Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for VM CBF 125

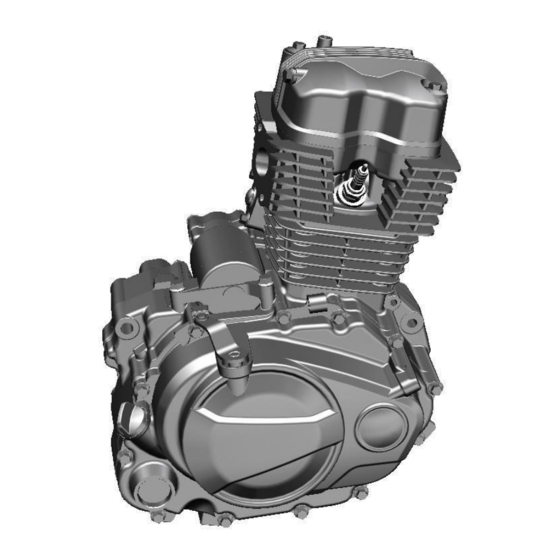

- Page 1 CBF 125 ENGINE - AIR COOLING SERVICE MANUAL AND EFI DIAGNOSTIC...

- Page 2 CBF 150 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI INDEX 1、MAIN TECHNICAL PARAMETERS 2、GENERAL MAINTENANCE 3、LUBRICATION SYSTEM 4、CYLINDER HEAD PARTS MAINTENANCE 5、CYLINDER BLOCK AND PISTON 6、RIGHT COVER/ CLUTCH / BALNACE GEAR / GEARSHIFT 7、LEFT COVER / STARTING MOTOR SYSTEM / MAGNETO 8、CRANKCASE (EXTRACTION INSTALATION) 9、MIKUNI EFI DIAGNOSTIC SYSTEM (XTREET 125)

- Page 3 CBF 150 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI MAIN TECHNICAL PARAMETERS Item Specification Model number CBF 125 Single-cylinder, air -cooling, four- Type stroke, camshaft upward upward Bore X stroke Φ52.4×57.8mm Piston Displacement 124.6 C.C. Compression ratio 9.2:1 Open (...

- Page 4 CBF 150 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 1.4 Maintenance Parameters: Item Standard Service Limit Specification SJ 10W/40 1.2 L when filter is not removed Engine oil when filter is removed 1.1 L Capacity when engine is dry 1.2 L Valve 0.04-0.06mm...

- Page 5 CBF 150 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 1.6 Cylinder and Piston unit: mm Item Standard Service Limit Inner diameter of cylinder Φ52.5 Φ52.400~φ52.410 Cylinder Cylindricity 0.004 0.10 Planeness of cylinder face 0.03 0.10 Outer diameter of piston Φ52.3 Φ52.38~φ52.39 Inner diameter of piston pin hole...

- Page 6 CBF 150 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 1.7 Clutch unit:mm Item Standard Service Limit 41.1-41.9 Clutch Spring Free Length 2.92-3.08 Friction Plates Thickness Clutch flatness of clutch driven plate 0.20 Driven gear inner hole diameter Φ23.000 ~φ23.021 φ23.08 Collar diameter Φ22.93...

-

Page 7: Table Of Contents

CBF 150 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI GENERAL MAINTENANCE 2.1. ENGINE MAINTENANCE CYCLE .....................- 8 - 2.2. ENGINE MAINTENANCE STANDARDS...................- 8 - 2.3. TORQUE STANDARS ........................- 8 - 2.4. SPARK PLUG MAINTENANCE......................- 9 - 2.5. VALVE CLEARANCE ADJUSTMEN-....................- 10 - 2.6. -

Page 8: Engine Maintenance Cycle

CBF 150 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 2.1 Engine Maintenance Cycle Cycle Travel Travel Kms(×1000 Km) Inspection Maintenance Spark Plug Valve Clearance Engine Oil Fuel Filter Oil Strainer Oil Filter Idle Speed I: Inspect, clean, adjust, lubricate or replace if necessary. C: Clean R: Replace IMPORTANT NOTE: to guaranty the perfect function of fuel injection system, the fuel filter must... -

