any way. However, the Sense Temperature feature, if enabled, would abort the run when chamber temperature deviates outside of the configured acceptable range. Make sure that the circulator bath is turned on and calibrated to maintain the temperature of the Barocycler pressure chamber within a desired temperature range, if automatic monitoring of chamber temperature is enabled.

- Page 20 Please contact PBI support if you believe that the chamber temperature reading is inaccurate and needs to be adjusted. PBI offers a temperature calibration as part of the IQ/OQ procedure and a periodic re-calibration service, if desired.

-

Page 21: User Management, Glp/Gmp And Electronic Records Compliance

Windows file system. PBI recommends that users save run log archives onto regularly backed-up network drives were they could be labeled as read-only to protect them from accidental or intentional deletion. Moreover, conventional Windows 7 Embedded Standard user-level security can be enabled in the operating system by your local network administrator, providing additional layer of security. - Page 22 PDF Run Report and into a raw data file (if storage of raw data is enabled as described above). Note that only PBI field service technician or an authorized PBI distributor will have access to the configuration options. Please request whether this option should be enabled for you when purchasing your new Barocycler 2320EXT system, or contact your local service representative if you desire to change the LIMS setting in your existing instrument.

-

Page 23: Maintenance

Maintenance The 2320EXT is designed to require only a minimum amount of maintenance to keep the system in optimum operating condition. WARNING: Only authorized persons should service the electrical and pressure generating components of the instrument. Improper service may lead to system damage and could cause personal injury. General Maintenance The following maintenance should be performed as indicated. - Page 24 Table 3. Periodic 2320EXT calibration and maintenance Schedule for cGxP environment* Task Weekly Monthly Annually Inspect the System Log for critical errors Inspect the remaining hard disk storage and perform data backup. Inspect Windows Embedded Standard Event Logs for critical errors Check and correct MS Windows Date/Time settings Run MS Windows Update routine, if system is not connected to...

-

Page 25: Confirm Quality Of Compressed Air

Several extra O-rings are provided in the 2320EXT accessories kit. Additional O-rings can be purchased from PBI (cat# UC-90144). Step 5. Apply a small amount of O-ring lubricant (provided in 2320EXT accessories kit) to the new rubber O- ring. -

Page 26: Cleaning And Reassembly Of Chamber Closure Valve

O-ring (see instructions above). If water continues to flow from this tubing, there is an issue with the Closure Check Valve. Clean check valve (see below). If this does not solve the problem, call PBI. To clean the closure check valve and reassemble the closure: Step 1. -

Page 27: Contacting Pbi Support

Contacting PBI support. To reach PBI Technical Support by email, send your questions to: TechnicalSupport@pressurebiosciences.com Or you can call us at: (508) 230-1828 (select option 2). You can also visit our website at pressurebiosciences.com. Click on Contact Us at the top of the page. Please provide your name, contact information and question(s). -

Page 28: Troubleshooting Guide

Service screen. “The 2320EXT was not detected. acquisition hardware. If that does not fix the problem, call PBI Support. Please ensure the USB cable is connected and try again.” Close the door by sliding it all the way toward the front of the... -

Page 29: Hardware Troubleshooting

Contact PBI Customer support. Make sure the air compressor is on. Make sure there is at least No air output from The unit fails to start when the Run 110psi in the compressor tank. -

Page 30: Sample Container Troubleshooting

Contact PBI support if this happens. The red tubing is connected to the intensifier seal. Leakage of fluid from the red tubing indicates an intensifier seal leak. Contact PBI support if fluid is leaking from the red tubing. 5.3 Sample Container Troubleshooting... -

Page 31: Appendix A: Installation Requirements

Appendix A: Installation Requirements: Space Requirements: The Barocycler can be placed on a bench or a laboratory cart. Height 36.8 cm (14.5 inches) Width 48.2 cm (19.0 inches) Depth 54.6 cm (21.5 inches) Weight 34 kg (75 pounds). For ventilation and access to fill/waste bottles an additional 5 inches of space is required at the rear and sides of the Barocycler. -

Page 32: Appendix B: Warranty

PBI as warranty or otherwise. PBI shall not be liable to the extent allowed by local law for loss, expense, or damage to customer or third party, for incidental or consequential damages. The obligation of PBI under this Warranty shall be to repair or replace the product, as set herein.

Need help?

Do you have a question about the Barocycler 2320EXT and is the answer not in the manual?

Questions and answers