Table of Contents

Advertisement

Quick Links

Th e Right Fit for Comfort

ECR International Inc

2201 Dwyer Avenue

Utica, NY 13501

e-mail: info@RetroAire.com

An ISO 9001-2008 Certified Company

Packaged Terminal Air Conditioner (PTAC)

Packaged Terminal Heat Pump (PTHP)

™

9,000

2.6

9,000

2.6

Installation, Operation,

& Maintenance Manual

R30C / H

Straight cooling nominal capacities

12,000

15,000

3.5

4.4

Heat pump nominal capacities

12,000

15,000

3.5

4.4

R30C | R30H

Replacement for:

ZoneAire & Keeprite C/CHP series,

and Carrier 51P/PH series

packaged terminal units.

Btuh

kW

Btuh

kW

P/N 240008641, Rev. B [8/31/2010]

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Retro Aire R30C

- Page 1 R30C / H Packaged Terminal Air Conditioner (PTAC) Packaged Terminal Heat Pump (PTHP) ™ Straight cooling nominal capacities 9,000 12,000 15,000 Btuh Th e Right Fit for Comfort Heat pump nominal capacities 9,000 12,000 15,000 Btuh Installation, Operation, & Maintenance Manual...

-

Page 2: Table Of Contents

Seasonal start-up and maintenance..19-20 R30C/R30H Chassis ....5 Heat pump units — temporary emergency heating mode . 20 PTAC/PTHP Model Coding Troubleshooting sensors . -

Page 3: Inspection

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Read This First (continued) General precautions Recognize this symbol as an indication DANGER of important safety information. Electrical Supply Carefully read the rating plate located on the front panel. Th e RetroAire replacement PTAC/PTHP must: Inspection Be properly connected... -

Page 4: General Product Information

• Installation, Operation, and Maintenance Manual • General Product Information Controls Product description • Unit-mounted operating controls include thermostat, fan speed control, RetroAire Replacement Packaged Terminal Air Condition/Heat heat/cool switch, fan cycle switch, fresh air switch (if equipped) Pumps units are available in straight cooling (PTAC) or as heat pump •... -

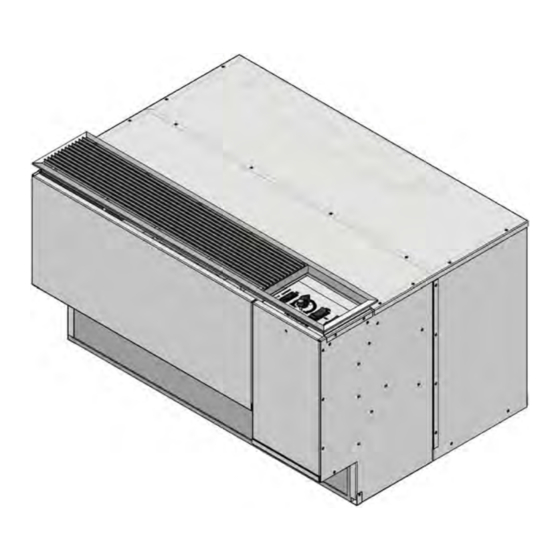

Page 5: R30C/R30H Chassis

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • General Product Information (continued) Figure 1 R30C | R0H chassis Fresh Air Switch (FAS) System Speed Switch Switch (SS) (FSS) Thermostat High Pressure Switch (HPS) Hydronic... -

Page 6: Ptac/Pthp Model Coding

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • PTAC/PTHP Model Coding Figure 2 Model coding Position number: Chassis coding [verify with rating plate] Product Series Compressor Codes R_ _C - Straight Cool Unit - 30 = TECH R_ _H - Heat Pump Unit -30 = LG... -

Page 7: Features

• Installation, Operation, and Maintenance Manual • Features Indoor coil freeze protection Anti-short cycle timer (standard) (standard) Th is feature will prevent the indoor coil from freeze up in the cooling Th e microprocessor control uses this timing to prevent short-cycling mode. -

Page 8: Optional Wall-Mounted Thermostats

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Features Motorized fresh air damper Selecting a thermostat (by others) (optional) When selecting a thermostat other than one off ered by EMI, choose Th e optional motorized fresh air damper allows fresh air into the space to be conditioned. -

Page 9: Preparing For The Installation Of The Ptac/Pthp

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Preparing for the Installation of the PTAC/PTHP WARNING Electrical powe r connection Moving parts can cause personal injury. Avoid contact with Check the RetroAire unit rating plate for circuit ampacity and moving parts when testing or servicing the unit. -