Page 9: Spark Plug Maintenance

CBF 150 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 2.4 Spark Plug Maintenance Suggested Spark Plug Reference Standard Use CPR8EA-9(NGK) High RPM Extreme Use CPR9EA-9(NGK) Note: Using wrong spark plug specification can damage the engine. If the lateral and center electrode have erosion or covered with accumulation of carbon, the spark plug shall be cleaned or replaced. -

Page 10: Valve Clearance Adjustmen

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 2.5. Valve Clearance Adjustment Too large valve clearance will result in noise and ultimately in damage of engine. Too small valve clearance or no clearance will result in that valves are not closed tightly, thus causing valve damage and power loss of the engine. - Page 11 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI Tighten caps of large and small view holes, respectively. Install upper cover of cylinder head, and check the engine for leakage.

-

Page 12: Oil Level Inspection

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 2.6. Oil level inspection 2.6.1 Check engine oil before driving every day. 2.6.2 Oil level must be between the upper and lower lines of the oil level gauge. 2.6.3 Start the engine and let it idle for 3- 5minutes. -

Page 13: Oil Change

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 2.7 Oil change Engine oil quality is the main factor, affecting engine service life. Change the engine oil as specified in the maintenance schedule (refer to 2.1 section). When the driving is done in very dusty conditions, oil changes should be performed more frequently than specified in the maintenance schedule. - Page 14 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 2.7.7 Remove the open pin, oil filter, pipe and spring 2.7.8 Check if the open pin, oil filter outlet pipe and spring are damaged. If they are, replace them with new ones 2.7.9 Assembly the open pin, Oil filter, outlet pipe and...

- Page 15 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI LUBRICATION SYSTEM 3.1 Lubrication system (schematic diagram)..................- 16 - 3.2 Lubrication system (technical specifications)...................- 17 - 3.3 Troubleshooting: ..........................- 17 - 3.4 Oil pump (extraction and installation) ..................- 18 -...

-

Page 16: Lubrication System (Schematic Diagram)

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 3.1 Lubrication system (schematic diagram) -

Page 17: Lubrication System (Technical Specifications)

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 3.2 Lubrication system (technical specifications) Unit: mm Item Standard Service Limit Specification SJ 10W/40 when filter is not removed Engine oil Capacity when filter is removed 1.1L when engine is completely dry 1.2L... -

Page 18: Oil Pump (Extraction And Installation)

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 3.4 Oil pump (extraction and installation) 3.4.1. Oil pump dismantle 3.4.1.1 Dismantle right cover (refer to 6.5 section), then remove circlip and take out gears of oil pump. 3.4.1.2 Take out the pin and remove fastening bolt of oil pump. - Page 19 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 3.4.2.2. Remove the inner rotor, pin and pin shaft from oil pump. 3.4.2.3. Take out outer rotor of oil pump and clean the components disassembled thoroughly. 3.4.3. Check of oil pump...

- Page 20 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 3.4.3.2. check fit clearance between outer and inner rotors of oil pump; Service limit 0.20mm 3.4.3.3. Take out the shaft and pin from the oil pump; Use knife straight edge and feeler gauge to measure axial clearance between rotor and casing of the oil pump.

- Page 21 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 3.4.4.1. Apply lube oil on the circumference of outer rotor and install the rotor into oil pump casing. 3.4.4.2. Apply lube oil on the circumference of inner rotor, pin shaft and pin and install them into oil pump casing.

- Page 22 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 3.4.4.5. Assemble oil pump and tighten the bolt. Assemble the pin. 3.4.4.6. Install oil pump gears onto pin shaft and install circlip. Apply an appropriate amount of lube oil on the gears.

- Page 23 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI CYLINDER HEAD PARTS MAINTENANCE 4.1. CYLINDER HEAD EXPLODED VIEW....................- 24 - 4.2. UPPER COVER OF CYLINDER HEAD MAINTENANCE................- 25 - 4.3. ROCKER ARM SET MAINTENANCE ....................- 27 - 4.4. CYLINDER HEAD SET MAINTENANCE ....................- 34 -...

