Advertisement

Quick Links

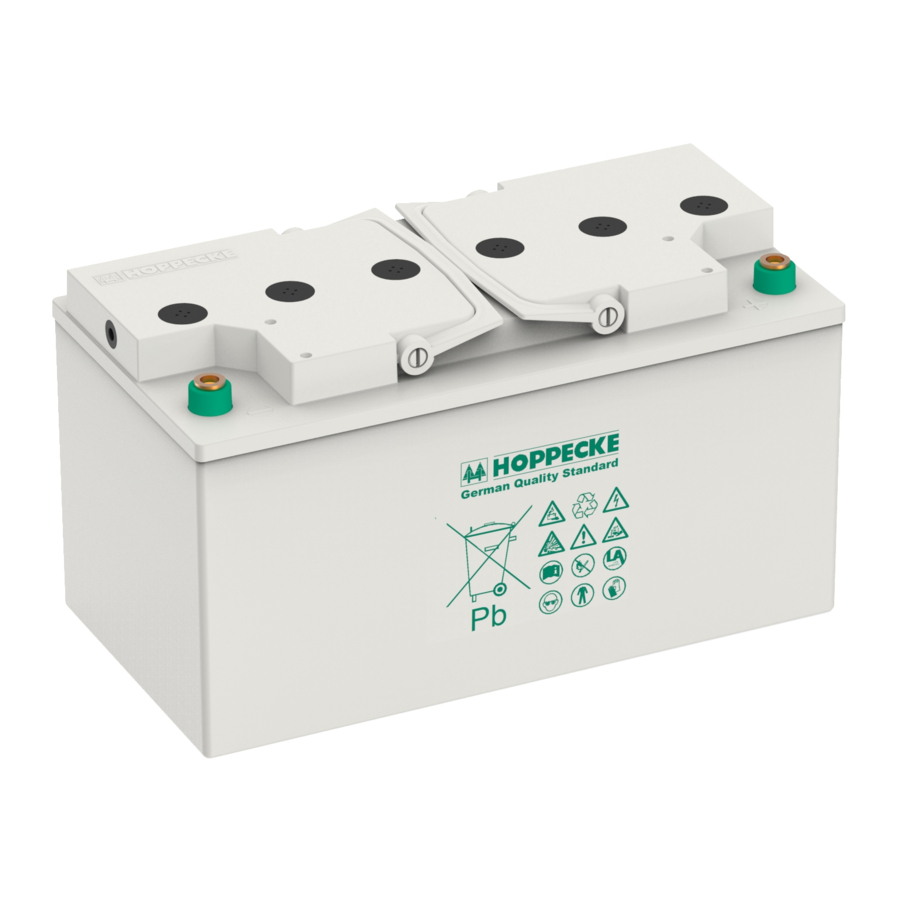

Lead-acid batteries with closed grid plate cells (trak

Rated values

1. Rated capacity:

2. Rated voltage:

3. Discharge current:

4. Rated temperature:

bloc batteries are closed batteries with suspended electrolytes that must not be topped

trak

®

up with water for the entire duration of the service life. Pressure relief valves are used as

sealing plugs. These valves stop oxygen getting into the cells and drain off any excess charging

gases. The valves must not be removed. During operation, the same safety requirements apply

to the closed batteries as to batteries with liquid electrolyte in order to prevent electric shock

and explosion of the electrolytic charging gases and to avoid the risk of corrosive electrolytes

if the cell container is destroyed.

Observe the usage instructions

and install in a visible position

at the charging bay. Only trained

personnel may perform work on

batteries.

Wear protective goggles, protec-

tive gloves and protective clo-

thing when working on batteries!

Observe the accident preventi-

on regulations as well as DIN

EN 50110-1 and IEC 62485-3.

During

installation/commissio-

ning, maintenance, cleaning and

disassembly wear additional face

protection (impact-resistant visor

according to EN 166 Class F).

