Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Wittenstein Alpha TP+

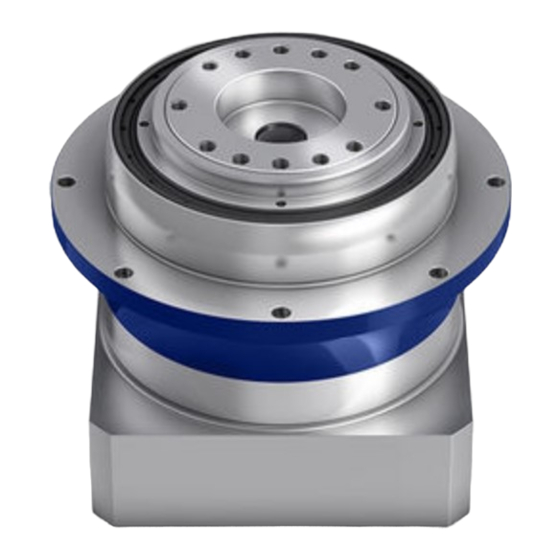

- Page 1 2022-D036009 Assembly Instructions 2022-D036009 Revision: 03...

- Page 2 Motor mounting video © WITTENSTEIN alpha GmbH 2012 This documentation is copyright protected. WITTENSTEIN alpha GmbH reserves all the rights to photo-mechanical reproduction, copying, and the distribution by special processes (such as computers, file media, data networks), even in parts.

-

Page 3: Table Of Contents

Contents Regarding this manual..................2 1.1 Information symbols .....................2 General safety instructions .................2 2.1 Identification plate ....................2 2.2 Intended use ......................2 2.3 Reasonably predictable misuse ................2 2.4 Guarantee and liability ..................2 2.5 General safety instructions ..................3 2.6 Storage ........................4 2.7 Checking the tightening torques ................4 2.8 Maintenance schedule ..................4 2.9 Malfunctions ......................4 Technical data sheets ..................5... -

Page 4: Regarding This Manual

Lubricant DMF: 05/12 Made in Germany Production date WITTENSTEIN alpha GmbH - Walter-Wittenstein-Str.1 - 97999 Igersheim Tbl-1: Identification plate (template) Intended use The gearhead serves to convert torques and speeds in industrial applications. The gearhead may not be operated in areas with explosion hazards. In food processing, the gearhead may be used only next to or under the foodstuff area. -

Page 5: General Safety Instructions

General safety instructions General safety instructions Suspended loads can fall and can cause serious injuries and even death. Only use hoisting equipment and transports with sufficient capacity. Do not stand under suspended loads. Objects flung out by rotating components can cause serious injury and death. -

Page 6: Storage

General safety instructions Solvents and lubricants can pollute soil and water. Use and dispose of cleaning solvents as well as lubricants appropriately. Storage Store the gearhead in horizontal position and dry surroundings at a temperature of 0 °C to +40 °C in the original packaging. -

Page 7: Technical Data Sheets

Technical data sheets Technical data sheets Be informed of the general safety instructions before beginning work. (see Chapter 2.5 "General safety instructions"). Transport of gearheads up to and including size TP No special transport mode is prescribed for transporting the gearhead. Transport of gearheads as of size TP For gearheads of size TP 110 or greater, we recommend the use of hoisting equipment. -

Page 8: Mounting The Gearhead To A Machine

Technical data sheets Push the motor shaft into the clamping hub of the gearhead. The motor shaft should slip in easily. If this is not the case, the clamping bolt needs to be loosened some more. A slotted bushing has to be installed extra for certain motor shaft diameters and applications. ... -

Page 9: Mounted Components On The Gear Output Side

Technical data sheets Do not use washers (e.g. plain washers, tooth lock washers). For prescribed screw sizes and torques refer to Chapter 3.10 "Specifications on mounting onto a machine", table "Tbl-9". Mounted components on the gear output side Distortions during mounting operations can damage the gearhead. -

Page 10: Details Regarding The Attachment To A Motor

Technical data sheets Details regarding the attachment to a motor Designation Clamping bolt Clamping ring (part of the clamping hub) Bushing Motorshaft Tbl-7: Arrangement of motor shaft, clamping hub, and bushing Gearhead Clamping Clamping Width Tightening torque Max. axial force size TP screw (H) across... -

Page 11: Specifications On Mounting Onto A Machine

Technical data sheets Gearhead Clamping Clamping Width Tightening torque Max. axial force size TP screw (H) across [Nm] property class clamping hub [N] interior Ø / DIN ISO flats 12.9 8.8 (alu) Plug Coupling “x” [mm] 4762 [mm] (steel) receptacle 110 1-stage x≤38 38<... -

Page 12: Specifications On Mounting On The Gear Output Side

Technical data sheets 3.11 Specifications on mounting on the gear output side Thread in output flange Gearhead size Bore Ø Quantity x Thread x Tightening torque / Design TP Depth [mm] [Nm] [ ] x [mm] x [mm] Property class 12.9 31.5 8 x M5 x 7 004 MF... -

Page 13: Performance Statistics

Technical data sheets 3.13 Performance statistics Refer to our catalogue or our Internet page for the maximum permitted speeds and torques: http://www.wittenstein-alpha.de Consult our Customer Service department if the gearhead is older than a year. You will then receive the valid performance data. 3.14 Supplementary information The complete operating manual can be found on our website:... - Page 14 2022-D016962 : 01 WITTENSTEIN alpha GmbH · Walter-Wittenstein-Straße 1 · 97999 Igersheim · Germany Tel. +49 7931 493-12900 · info@wittenstein.de WITTENSTEIN - being one with the future www.wittenstein-alpha.de Motor mounting video enAC: XXXXXXXX 2022-D016962 Revision: 01...

Need help?

Do you have a question about the TP+ and is the answer not in the manual?

Questions and answers