-

Page 24: Cylinder Head Exploded View

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.1 Cylinder Head exploded view... -

Page 25: Upper Cover Of Cylinder Head Maintenance

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.2 Upper cover of cylinder head maintenance 4.2.1 Remove two bolts form upper cover of cylinder head 4.2.2 Take out upper cover and corresponding seal gasket 4.2.3 Positioning pin and O-ring for removing the oil path 4.2.4 Remove the washer and screw from upper cover... - Page 26 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.2.5 Detecting oil passage and clean it using air gun 4.2.6 Assemble bolts and washers after the head cover is checked (Need to be replaced old washer by a new one) 4.2.7 Assembly location pin and a new O-ring...

-

Page 27: Rocker Arm Set Maintenance

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.2.9 After confirming that the upper cover is installed at right place, install rubber gasket of bolt of cylinder head (with mark UP upwards). 4.2.10 Assembling head cap upper cover bolts and tighten. - Page 28 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.3.1.3. Remove the fastening bolts from timing sprocket chain. 4.3.1.4、Remove the timing sprocket chain, Care shall be taken when using a tool to fix the chain to avoid dropping it into the crankcase.

- Page 29 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.3.1.5. Remove AB Nut, to take out the ROCKER ARM 4.3.1.6. Loosen fastening bolt on stop plate and remove the stop plate. Then remove camshaft. 4.3.1.7. Remove fastening bolt of rocker arm shaft...

- Page 30 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.3.1.9. Check bearing at both ends of camshaft for free rotation. 4.3.1.10 、 Inspect the cam for abrasion Service limit: Inlet: 31.8 mm Exhaust: 31.5mm 4.3.1.11. And check rocker arm shaft for wear Service limit 9.91mm...

- Page 31 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI Installation rocker arm set 4.3.2. 4.3.2.1. Apply the right amount of lube oil on Rocker shaft hole, roller and rocker arm shaft before installing them 4.3.2.2. Assemble rocker arm and rocker shaft in accordance with sequence shown in the illustration 4.3.2.3.

- Page 32 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.3.2.5. Before installing camshaft, apply appropriate amount of lube oil on the circumference of bearings (at both ends). Then apply appropriate amount of SO grease into cams. 4.3.2.6. Mounting the camshaft into the rocker bracket, take special attention to the projected point on flange shall be upward, as shown in the figure.

- Page 33 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.3.2.9. Apply appropriate amount of lube oil onto both sides of gasket and external surface of nut, then install them into rocker arm bracket. 4.3.2.10. Tighten AB bolt nut in turns Fastening torque: 35N •...

-

Page 34: Cylinder Head Set Maintenance

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.3.2.13. Assembling fastening Bolts Fastening torque: 9N • m 4.3.2.14. Loosen tensioner device, to check if chain is tensioned 4.3.2.15. Replace O-ring with a new one and assemble the tensioning screw. - Page 35 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.4.1.2. move the cylinder head assembly 4.4.1.3. Remove the cylinder head seal gasket and the two position pins 4.4.1.4. Use special tooling to dismantle valve collet seat ring, valve, valve steam seal and valve spring respectively.

- Page 36 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.4.2. heck of cylinder head assembly 4.4.2.1. Check the cylinder Head combustion chamber, clean the carbon deposit; 4.4.2.2. ck valve spring for free length. In: 37.8 mm Outer: 40.8 mm 4.4.2.3.

- Page 38 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.4.3. Assembly of Cylinder head set Cylinder head exploded view 4.4.3.1. Assemble the components according to the order of exploded view. 4.4.3.2. When installing valve spring, care shall be taken that the spring dense coil end shall be directed downwards.

- Page 39 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.4.3.3. The completed cylinder head assembly shall be subject to air tightness test. Next operation shall not be done unless the cylinder head assembly is confirmed air- tight. 4.4.3.4. Assembly positioning pins and a new cylinder head sealing gasket.

-

Page 40: Tensioner Device (Extraction And Installation)

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.5. Tensioner device (extraction and installation) 4.5.1. Remove the screw of the tensioning device 4.5.2. Use the right tools to adjust the tensioning device until loosen position. - Page 41 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 4.5.3. Assembly of Tensioner device 4.5.4. Replace O ring with a new one 4.5.5. Tighten the screw...

