Table of Contents

Advertisement

Quick Links

BVM Corporation Maintenance Manual

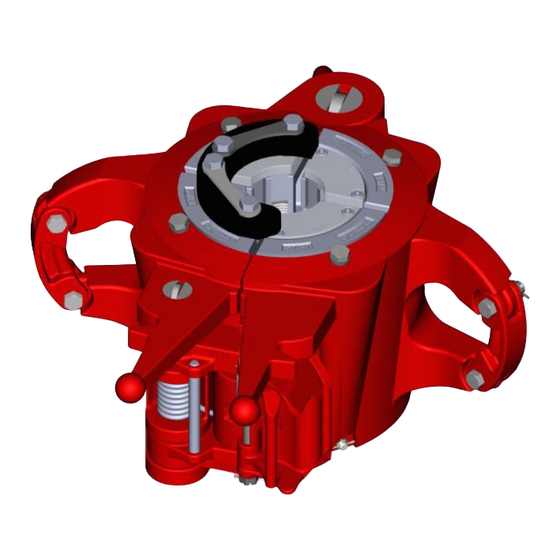

SERIES "Y" ELEVATOR

20, 40, 75, 125, 150, & 200 Tons

Part number: __________________

Serial Number: ________________

Safety

CAUTION: Practice safety in the operation and maintenance and use only approved

safety methods, materials and tools. Keep hands away from any pinch point or

undesignated areas; use only the provided handles for operating the elevator.

WARNING: Elevators which have experienced wear beyond established wear criteria set

by OEM, or are found to have cracks must be replaced or repaired by a BVM authorized

repair facility.

WARNING: Only original BVM parts may be used. Elevators are produced from cast

alloy heat treated steel and must not be welded in the field. Improper welding can cause

cracks and brittleness in heat-affected areas which can result in dramatic weakening of the

part and possible failure. Repairs involving welding and/or machining should be

performed only by a BVM authorized repair facility. Using an Elevator that has been

improperly welded or repaired is dangerous.

NOTE: The owner and user together with the manufacturer should jointly develop and

update inspection, maintenance, repair and remanufacture procedures consistent with

equipment application, loading, work environment, usage and other operational

conditions. These factors may change from time to time as a result of new technology,

equipment history, product improvements, new maintenance techniques and changes in

service conditions. Alternatively, BVM recommends using the Periodic inspection and

maintenance Categories and Frequencies as mentioned in API RP8B Table 1.

EN D 022 Rev D

Page 1 of 12

Advertisement

Table of Contents

Summary of Contents for BVM Y Series

-

Page 1: Safety

WARNING: Elevators which have experienced wear beyond established wear criteria set by OEM, or are found to have cracks must be replaced or repaired by a BVM authorized repair facility. -

Page 2: Table Of Contents

Description The BVM “Y” Series center latch slip type elevators are used for handling a variety of small casing (YC, MYC, & HYC) and tubing (LYT, MYT, YT, & HYT) with the proper size slips... -

Page 3: Operation

The slips are easily changed. The BVM elevator comes in sizes ranging from 1.315” through 7-5/8”, with a capacity of 20, 40, 75, 125, 150, & 200 tons. Elevators are made from alloy steel; load tested and are magnetic particle inspected. -

Page 4: Maintenance

Either condition could be hazardous to personnel and equipment. • Bodies and Doors should be matched by trained BVM personnel. For this reason, a body or door from one elevator should never be exchanged with a body or door from another elevator. -

Page 5: Inspection

5. Grease springs. 6. Grease link retainer fasteners. Inspection (PER API-RP8B) Daily Inspection (Cat. II – elevator in use) 1. Check for any worn and damaged parts. 2. Check for loose and missing parts. 3. Check condition of the latch spring and the latch lock spring. 4. - Page 6 Wedge here to test latc h (Fig. 1b) Body Pry here Latc h to test latc h (Fig.1a) (Fig 1c ) Correc t Wrong Figure 1: Latch wear inspection Minimum c learance 1/8” T op and Bottom Correc t Wrong Wrong Figure 2: Latch wear inspection EN D 022 Rev D...

- Page 7 Degree 1 Degree 2 Internal chills, chaplets None Degree 1 Porosity Degree 1 Degree 2 Note: Only BVM authorized repair facilities are allowed to repair elevators with indications outside the acceptance criteria. EN D 022 Rev D Page 7 of 12...

-

Page 8: Wear Data

Additionally any weld repairs – not done at a BVM authorized repair facility – shall require examination and re-certification by a BVM authorized repair facility before being used further. -

Page 9: Critical Area Drawings

Critical Area Drawings Figure 4: Elevator Body Critical Wear Areas Figure 5: Latch critical area drawings EN D 022 Rev D Page 9 of 12... -

Page 10: Storage & Transportation

3. Clean the tool after use – steam clean as needed; remove mud, debris and any other substances. 4. Transport the unit on a suitable container or pallet. Troubleshooting When problems cannot be solved, contact an authorized BVM repair facility. Overview possible problems: Problem Possible cause Possible solution Parts bent or damaged. -

Page 11: Risk Assessment According To En-Iso 12100:2010

• Have knowledge of rig procedures. • Must have been instructed for safe use of the tool. • Always use secondary retention as established and implemented by BVM. • Do not rely on visual signals “elevator closed and latched” from deckhand. -

Page 12: Recommended Spares For 1 Year Of Operation

Recommended Spares for 1 year of Operation Model Rating 28750 29328 23105 39284 24140 24139 55310 Assembly PN 28750-SP 29328-SP 23105-SP 39284-SP 24140-SP 24139-SP 55310-SP Spare Part kit Part Number Component 28753 29333 23116 39239 24181-1 200364-1 55311 Hinge pin 30644 30652 15348...

Need help?

Do you have a question about the Y Series and is the answer not in the manual?

Questions and answers