Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Boart Longyear S36

- Page 1 S36 ROCKDRILL PARTS & SERVICE MANUAL...

- Page 2 It generally Indicates an imminently hazardous situation, indicates an Operational Aid. which if not avoided, will result in serious injury. S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021...

- Page 3 NO CLAIM AGAINST PRODUCT WARRANTY will be considered by the manufacturer if these procedures have not been followed. NO CLAIM AGAINST PRODUCT WARRANTY will be considered by the manufacturer if Boart Longyear Replacement Parts are not used in repair. All rockdrill repairs should be performed by properly trained and equipped service technicians.

-

Page 4: Table Of Contents

Boart Longyear products. Contact your nearest Boart Longyear representative or visit www.boartlongyear.com for information on the latest product improvements and manual revisions. S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021... -

Page 5: Introduction General Information

Standard Warranty A. Consumables The purpose of this manual is to furnish the Service Boart Longyear warrants for a period of one (1) year Technician with detailed information to achieve the after the date of shipment of the consumable products maximum operating performance from the drill. - Page 6 (i) normal wear and tear; to Boart Longyear under any contract or by implication or operation of the law to the extent that the benefit of any (ii) corrosion, abrasion or erosion;...

-

Page 7: Ordering Parts

If you desire to return parts, whether for repairs, or customer service representative. A schematic of replacement, or warranty, please contact our order parts can be found on the S36 Rockdrill Wall Chart, desk with the following information: quantity, part available for download at www.boartlongyear.com. -

Page 8: Rockdrill Repair Shop

• Belt Grinder c/w piston support • Torch Set c/w tanks • Welder M/C (optional) • Parts Cabinet - eight drawer • Pin Skids • Electric Rewind Extension Cord • Lighting over work bench S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021... -

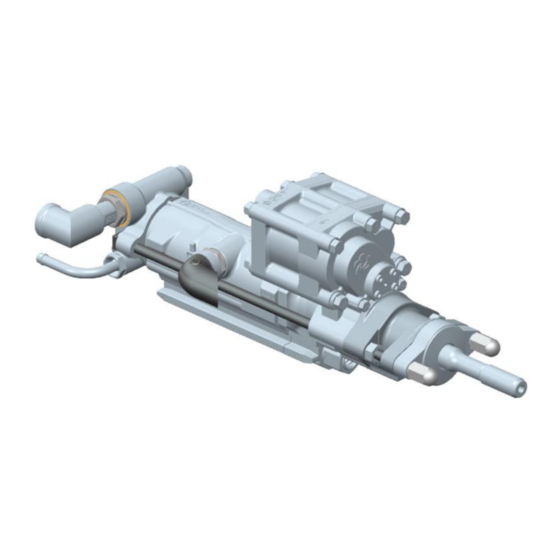

Page 9: Exploded View

CHAPTER 4 Maintenance Procedures S36 Rockdrill - Exploded View S36 Rockdrill - Parts List S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021... -

Page 10: Maintenance Routine

Ref. 33 and tapping the bearing out with a small drift through the opened hole. 12. The compound gear Ref. 41 can be removed from the pinion by unscrewing the eight cap screws Ref. 40. S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021... - Page 11 21. The water stem Ref. 11 may be removed from the backhead by unscrewing the nut Ref. 13. Make sure that the internal components, the thrust pad Ref. 17, thrust washer Ref. 15 and rubber Ref. 16 are not lost. S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021...

-

Page 12: Inspection Of Components

• This should be cleaned and checked for burrs bearings, if they do not, the bearings should be on faces and bearing surfaces. Any burrs checked and replaced if necessary. should be carefully removed. S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021... -

Page 13: Assembly Guide

10. Fit the assembled air motor and reduction housing over the front cylinder Ref. 67 already fitted into the main cylinder Ref. 58. S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021... - Page 14 18. The air inlet stem Ref. 1 can be assembled into the air inlet bend Ref. 5 making sure the nut Ref. 4 is in place first. Always use a new copper washer Ref. 3 when replacing the air stem. S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021...

-

Page 15: Testing Procedures

3. Clamp down drill in aluminum slide. 4. Slowly turn on air supply to ensure proper operation of rockdrill. DO NOT operate rockdrill wide open on bench test. S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021... -

Page 16: Startup And Lubrication Procedures

Oil should be visual on the outside at the fronthead and striking bar. Water should flow out of the striking bar or through the steel if it is fitted. The drill is now ready for work. S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021... -

Page 17: Troubleshooting Guides

Lack of oil cylinder will be warm • • Worn piston - replace and Loss of fronthead cushion check for outer flange wear • Worn front cylinder liner- check and replace if necessary S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021... - Page 18 Change water tube seal tube seal • • Piston chipped or broken Damaged striking bar face Reface piston so that axis is at right angles to striking face • Inspect/replace striking bar S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021...

- Page 19 Faulty lubrication • Inspect lubricator • • Dirt in drill Inspect lubricator screen • Broken Striking Bar Incorrect rockdrill alignment while drilling • Worn front locking plate • Worn centralizer jaws S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021...

-

Page 20: Drilling

Keep the drill string attempting to add or remove a drill rod. oscillating slightly at all times while drilling. 4. Shift the percussion lever completely forward. S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021... -

Page 21: Rod Pulling

Always ensure that rockdrill rotation has come to a complete stop before attempting to add or remove a drill rod. S36 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021...

Need help?

Do you have a question about the S36 and is the answer not in the manual?

Questions and answers