- Page 42 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI CYLINDER BLOCK AND PISTON 5.1. CYLINDER BLOCK/PISTON EXPLODED VIEW- ................- 43 - 5.2. LIMITS FOR SERVICE ........................- 44 - 5.3. TROUBLESHOOTING........................- 44 - 5.4. CYLINDER BLOCK – PISTON (DISASSEMBLY AND INSPECTION ) ............- 45 -...

-

Page 43: Cylinder Block/Piston Exploded View

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 5.1 Cylinder block/piston exploded view... -

Page 44: Limits For Service

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 5.2 Limits for service Cylinder and Piston unit:mm Item Standard value Service Limit Inner diameter of cylinder Φ52.5 Φ52.400~φ57.410 Cylinder Cylindricity 0.004 0.10 Flatness of cylinder face 0.03 0.10 Outer diameter of piston Φ52.3... -

Page 45: Cylinder Block - Piston (Disassembly And Inspection )

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 5.4 Cylinder block - piston (disassembly and installation) 5.4.1 Disassembly and inspection of cylinder block 5.4.1.1. Dismantle cylinder head (refer to 4.2 section). Remove the guide plate 5.4.1.2. Knock cylinder block slightly with rubber hammer to separate cylinder block from crankcase. - Page 46 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 5.4.2. heck cylinder block 5.4.2.1. Check diameter of cylinder bore. When doing this task, measure the diameter at three layers respectively, i.e. top, middle and bottom of piston stroke, and measurement shall be taken at two directions mutually perpendicular at every layer.

- Page 47 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 5.4.3. Piston disassembly 5.4.3.1. Place a clean cloth under the piston to guard against that circlip of piston pin falls into crankcase during removal. 5.4.3.2. Use long-nose pliers to remove circlip of piston pin.

- Page 48 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 5.4.4. heck piston 5.4.4.1. Check piston for damage or break. Check diameter of skirt at 8mm height. Limit value Φ52.3mm 5.4.4.2. After measure diameters of cylinder bore and piston skirt, calculate their fit clearance .

- Page 49 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 5.4.4.8. check gap of piston ring. Install piston ring into cylinder block, and press them down with piston. Check gap of each piston ring with feeler gauge. Top ring 0.40mm...

- Page 50 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI...

- Page 51 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI Note: • Do not damage piston and piston rings during assembling. • Check if piston ring can rotate freely on the piston without any seizure after rings are assembled. •...

- Page 52 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI Note Do not damage piston surface and cylinder block. 5.4.5.1. Assembly piston When is assembled piston, direct face with mark IN towards intake side. Then assemble piston pin. Apply appropriate amount of lube oil on piston pin, piston pin hole, piston skirt before assembling.

- Page 53 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI Install guide plate of chain into cylinder block Note: Guide plate shall be installed to its place as shown in the figure; otherwise, the plate may be damaged abnormally. Assemble cylinder head and tensioner. (refer to 4.4...

- Page 54 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI RIGHT COVER / CLUTCH / BALANCING GEAR / GEARSHIFT 6.1. EXPLODED VIEW OF RIGHT COVER/ CLUTCH/ BALANCED GEAR/ GEARSHIFT ......- 55 - 6.2. CLUTCH (TECHNICAL SPECIFICATIONS) ..................- 56 - 6.3. TIGHTENING TORQUE REQUIREMENTS..................- 56- 6.4.

-

Page 55: Exploded View Of Right Cover/ Clutch/ Balanced Gear/ Gearshift

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 6.1. Exploded view of right cover/ clutch/ balancing gear/ gearshift... -

Page 56: Clutch (Technical Specifications)

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 6.2. Clutch (technical specifications) Clutch Unit: mm Item Standard Value Service Limit 41.1-41.9 Clutch Spring Free Length 2.92-3.08 Friction Plate Thickness Clutch Flatness of clutch driven plate 0.20 Driven gear inner hole diameter φ23.08... -

Page 57: Right Cover -Extraction And Installation

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 6.5. Right cover -extraction and installation- • First drain off oil from engine, remove bolts from right cover. • Remove the paper gasket and positioning • Check the crankshaft oil seal is intact •... - Page 58 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI • Take out clutch control arm and oil seal • Check clutch control arm for deformation, check iif pushing rod and spring are damaged if they are, replace them with new ones •...

- Page 59 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI • Rotate control arm, so that spring falls into position as shown in figure. Then install pushing rod of clutch . • Assembly location pins and new paper gasket. •...

