Table of Contents

Summary of Contents for ATI Technologies AOV

- Page 1 AOV Media Changer System Product Manual Document #: 9610-50-1046 Engineered Products for Robotic Productivity Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com...

-

Page 2: Table Of Contents

Manual, AOV Media Changer System Document #9610-50-1046-02 Table of Contents Product Overview ........................3 Media Feeder ..........................3 Media Remover ..........................4 Media Checker ..........................4 Installation of Components ..................... 5 Media Feeder Installation ......................6 Media Remover Installation ......................7 Media Checker Installation ...................... -

Page 3: Product Overview

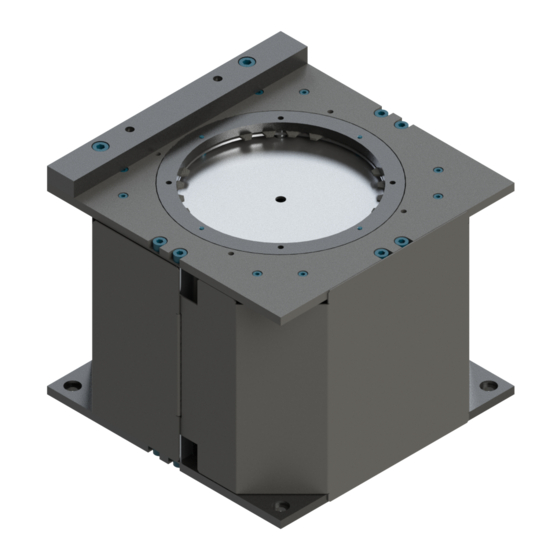

Document #9610-50-1046-02 1. Product Overview The AOV Media Changer (AMC) is an accessory to the AOV tools. The AMC works with standard industrial sanding disc and allow for adaptation to changing assembly lines and part requirements. The AMC system allows the checking and changing of media without human interaction, once a program is in place. -

Page 4: Media Remover

CAUTION: Needles can pinch or puncture clothing and skin avoid contact during setup, service, and operation of needle grippers causing injury to personnel and damage to equipment. The media remover uses pneumatically actuated needles to remove media from AOV. Figure 1.2—Media Remover (Not a Recommended Mounting Orientation) Needle Gripper... -

Page 5: Installation Of Components

Manual, AOV Media Changer System Document #9610-50-1046-02 2. Installation of Components Required Equipment: The items listed in this section are the minimum requirements to operate the AMC. 1. (2) 4 mm air lines in for media remover. Each air line will supply air to the Media Remover and operate the needle drive mechanism. -

Page 6: Media Feeder Installation

2.1 Media Feeder Installation The media feeder can be installed at any an angle and in any orientation that allows the AOV sanding pad to contact the media in the feeder completely. To install the media feeder, complete the following procedure:... -

Page 7: Media Remover Installation

Manual, AOV Media Changer System Document #9610-50-1046-02 2.2 Media Remover Installation The media remover can be installed at any an angle and in any orientation that allow the media to fall away from the media remover. Figure 2.2 is shown only for information purpose and is not a recommended mounting orientation. -

Page 8: Media Checker Installation

The media checker can be installed at any an angle and in any orientation that allow the sanding pad of the AOV to contact the piston in the checker completely. The media checker can be installed by performing the following procedure:... -

Page 9: Pneumatics

Manual, AOV Media Changer System Document #9610-50-1046-02 2.4 Pneumatics The air supply should be dry, filtered, and free of oil. A coalescing filter (ATI Part # 9005‑50‑6160 or equivalent) with elements rated for 5 micron or better is required. Customer supplied solenoid valves are actuated from the robot or program logic controller by means of a digital output signal. -

Page 10: Operation

Manual, AOV Media Changer System Document #9610-50-1046-02 3. Operation The media changer system uses (3) different components. The robot program must accommodate for any clearance needed. Refer to Section 3.1—Recommended Sequence of Operations for AMC for more details. CAUTION: Do not use spare parts other than original ATI spare parts. Use of spare parts not supplied by ATI can damage equipment and void the warranty. -

Page 11: Recommended Sequence Of Operations For Amc

3.1 Recommended Sequence of Operations for AMC 3.1.1 Recommendations 1. When teaching the motions, be sure that the AOV is positioned perpendicular to the working surfaces for each media change module. 2. Consider a method of discarding used discs removed by the Media Remover. A recommended option is to mount the Remover in a way so that the used discs will drop into a collection bin after the removal process. - Page 12 Manual, AOV Media Changer System Document #9610-50-1046-02 The closest edge of the backing pad should be ½” to 1” away from the alignment rail. Figure 3.3—Away 2 5. TOUCH: Move diagonally (from the “AWAY” position in step 4) so that the backing pad is lightly pressed against the rail, pushing the sander’s orbital position away from the rail.

- Page 13 Manual, AOV Media Changer System Document #9610-50-1046-02 7. ALIGN: Align the sander with respect to the hole with the sanding discs. Confirm that the orbit is set fully back (6 o’clock position) before saving this point. b. Reliability can be improved for fetching by tilting the sander slightly (20 degrees) toward...

