Advertisement

Quick Links

Air Piston & Servo Filling / Depositing Systems

Air Piston & Hydraulic Transfer Pumps

Spotters & Stripers

Icers & Glazers

Custom Integrated Designs

PACIFIC FRUIT PROCESSORS, INC.

SOUTH GATE, CA | USA

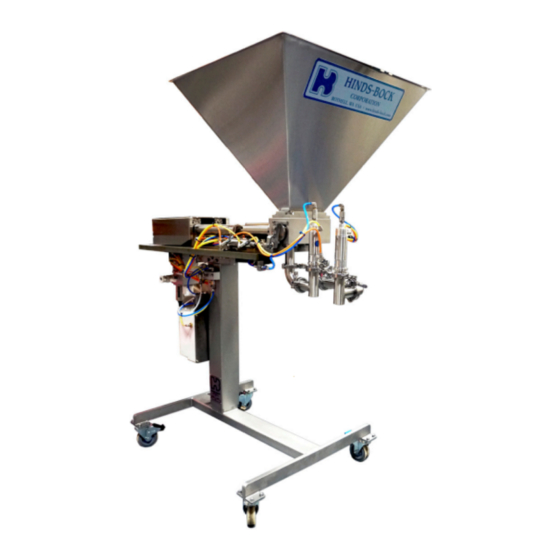

SINGLE PISTON FILLER/DEPOSITOR

MODEL No.:

SERIAL No.:

MFG. DATE:

2122 - 222

nd

TEL

425.885.1183

TEL:

877.292.5715 (MAIN – TOLL FREE)

TEL:

888.557.7881 (PARTS DEPARTMENT – TOLL FREE)

FAX:

425.885.1492 (MAIN)

FAX:

425.897.4110 (PARTS DEPARTMENT)

WEB:

www.HINDS-BOCK.com

E-MAIL:

SALES INFORMATION:

PARTS:

parts@hinds-bock.com

SP-64B

0005537

MAY 2007

Street S.E. | Bothell, WA 98021-4430 | U.S.A.

sales.inquiries@hinds-bock.com

Advertisement

Summary of Contents for Middleby Hinds-Bock SP-64B

- Page 1 Air Piston & Servo Filling / Depositing Systems Air Piston & Hydraulic Transfer Pumps Spotters & Stripers Icers & Glazers Custom Integrated Designs PACIFIC FRUIT PROCESSORS, INC. SOUTH GATE, CA | USA SINGLE PISTON FILLER/DEPOSITOR MODEL No.: SP-64B SERIAL No.: 0005537 MFG.

- Page 2 The 64 series industrial depositors are perfect for depositing and filling precise portions of food, bakery or specialty chemical based products. • Hummus, Guacamole, Salsa and Tzatiki • Cake and muffin batter with/without inclusions • Deli salads, soup, chili and stew •...

- Page 3 Many options are available for the 64 series such as hand depositing nozzles, product transfer pumps, hopper agitators, and spouts. Keep Production Running 24/7 Above: Hand depositing nozzle filling cups with apple pie filling. SP 64 depositor with P-128 transfer pump Below: 1”...

-

Page 4: Table Of Contents

TABLE OF CONTENTS SAFETY INSTRUCTIONS ......................3 WARRANTY ..........................4 ..........................5 ACHINE VERVIEW OVERVIEW ........................... 5 ........................5 OMPONENT XPLANATION ............................. 6 ALVE LABEL IDENTIFICATION AND E-STOPS ................6 ............................. 6 OWER OCKOUT ............................6 AFETY ABELS ..........................7 ECEIPT OF HIPMENT SETUP ............................ -

Page 5: Safety Instructions

Safety Instructions Definitions of label and instruction words and alerts Indicates a high risk hazard which if not avoided will result in death or serious injury. Indicates a medium risk hazard which if not avoided could result in death or injury. Indicates a low risk hazard which if not avoided could result in injury and/or damage to the equipment. -

Page 6: Warranty

WARRANTY SELLER WARRANTS EQUIPMENT OF ITS OWN MANUFACTURE TO BE FREE FROM DEFECTS IN MATERIALS AND WORKMANSHIP. THIS WARRANTY EXTENDS ONLY TO THE ORIGINAL BUYER AND IS LIMITED TO REPAIR OR REPLACEMENT F.O.B. SELLER'S FACTORY OF ANY ORIGINAL PART OR COMPONENT MANUFACTURED BY SELLER WHICH IS FOUND BY SELLER TO HAVE BEEN DEFECTIVE AT THE TIME OF SHIPMENT, PROVIDED WRITTEN CLAIM HAS BEEN RECEIVED FROM BUYER WITHIN SIX MONTHS OF SHIPMENT... -

Page 7: Overview

Overview Machine Overview: The Hinds-Bock SP-64 liquid depositor is designed to deposit liquid products such as sauces and batters. The Hinds-Bock machines are built with both the operator and the maintenance staff in mind. They are simple yet rugged, easy to operate, and to dismantle for either sanitation or routine maintenance. While it can handle a wide range product viscosities, this machine is not designed to work with products that have viscosities below that of water, which are abrasive, have large particulates, or any dry products. -

Page 8: Label Identification And E-Stops

Label Identification and E-Stops Air Dump Valve: To remove pneumatic energy from the system, use the air dump valve. This will exhaust all of the air from the system. This also acts as an E-stop. When the dial is turned to show “EXH” in the window, then the air is dumped. When performing maintenance tasks, the power disconnect switch must be locked using the in plant lock out tag out (LOTO) procedures. -

Page 9: Setup

Setup Receipt of Shipment: Immediately upon arrival, the Hinds-Bock machine should be uncrated and inspected for any damage that may have occurred during shipment. Check to see that all items listed on the packing sheet are included. If damages or shortages are noted, the transportation company and the Hinds-Bock Corporation should be notified immediately. - Page 10 with the factory is necessary, always include the model number and serial number. This will help to avoid errors and/or shipping delays. Parts must also be requested by part number. Air Connection: Under no circumstances should the air supply pressure exceed 125 psi. Air services should be brought to the machine.

-

Page 11: Production Start-Up

When the machine is done with the deposit, the blow off box is signaled to initiate the blow off. The round dial in the middle area of the box controls how long the blow off will last. To reduce the amount of time, turn the knob clockwise, and the opposite direction to increase the time. -

Page 12: Maintenance And Cleaning

Controlling the Machine: On the most basic level, the machine is controlled by either of two methods: Manual or Automatic. Manual cycling can be accomplished in the following ways: Hand operation, either air or electric, is accomplished by activating a switch by hand. ... - Page 13 Air Filter: The air filter protects the pneumatic system from excess particulates and condensation. The filter bowl is equipped with a normally closed auto drain feature. When condensation builds up in the filter bowl the float lifts, activating the drain. The air filter bowl on air assembly should be drained daily.

- Page 14 Removing the Product Piston: 1. Move the stroke adjust to its most retracted position (as shown). 2. Depending on the type of piston, it may need to be removed in one of the following ways: a. Unscrew pistons from the air cylinder foot. b.

- Page 15 Hinds-Bock Depositing System: Recommended Preventative Maintenance (where applicable) Item Part Action Frequency (weeks) Notes O-rings (moving parts) Clean, inspect, lubricate daily Product pistons, valves, spouts; lubricate with Petrol-Gel before each use. O-rings (moving parts) Replace Always replace when worn flat or damaged O-rings (stationary seals) Inspect for wear Improper seating is the most likely cause of...

Need help?

Do you have a question about the Hinds-Bock SP-64B and is the answer not in the manual?

Questions and answers