-

Page 60: Clutch (Extraction And Installation)

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI Clutch (extraction and installation) 6.6.1. Clutch extraction. • Dismantle 4 bolts from end cover of clutch, then take out end cover of clutch, bearing, declutch spring. • Dismantle locknut and... - Page 61 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI • Take out declutch shaft sleeve 6.6.2. Checking of clutch • Check bearing of clutch for free rotation. • Check declutch spring of clutch for damage. Measure free length of spring.

- Page 62 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI • Check if drive friction plates discolors, measure thickness of drive friction plate. Service limit 2.6mm • Check driven friction plates flatness. Service limit 0.20mm • Check outer case of clutch and shaft...

- Page 63 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 6.6.3. Clutch assembly • Apply appropriate amount of engine oil onto internal and external surface of shaft sleeve, then assemble declutch shaft sleeve onto main shaft • Apply appropriate amount of lube oil onto gears.

-

Page 64: Gearshift Arm (Extraction Installation)

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI • Assemble gaskets and nuts. Apply appropriate amount of engine oil onto end face of nut • Use tools to fix pressure plate and tighten locknut of clutch. Tightening torque... - Page 65 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 6.6.2. Remove bolt of star-shaped plate, then dismantle the plate 6.6.3. Dismantle components and parts in order: 6.6.3.1. 6.6.3.2. Locating plate Locating plate bolt 6.6.3.3. Locating plate spring 6.6.3.4. Washer 6.6.3.5.

- Page 66 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 6.6.6. After displace locating plate with flat screwdriver, assemble pin and star-shaped plate. Pin holes on the star-shaped plate shall be aligned with two cylindrical pins. 6.6.7. Tighten bolt on star shaped plate Tightening torque 12 N.m.

-

Page 67: Drive Gear - Balancing Gearshift Arm (Extraction And Installation)

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 6.8. Drive gear – balancing gearshift arm (extraction and installation) 6.6.1. Balancing drive gear extraction 6.6.1.1. Dismantle locknut and washer of drive gear 6.6.1.2. Take out drive gear. 6.6.1.3. Take out balancing gear... - Page 68 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 6.6.2.4. Align keyway on drive gear with woodruff crankshaft assemble them. Apply appropriate amount of engine oil on gears. 6.6.2.5. Assemble oil filter, washer, locknut 6.6.2.6. Tighten nut to specified torque;...

- Page 69 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 6.6.3. Balancing driven gear extraction 6.6.3.1. Dismantle locknut and washer. 6.6.3.2. Take out shaft sleeve and woodruff key. 6.6.3.3. Balancing driven Gear (Disassembly and assembly). • Dismantle circlip, washer, disc washer, flat washer in turn;...

- Page 70 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI • Apply engine oil on matching face between gear and hub. • Install buffer rubber bushing on right position on the hub. • Install driven gear onto the rub. •...

- Page 71 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 6.6.4. Assembly of driven gear of balancing shaft 6.8.1.1. Assemble shaft sleeve and woodruff key onto balancing shaft Note damage circumference balancing shaft and keyway 6.8.1.2. Align keyway of balancing driven gear with woodruff key on balancing shaft.

- Page 72 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 7. LEFT COVER / STARTING MOTOR SYSTEM / MAGNETO 7.1. EXPLODED VIEW OF LEFT COVER/ STARTING MOTOR SYSTEM/ MAGNETO ......- 73 - 7.2. LEFT COVER (EXTRACTION AND INSTALLATION)..............- 74 - 7.3.

- Page 73 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 7.1. Exploded view of left cover/ starting motor system/ magneto...

- Page 74 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 7.2. Left cover (Extraction and installation) 7.2.1. Take out gearshift switch harness from harness groove. 7.2.2. Loosen fastening bolt on left cover and remove left cover 7.2.3. Take out locating pin and paper gasket.

- Page 75 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 7.2.5. Insert gearshift switch harness into harness groove on left cover 7.3. Starting motor system (extraction and installation) 7.3.1. Dismantle left cover and take out shaft sleeve, dual gear shaft and dual gear 7.3.2.