- Page 14 Manual, AOV Media Changer System Document #9610-50-1046-02 9. ALIGN and DROP: Pull the pad out of the feeder and return to the “ALIGN” position from step 6. Tilt the sanding pad and repeat step 7. This step helps to ensure the disc is properly attached as well as keep the stack of new media held down for the next fetch command.

-

Page 15: Check Media

Manual, AOV Media Changer System Document #9610-50-1046-02 3.1.3 Check Media Teaching this process should be done without a sanding disc on the pad to test the hook and loop 1. Start at the HOME position. 2. ABOVE: Align the sanding pad above the Media Checker’s loop pad. - Page 16 Manual, AOV Media Changer System Document #9610-50-1046-02 3. TOUCH: Lower the sander until the backing pad makes full contact with the hook and loop. Figure 3.12—Touch 4. UP: Raise the sander until the Checker has reached its furthest extension. An audible cue (sound of the hook and loop separating) can be used to determine the furthest extension.

-

Page 17: Sand

Manual, AOV Media Changer System Document #9610-50-1046-02 3.1.4 Sand • It is important to test the removal of a freshly used disc. The friction generated from normal sanding operation can cause the hook and loop to bind stronger than a manually applied sanding disc. - Page 18 Manual, AOV Media Changer System Document #9610-50-1046-02 4. TOUCH: Move the sander to make firm contact with the top plate and extend the needles (90 PSI). It is recommended to wait up to one second before the next motion command.

-

Page 19: Normal Operation

Manual, AOV Media Changer System Document #9610-50-1046-02 6. AWAY: Using Figure 3.8 as a reference, move the sander up 12.0 inches and 9° travel to the right (approximately 1.9 inches of lateral travel). Make sure to move far enough away from the needles so that the disc is completely removed (at least the distance of one and a half disc diameters). -

Page 20: Troubleshooting And Service Procedures

Manual, AOV Media Changer System Document #9610-50-1046-02 4. Troubleshooting and Service Procedures 4.1 Troubleshooting The following section provides troubleshooting information to help diagnose conditions with the product and resolve these conditions. CAUTION: Thread locker applied to fasteners must not be used more than once. -

Page 21: Service Intervals

Manual, AOV Media Changer System Document #9610-50-1046-02 Table 4.1—Troubleshooting Symptom Possible Cause Resolution Examine the condition of the sanding The sanding pad may be pad and replace the sanding pad if worn and needs replacing. there is excessive wear. There is debris build up on... -

Page 22: Service Procedures

Manual, AOV Media Changer System Document #9610-50-1046-02 4.3 Service Procedures 4.3.1 Replacement of Retaining Gasket, Constant Force Springs, and Media Support Glides in Media Feeder Parts required: Refer to Section 5—Serviceable Parts Tools required: 2 mm, 2.5 mm, 4 mm, and 5 mm hex keys, 7/16 wrench, torque wrench Supplies required: Loctite ®... - Page 23 Manual, AOV Media Changer System Document #9610-50-1046-02 3. Disassemble the media feeder: Using a 5 mm hex key to remove the (2) M6 socket head cap screws from the alignment rail. Figure 4.2—Media Feeder (2) M6 Socket Head Cap Screw...

- Page 24 Manual, AOV Media Changer System Document #9610-50-1046-02 5. If replacing the glides: Using 4 mm hex key and 7/16 wrench to remove and a wrench to detach the spring assembly from the feed tray by removing the ¼‑20 socket head cap screw and nut.

- Page 25 Manual, AOV Media Changer System Document #9610-50-1046-02 6. If replacing the springs: Using a 2.5 mm hex key and 6 mm wrench to remove the M3 socket head cap screw and nut securing the spring assembly to the feed tray.

- Page 26 Manual, AOV Media Changer System Document #9610-50-1046-02 7. Secure the feed tray assembly to the top plate assembly by applying Loctite 222 to the (8) M3 socket head cap screws. Tighten to 12 in‑lbs (1.356 Nm) using a 4 mm hex key.

-

Page 27: Replacement Of Hook Disc On Media Checker

Manual, AOV Media Changer System Document #9610-50-1046-02 4.3.2 Replacement of Hook Disc on Media Checker Parts required: Refer to Section 5—Serviceable Parts Tools required: 2 mm hex key Supplies required: Clean rag 1. Using a 2 mm hex key to remove the M3 flat head socket cap screw. -

Page 28: Serviceable Parts

Manual, AOV Media Changer System Document #9610-50-1046-02 5. Serviceable Parts Table 5.1—Media Changer Part Number Description 3610‑0601801‑12 Compression Spring, .18 OD, .375 Lg, Music Wire, Zinc 3610‑2000001‑21 Coil Spring, Constant Force, .39 OD x 12" Lg, SS 3710‑50‑1525 Disc, Multipurpose Loop, 1‑1/8" OD 3710‑50‑1526...

Need help?

Do you have a question about the AOV and is the answer not in the manual?

Questions and answers