Page 10: Installation Instructions - R30C | R30H

• Installation, Operation, and Maintenance Manual • Installation Instructions — R30C | R30H Installation Verify the existing wall thickness — Th e distance from the condenser coil to the outdoor louver varies with sleeve depth, Installation kit contents unit(s) ship standard with 1 3∕8 "(35mm) & 1 1∕2”(38mm) baffl es. -

Page 11: Sequence Of Operation

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Sequence of Operation Trouble The following Sequence of Operation Code Status applies to PTAC/PTHP units. (Blinks) Th e R_ _C units are straight cool, single stage air conditioners avail- Normal Operation able with electric or hydronic heat. - Page 12 Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Sequence of Operation (continued) NOTE: with auxiliary heat will continue until the outdoor coil sensor reaches 50 ºF (10 ºC). • Remote-Mount Cooling Operation depends on the features of the wall-mounted thermostat.

-

Page 13: Final Inspection & Start-Up

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Final Inspection & Start-up CAUTION Before operating the unit Any obstruction of supply air, including the use of defl ector baffl es, may cause condensate to form on the louver or cabinet ☐... -

Page 14: Setting The Control Board Jumpers

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Final Inspection & Start-up (continued) NOTICE Figure 7 TEST jumper (selects normal or test mode) All wiring should be in accordance with both the National Test mode Normal operation Electric Code (NEC) and the local building codes. -

Page 15: Start Up

• Installation, Operation, and Maintenance Manual • Final Inspection & Start-up (continued) Figure 9 Typical Representation of a Unit Mount Control Start Up Ensure the unit is secure and level. Heat pump units only — Verify that the thermostatic drain pan valve is operating correctly. -

Page 16: Heat Pump Pthp's

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Final Inspection & Start-up (continued) thermostat or system switch in the HEAT position. Place the NOTICE Adjust the thermostat to a warmer temperature. Th e room temperature must be above 65°F (18°C) for the Th e following should then occur: compressor to operate in cooling mode on PTAC's with unit- •... - Page 17 Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Final Inspection & Start-up (continued) starts running. Th e compressor and outdoor fan should then turn on NOTICE and cold air will begin to fl ow from the unit. Let the unit continue operating to cool the room and remove humidity.

- Page 18 Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Final Inspection & Start-up (continued) and turn on the indoor fan. NOTICE If a cooler room temperature is desired, adjust the thermostat to Room temperature must be below 85°F(29°C) to energize the a cooler temperature sett ing.

-

Page 19: Maintenance & Troubleshooting

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Maintenance & Troubleshooting Figure 10 Manual Reset Limit Switch Monthly inspection and maintenance Reset Button DANGER Electrical shock hazard — disconnect power to the *Note: RetroAire replacement PTAC/PTHP before servicing or ac- Button will pop cessing the control compartment. -

Page 20: Heat Pump Units - Temporary Emergency Heating Mode

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Maintenance & Troubleshooting (continued) Look for oil leaks or stains on or around all braze joints and refrig- sensor from the circuit board. A 2-stage thermostat will provide erant lines. -

Page 21: Troubleshooting

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Maintenance & Troubleshooting (continued) Troubleshooting WARNING Th e troubleshooting procedures below should only be conducted by a qualifi ed technician. Symptom Suggestion No heat or cooling •... -

Page 22: Performance Data

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Performance Data Table 2 R30 C/H performance data Model Cooling Sensible Heat Pump COP Indoor Air Shipping Heat Flow Weight Ratio Btuh (kW) Btuh (kW) CFM (L/s) lbs (Kg) R 30 C 09 9,000 (2.6) -

Page 23: Electrical Specifi Cations

Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Electrical Specifi cations IMPORTANT Due to ongoing product development, designs, specifi cations, and performance are subject to change without notice. Please consult the factory for further information. R30 C/H - 9,000 BTU Table 3 electrical specifi... - Page 24 Electrical Specifi cations IMPORTANT Due to ongoing product development, designs, specifi cations, and performance are subject to change without notice. Please consult the factory for further information. R30C - 15,000 BTU Table 5 electrical specifi cations Power Supply Indoor Fan...

- Page 25 Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • P/N 240008641, Rev. B [8/31/2010] Made in USA...

- Page 26 Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Notes The Right Fit for Comfort P/N 240008641, Rev. B [8/31/2010]...

- Page 27 Replacement Packaged Terminal Air-Conditioning / Heat Pump • Installation, Operation, and Maintenance Manual • Notes P/N 240008641, Rev. B [8/31/2010] Made in USA...

- Page 28 Warranty ECR International Inc 2201 Dwyer Avenue Utica, NY 13501 e-mail: info@RetroAire.com An ISO 9001-2008 Certified Company The Right Fit for Comfort P/N 240008641, Rev. B [8/31/2010]...

Need help?

Do you have a question about the R30C and is the answer not in the manual?

Questions and answers