- Page 76 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 7.3.4. Dismantle locknut on magneto. Use special tools to dismantle magneto rotor 7.3.5. Check needle bearing, woodruff key on crankshaft for damage 7.3.6. Clean off engine oil from tapered face of crankshaft.

- Page 77 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 7.3.8. Use tools to fix magneto and tighten nut to specified torque. Tightening torque: 65 N.m. 7.3.9. Replace O-ring with a new one. Apply appropriate amount of lube oil onto O-ring before assembling.

- Page 78 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 7.3.12. Starting motor system check. Assemble large starting gear onto magneto rotor, then check if the gear can rotate normally, making rotate counterclockwise 7.3.13. Magneto rotor disassembly. 7.3.13.1. Use special tools to fix rotor, then dismantle rotor bolts.

- Page 79 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 7.3.13.4. Check teeth of large starting gear for damage Measure outer diameter of large starting gear Service limit 45.60mm 7.3.13.5. Magneto rotor exploded view...

- Page 80 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 7.3.13.6. Assemble overrunning clutch 7.3.13.7. Install overrunning clutch onto magneto rotor, and align through hole with threaded hole 7.3.13.8. Apply appropriate amount fastening adhesive onto threads of bolts, then use tools to locate and tighten the bolt Tightening torque: 16 N.m.

- Page 81 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 7.4. Magneto stator (extraction and installation) 7.4.1. Remove rubber plug, magneto cable clip and sensor 7.4.2. Dismantle fastening bolts on stator and take out magneto 7.4.3. Install a magneto onto left cover, then tighten bolts 7.4.4.

- Page 82 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8. CRANKCASE (EXTRACTION AND INSTALLATION) 8.1. CRANKSHAFT (EXPLODED VIEW) ...................- 83 - 8.2. TECHNICAL SPECIFICATIONS ....................- 84 - 8.3. CRANKSHAFT EXTRACTION....................- 85 - 8.4. DRIVE TRAIN (EXTRACTION AND CHECK) .................- 87 - 8.5.

- Page 83 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.1. Crankcase (exploded view)

- Page 84 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.2. Technical specifications unit: mm Item Standard Service Limit Crankshaft, Radial Clearance 0~0.008 0.03 Connecting Rod Connecting Large End: Side Clearance 0.1~0.35 Rods Crankshaft Runout 0.03 0.08 Φ9.966~φ9.984 Φ9.93 Fork Outer diameter Φ10.000~φ10.018...

- Page 85 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.3. Crankshaft extraction 8.3.1. Dismantle corresponding components and parts (cylinder head, cylinder block, right cover, left cover) in accordance with steps described above. 8.3.2. Loosen and dismantle fastening bolt on chain...

-

Page 86: Crankshaft (Exploded View)

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.3.6. Dismantle fastening bolt right crankshaft 8.3.7. Dismantle fastening bolts on crankshaft 8.3.8. Place crankcase properly with right half downwards. Knock counter shaft and crankshaft with rubber hammer to loosen adhesive on halves (left and right). -

Page 87: Drive Train (Extraction And Check)

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.3.10. Check chain tension plate for severe wear or damage. If there is, replace the tension plate with a new one 8.4. Drive train (extraction and check) 8.4.1. Take out fork shaft of main and counter shafts 8.4.2. - Page 88 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.4.4. Check main and counter shafts 8.4.4.1. Disassemble gears on main and counter shafts. 8.4.4.2. Check gears for severe wear or damage. Check inner diameter of the gears Φ20.04mm Φ20.04mm Service Φ20.55mm...

- Page 89 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI Check spline key and main and counter shaft for abnormal wear and damage Measure diameter shaft gear-matching position. Service limit φ16.93mm of outer φ16.93mm diameter of φ19.94mm main and counter φ19.95mm...

-

Page 90: Bearings Extraction

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.4.5.3. Check fork shaft for abnormal wear and damage. 8.4.6. Replacement of bearings 8.4.6.1. Turn inner race of bearing to check if it can rotate freely 8.4.6.2. Check bearing cage and balls, looking for severe wear and damage 8.5. - Page 91 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.5.3. Dismantle counter shaft and gearshift arm oil seals, located on left half. 8.5.4. Dismantle bearings from left half using a bearing puller tool...

