Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Carlyle 05T

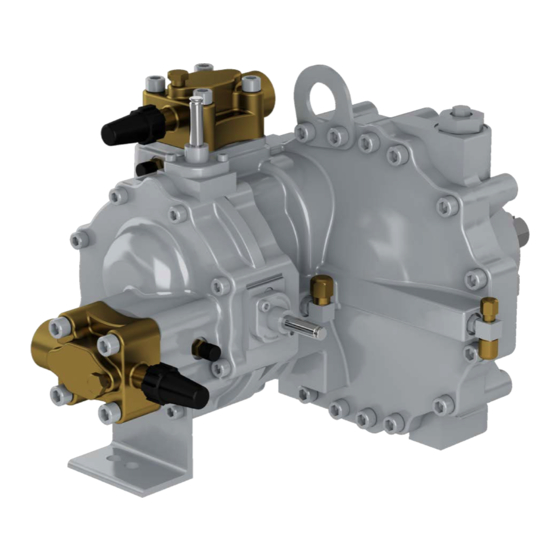

- Page 1 05T / 06T SCREW COMPRESSOR APPLICATION GUIDE...

-

Page 2: Table Of Contents

3.0 Oil Management System Features of Carlyle 05T/06T Compressors ..3 3.1 Oil Separator......9 Summary of Control Points 3.2 Piping Configuration . -

Page 3: General Introduction

General Introduction This manual is for the application of the Carlyle 06T semi- cooling, environmental chamber, and air conditioning hermetic and 05T open drive twin screw compressors. The applications. Screw compression technology yields the operational limits, required accessories, and operational... -

Page 4: Summary Of Control Points

Section 5.2 of this guide. Both UL and CSA approvals The Carlyle 05T/06T screw compressors may be rigid have been obtained for all voltage combinations listed in mounted. However, Carlyle recommends the use of isola- Section 5.3. -

Page 5: Ambient Conditions

Economizer ” ” ential of 400 psi (27.6 bar). The relief valve is not field All 05T compressors and 06T compressors between 65cfm serviceable. and 108cfm must use a flange at the discharge connection 1.8 Discharge Check Valve with an in-line ball valve for compressor isolation. With the... -

Page 6: Operating Specifications

2.0 Operating Specifications 2.1 Operational Envelopes outside of these envelopes requires approval from Carlyle Application Engineering or warranty is voided. Oil cooling The following operational envelopes, based on 65°F (18°C) can be achieved using an oil cooler or with desuperheating return gas, show the allowable operating suction and dis- valves (as described in Oil Cooling Systems, Section 3.8). -

Page 7: Vapor Temperature Limits

600 rpm/min for the 06T semi-hermetic compressors. frigerants and applications. The rate of compressor speed change for the 05T open- drive models is required to be no greater than 500 rpm/min. Vapor Temp Min. -

Page 8: Mechanical Unloading

See Appendix A for descriptions of (05/06TR only) operation applications for the LonCEM module. The 05T/06T screw compressors can be run unloaded con- 2.11 Mufflers tinually without affecting the reliability of the compressor. Screw compressors emit gas pulsations result in radiated High Discharge Pressure Control noise from the discharge line and oil separator. -

Page 9: Oil Management System

When testing the control circuit without the compressor across the oil separator. running, the oil line must be valved off so that the com- Steel oil piping is not recommended for use with 05T/06T pressor will not be filled with oil. screw compressor applications. - Page 10 EA02ZD100** * Operation with Evap. condensers below -25°F (-32°C) SST NOTE: A valve with a 190°F(88°C) temperature setting is may not require any additional desuperheating. Contact Carlyle required. Alternate desuperheating valve sizing or manufactur- Application Engineering for limits. ers must be approved by Carlyle Application Engineering.

-

Page 11: Oil Cooler Selection

Carlyle screw compressor systems. A sightglass is required in the main oil line. The sightglass NOTE: Use of the Carlyle 3 micron filter element is required. must be located after the oil filters and just prior to the first Use of a non-Carlyle- approved filter element will void com- compressor on a multiple compressor rack. -

Page 12: Oil System Schematics

Centistokes erant dilution. * If 170 POE oil is used, Carlyle recommends use of the next 3. Viscosity of 100 cSt is based on 100°F (38°C) oil, no larger size copper line if pressure drop is greater than 5.0 psi. -

Page 13: Refrigerant Management System

Mechanical subcooling via interstage manifolds are com- to efficiently distribute refrigerant gas to each compressor. monly applied with parallel 05T/06T rack designs. The gas Interstage headers should be designed similar to suction exiting the subcooler is used to provide additional motor line manifolds. - Page 14 INTERSTAGE SCHEMATIC WITH INJECTION TO MOTOR AND ROTORS Liquid Line from Condenser Liquid Injec on Liquid Injec on Motor Cooling Motor Cooling to Rotors to Rotors Injec on Valve Injec on Valve Mechanical Subcooler Interstage Header Check Solenoid Check Solenoid Isola on Isola on Valve...

-

Page 15: Electrical Protection

5.0 Electrical Protection 5.1Thermal Protection limit the maximum motor temperature to 240°F (116°C) and is an automatic reset device. Only one 5K sensor is used; The compressor motor windings are protected from ex- the other is a spare. The temperature vs. resistance charac- treme temperatures by the LonCEM module. -

Page 16: Overcurrent Protection

The code agency certifications of the 06T compressor is For part wind start applications Carlyle recommends a 1 to contingent upon the use of appropriate overcurrent protec- 1.25 second time delay between energizing the first and tion. -

Page 17: Motor Temperature Control

6.0 Motor Temperature Control 6.1 Motor Cooling Control required to distribute economizer gas to each compressor. A solenoid valve is required to isolate each compressor The motors in the 06T compressors are not located in the from this intermediate header when the compressor is not suction gas stream like other compressors. -

Page 18: Compressor Selections And Performance Data

The use of mechanical subcoolers are recommended to in- crease both the capacity and operating efficiency of the The performance of the 06T/05T screw compressors can compressors. Subcooler loads can also be estimated using be estimated using the CARWIN compressor selection tool. - Page 19 NOTES:...

- Page 20 NOTES: Lit. No. 574-030 Manufacturer reserves the right to discontinue, or change CARLYLE COMPRESSOR • © CARRIER CORPORATION 05/2021 P.O. Box 4808 • Syracuse, New York 13221 (Rev. G 5/21) at any time, specifications or designs and prices without www.carlylecompressor.com notice and without incurring obligations.

Need help?

Do you have a question about the 05T and is the answer not in the manual?

Questions and answers