Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Affetti Pumps CGV-N

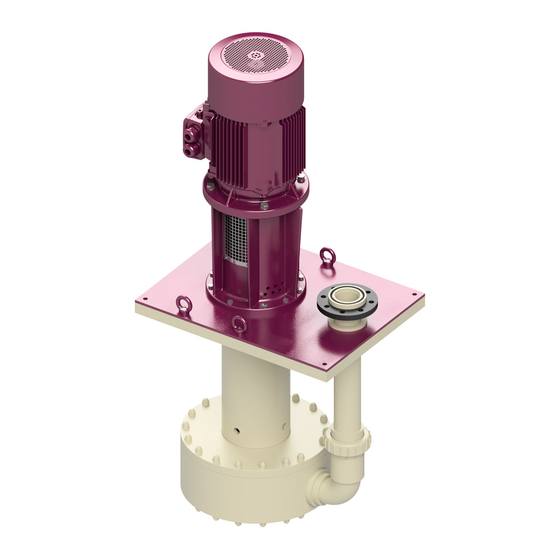

- Page 1 MANUAL OF INSTRUCTIONS FOR THE INSTALLATION, THE USE, THE MAINTENANCE AND THE SAFETY OF THE VERTICAL ELECTRIC PUMPS CGV-N AFFETTI Via Maroncelli n.4 – 21053 Castellanza (Va) – Italia Tel. +39 0331 503358-505595 – Fax. +39 0331 483007 E-mail: affetti@affetti.com - Web-site: www.affetti.com...

-

Page 2: Table Of Contents

CGV-N INDEX GENERAL INFORMATION pag. 3 EXECUTION ” “ PUMP BODY ” “ IMPELLER ” “ ROTOR ” “ REAR BLOCK ” “ INTERMEDIATE ADAPTOR ” “ SUPPORT PLATE…………………………………………………………………………………………………………………………… pag. 4 MARKING ” “ GUARANTEE AND CERTIFICATION ” “ PRE - INSTALLATION pag. -

Page 3: General Information

ROTOR On the CGV-N series the rotor is driven and held by means of grease-Iubricated ball bearings. The connection between the shaft and the motor is established by means of an elastic joint. -

Page 4: Support Plate

CGV-N SUPPORT PLATE The support plate is entirely manufactured of a technopolymer and assures a perfect stability and a solid anchorage of the pump to the vat or to the tank. If necessary, on request or in special cases, it can be equipped with a metallic counter-plate to reach a higher compactness. -

Page 5: Pre - Installation Pag

CGV-N PRE - INSTALLATION PACKING The structure of the packing and the employed materials are chosen according to shape, dimensions and weight of the machine, which has to be shipped. We may adopt solutions of the following type: cardboard box with filling material for machines of small dimensions ;... -

Page 6: Installation

CGV-N INSTALLATION POSITIONING OF THE MACHINE The pump has to be mounted vertically and in the best possible position to assure an easy connection with the delivery tube. The machine should be positioned in immediate neighbourhood of the vat or tank so that a rapid intervention is guaranteed in case of preventive maintenance or damage. - Page 7 CGV-N indicate when the water has reached the maximum or minimum height that is necessary to cover the pump body and the eventual intermediate flanges and keep it from overflowing the vat or the tank. If the machine includes an external flow line with an electro-valve, the cleaning and the lubrication of the guide sleeves of the shaft is guaranteed by the total insulation of its tract.

-

Page 8: Connection Of The Electric Motor

CGV-N CONNECTION OF THE ELECTRIC MOTOR We advise to follow with care the schemes of the motor producer, which you can find in the terminal box or in the instruction manual. Recommended Safety Measures It is highly dangerous to start the pump before having completed the installation. The assembly operations have to be performed by specialized and trained staff. -

Page 9: Operation

CGV-N OPERATION START OF THE PUMP Before starting the pump you should take the following steps: a) Please make sure that the delivery tube is correctly connected and that the bolts are well tightened. b) Please check if in the vat there is the liquid, which has to be pumped, and that its level is at least high enough to cover the whole body of the pump. -

Page 10: Capacity Range

CGV-N CAPACITY RANGE The choice of the type of pump, impeller and motor takes place at the moment of ordering by taking into the consideration the capacity and head data requested by the customer. The user should carefully observe the operating conditions mentioned on the data sheet and especially the data regarding capacity and head at the operating point to which the machine has been destined. -

Page 11: Hints On Correct Operation

CGV-N HINTS ON CORRECT OPERATION PREVENTIVE MAINTENANCE The performances of the pump depend on the number of working hours, the materials used for its construction and on the care with which the pump is treated during its operative life. A daily check during operation helps to avoid complications and assures an immediate intervention in case of damage. -

Page 12: Eventual Dry Functioning Of The Pump

CGV-N Recommended Safety Measures To operate in conditions of extreme safety during the control of the running machine the operator should be adequately equipped. Rubber gloves and boots, anti-acid overalls and helmet with protective visor for the face are the indispensable equipment for the persons who have to operate without running the risk of physical damages. -

Page 13: Troubles And Eventual Causes

CGV-N TROUBLES AND EVENTUAL CAUSES THE PUMP DOES NOT EROGATE ANY LIQUID In the vat there is no liquid. The no-return valve on the suction tube is blocked and totally closed. The impeller is blocked by rubbish or incrostations contained in the liquid. -

Page 14: The Guide Bushes Of The Shaft Get Rapidly Worn Out

CGV-N THE GUIDE BUSHES OF THE SHAFT GET RAPIDLY WORN OUT 28) The flowing liquid or the pumped liquid contains foreign bodies or abrasive substances or the flow duct is obstructed. 29) The gaskets or other employed materials are not suitable for the characteristics of the pumped liquid. -

Page 15: Cross Sections Pag

CGV-N 19 20 18 48 34... - Page 16 CGV-N...

- Page 17 CGV-N...

- Page 18 CGV-N 89 86...

- Page 19 CGV-N 89 86 87 85 88 15...

-

Page 20: Part List

CGV-N PART LIST POS. DESCRIPTION POS. DESCRIPTION Motor O-Ring Screw Screw Plate Seal Ring Covered Nut Support Flange Column Greaser Shaft Ball Bearing Shaft covering Ball Bearing Covered Nut Seal Ring O-Ring Ring Nut O-Ring Coupling Rear Block Washer O-Ring... -

Page 21: Maintenance And Repair Operations

CGV-N MAINTENANCE AND REPAIR OPERATIONS REMOVAL FROM THE PLANT Before disconnecting the pump from the plant please take the following steps : a) Make sure that the pump is not running. b) Detach the plug from the electric switchboard. c) Detach the electric cables from the terminal board and carefully isolate the ends. - Page 22 CGV-N following operations: a) disassemble the lower segment of the column by unscrewing the nuts (pos. 70) which join the two parts. b) Extract the protective covering (pos. 8) of the shaft together with the rotating bush (pos. 69). c) Disassemble the intermediate support (pos. 65).

-

Page 23: Assembly Procedure Of The Pump

CGV-N PROCEDURE FOR PUMP ASSEMBLY Having disassembled the pump and decided which parts need replacing, clean thoroughly all the parts which are still in good condition with water or an appropriate solvent. Original spare parts must be used to replace parts in a bad condition. -

Page 24: Recommended Spare Parts

CGV-N Useful indications The assembly and disassembly operations of the pump can be performed exclusively by persons who have got basic mechanical knowledge and skills. For a better understanding of the characteristic features sufficient notions on the materials, which are used for the construction of the machine, are indispensable.

Need help?

Do you have a question about the CGV-N and is the answer not in the manual?

Questions and answers