Summary of Contents for Lasermet SWALLOW 4000

- Page 1 Swallow Instruction Manual LASERMET SWALLOW 4000 INSTRUCTION MANUAL THE SWALLOW FILTERED FUME EXTRACTION SYSTEM FOR LASERS Issue 2 CEB00XXX-53-000 Issue 2 30 January 2020...

-

Page 2: Table Of Contents

Swallow Instruction Manual LASERMET SWALLOW 4000 Instruction Manual Contents Safety Warnings ........................3 Concept ..........................4 Main Components ....................... 4 System Description ...................... 5 Installation .......................... 6 Filter Installation ......................7 Wiring ..........................8 Electrical Wiring Connections ..................9 Operation .......................... 10 Maintenance ...................... -

Page 3: Safety Warnings

Swallow Instruction Manual Safety Warnings This device is intended to be used as part of a safety system which may be used to protect personnel and equipment from possible injury, damage, or loss. As such it must be installed and wired according to these instructions and tested by suitably qualified persons. -

Page 4: Concept

Full support, design and installation is available from Lasermet, please contact us for any queries. Contact details are given at the end of this manual. -

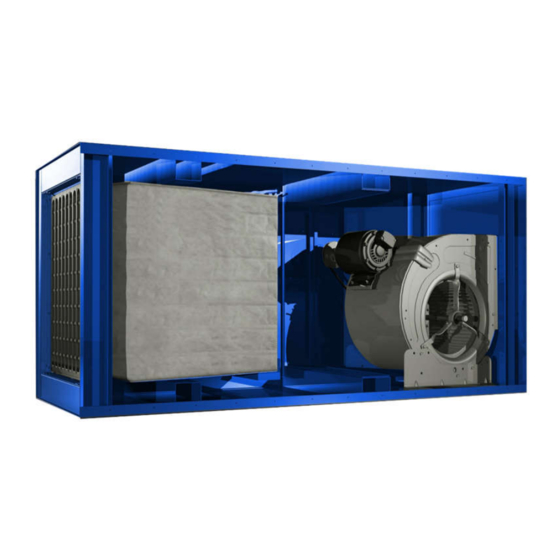

Page 5: System Description

Typical Air changes per hour Lasermet’s standard cabin measures 25’3” x 16’5” x 11’6” or 8 x 5 x 3.5m which is 140m . For this size of cabin, the Swallow Fume Extraction System will provide 50 air-changes per hour. -

Page 6: Installation

Swallow Instruction Manual Internal air filter holding assemblies include gaskets which prevent air bypass and ensure that all of the air is being treated by the system. Primary and secondary air filters are installed from this end of the unit. Installation of replacement filters does not require tools or fasteners. Filter options: Air filters can be selected specific to the volume and type of contaminant concerned. -

Page 7: Filter Installation

Swallow Instruction Manual 3.1 Filter Installation Warning: Do not install or replace filters with the system operating. Do not operate without the proper filters installed. The system is designed to accommodate up to (2) stages of filtration. Filters are installed in the inlet FastFrame holding frame. -

Page 8: Wiring

Swallow Instruction Manual Pre-filter Installation (Optional) Only use 2” or 4” depth cardboard frame prefilters. 1. Use the same method as previously described to install prefilter in front of primary filter. 2. Push and seat the filter against the primary filter. (Note: minor prefilter frame deflection is expected.) Wiring The system is completely factory wired to a junction box located on the top panel. -

Page 9: Electrical Wiring Connections

Swallow Instruction Manual 4.1 Electrical Wiring Connections CEB00XXX-53-000 Issue 2 30 January 2020 Page 9 of 12... -

Page 10: Operation

When placing an order for replacement filters, provide Lasermet with the serial number and part number. This information can be found on the system label on top of the housing next to the inlet power junction box. -

Page 11: Specifications

Throw (distance @ 100 fpm) 100 ft Dimensions are approximate. Values given as ‘typical’ are average values measured across a number of samples and are not guaranteed. Lasermet reserve the right to alter any specification without prior notice. Warranty Lasermet provide a 12-month warranty for defects in materials and manufacture, from the date of installation or delivery. -

Page 12: Contact Details

Swallow Instruction Manual Contact Details Lasermet provide a full range of laser interlock equipment including interlock switches, illuminated warning signs, laser shutters, entry keypads with built-in fail-safe override timer, door locks, external power supplies etc. which can be interconnected to provide a complete system. We also supply equipment and consultancy covering all aspects of laser safety.

Need help?

Do you have a question about the SWALLOW 4000 and is the answer not in the manual?

Questions and answers