Smoking is prohibited. There

must be no naked flames,

embers or sparks in the vicinity of

the battery, as this poses a risk

of explosion and a fire hazard.

Keep children away from bat-

teries!

Rinse eyes or skin splashed with

acid using plenty of clean water.

Then consult a doctor immedia-

tely. Wash clothing contaminated

with acid with plenty of water.

Electrolyte is highly corrosive.

Contact with electrolyte is not

possible during normal operation.

Risk of explosion and fire, avoid

short circuits!

Only use approved lifting and

transportation equipment, e. g.

lifting gear in accordance with

VDI 3616. Lifting hooks must

not cause any damage to cells,

connectors or connecting cables.

Operating instruction

see type plate

see type plate

C

/5 h or C

/20 h

5

20

30 °C

Dangerous electrical voltage.

Attention: Metallic parts of the battery cells

are always live. Therefore, no foreign objects

or tools may be placed on the batteries.

Warranty claims will no longer be valid in

the event of non-observance of the usage

instructions, repairs using non-original

spare parts or unauthorised intervention.

1. Start-up

The battery must be checked to ensure that

it is in mechanically perfect condition. The

installation area must be cleaned prior to

installation.

Only interconnect battery blocks with the

same charge state (same open-circuit vol-

tage, tolerance as per the following table).

Never power electrical consumers via a part

of the battery.

The battery terminal end must be connected

with the correct polarity and with reliable

contact. Otherwise, the batteries, the vehic-

le or the charging device may be destroyed.

Following assembly, the terminals must be

greased to protect against corrosion. The

battery must be recharged as per Item.

Rated

Maximum deviation

voltage

from mean value -

module

[V]

6

12

trak

®

Tightening torque for pole screws on the

terminal ends and connectors:

Cone terminal

Screw terminal M6/M8

Flat terminal M6

2. Operation

The regulations in accordance with Standard

EN 62485 – Safety requirements for

secondary batteries and battery installations

– Part 3 apply for the operation of vehic-

le batteries. Traction batteries for electric

vehicles.

2.1 Discharging

The battery valves must not be closed or

covered. Electrical connections (e. g. plug

connectors) must only be opened or closed

when in de-energised state.

In order to achieve an optimal service life,

discharge of over 60 % of the rated capacity

should be avoided. Discharge of over 80 %

of the rated capacity is a deep discharge

and is not permissible. These significantly

reduce the service life of the battery. Only

those discharge state indicators that have

been approved by the battery manufacturer

may be used.

Discharged batteries must be charged

immediately and must not remain in dischar-

ged state. This also applies to batteries in a

state of deep discharge. Otherwise, the

service life of the battery will be significantly

reduced. The battery may freeze when in

discharged state.

2.2 Charging

Batteries must only be charged with direct

current. The charging methods in accor-

dance with DIN 41773-1 must only be

applied in the modification approved by the

manufacturer HOPPECKE. Therefore, only

those chargers that have been approved by

the battery manufacturer HOPPECKE may

be used. In order to prevent overloading

of the electrical cables and contacts and

impermissible gas formation, the battery

U

bloc

must only be connected to the allocated

[V]

charger that is permissible for the respective

± 0,035

battery size.

± 0,049

bloc

bloc)

®

8 ± 1 Nm

20 ± 1 Nm

6 ± 1 Nm

Advertisement

Summary of Contents for Hoppecke trak bloc

- Page 1 Contact with electrolyte is not manufacturer HOPPECKE. Therefore, only possible during normal operation. those chargers that have been approved by the battery manufacturer HOPPECKE may Risk of explosion and fire, avoid Rated Maximum deviation be used. In order to prevent overloading...

- Page 2 It is also recommended that must be contacted for further testing or equalisation charging be carried out with A service contract with HOPPECKE makes repairs. constant current once every quarter. The it easier to detect faults in good time, to charging current can be a maximum of 0.8 A...

Need help?

Do you have a question about the trak bloc and is the answer not in the manual?

Questions and answers