-

Page 92: Bearings Installation

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.6. Bearing installation 8.6.1. Apply appropriate amount of engine oil on outer race bearing, then press the bearings into corresponding holes with special tools Note Bearing shall be installed using special tools. -

Page 93: Drive Train Assembly

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.7. Drive train assembly 8.7.1. Clean the components and parts with cleaning agent 8.7.2. Dry the cleaned components and parts using air, then apply engine oil on it. 8.7.3. Apply appropriate amount of grease onto... - Page 94 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.7.5. Main shaft (Exploded view) 8.7.6. Counter shaft (exploded view)

- Page 95 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.7.7. Apply appropriate amount of lube oil onto fork groove and gears 8.7.8. Install main and counter shafts into right half of crankcase. Care shall be taken to not miss washers at both ends of the shafts 8.7.9.

-

Page 96: Crankshaft Check

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.7.11. Apply appropriate amount of engine oil onto fork shaft and insert the shaft into fork hole. Rotate counter shaft check components and parts are installed in the right positions, and main and counter shafts can rotate freely 8.8. - Page 97 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.8.4. Measure side clearance between large-end of connecting rod and crankpin using feeler gauge Service limit 0.5mm 8.8.5. Measure connecting rod radial clearance, at the large end Service limit 0.05mm Check timing drive sprocket on crankshaft for abnormal wear and damage.

-

Page 98: Crankcase Installation

CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.9. Crankcase installation 8.9.1. Install crankshaft into right half of crankcase 8.9.2. Install balanced shaft. 8.9.3. Clean matching faces on left and right halves of crankcase. Apply sealing adhesive on... - Page 99 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.9.5. Assemble left half of crankcase onto right half. Note When installing left half of crankcase, if it is found that the two halves cannot bind closely together, check if the components...

- Page 100 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 8.9.9. Install pressing body pressing pin body spring. Note Tapered face of pressing pin body shall contact bearing. 8.9.10. Apply adhesive to thread on 2/3 of length, then install pressing pin body guard and bolts onto crankshaft case.

- Page 101 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 9. MIKUNI EFI DIAGNOSTIC SYSTEM XTREET 125 EFI 9.1. GENERAL INFORMATION .......................- 102 - 9.2. STEPS TO MAKE THE DIAGNOSTIC..................- 102 - 9.3. OBD II STANDARD FAULT CODES....................- 107 -...

- Page 102 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 9.1 General information The UM motorcycles “Xtreet 125 EFI” have a “Mikuni” EFI system with the following components: 9.2.1. ECU (Engine Control Unit) 9.2.2. Electric fuel pump 9.2.3. Throttle position sensor 9.2.4.

- Page 103 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI Note: To installation of Android version, Searching iOBD2 on Google play, download the app and install. • Installation to OBD II port Plug the iOBD2 adapter into the OBD II...

- Page 104 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI • Wait for “Connection Successful” logo to appear Note: With the XTOOL adapter you can only use some of Diagnostic and Dashboard options. • Trouble codes • You can use “Diagnostic” to scan and read all failure codes (Trouble Code).

- Page 105 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI • Main failure codes for REN II EFI system: P0115 – 119 ENGINE COOLANT TEMPERATURE SENSOR FAILURE P0120 – 124 THROTTLE POSITION SENSOR FAILURE P0130 – 135 OXYGEN SENSOR FAILURE P0261 –...

- Page 106 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI • Live data In Diagnostic you can use “Live Data” to read in real time some of the sensors of the system. The picture below shown: A. All the sensors to read, Press “Done”...

- Page 107 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI 9.3. OBD II standard fault codes P0115 Engine Coolant Temperature Circuit Malfunction P0116 Engine Coolant Temperature Circuit Range/Performance Problem P0117 Engine Coolant Temperature Circuit Low Input P0118 Engine Coolant Temperature Circuit High Input...

- Page 108 CBF 125 AIR COOLING ENGINE SERVICE MANUAL XTREET 125 EFI P0562 System Voltage Low P0563 System Voltage High P06XX Computer and Auxiliary Outputs P0600 Serial Communication Link Malfunction P0601 Internal Control Module Memory Check Sum Error P0602 Control Module Programming Error...

Need help?

Do you have a question about the CBF 125 and is the answer not in the manual?

Questions and answers