Subscribe to Our Youtube Channel

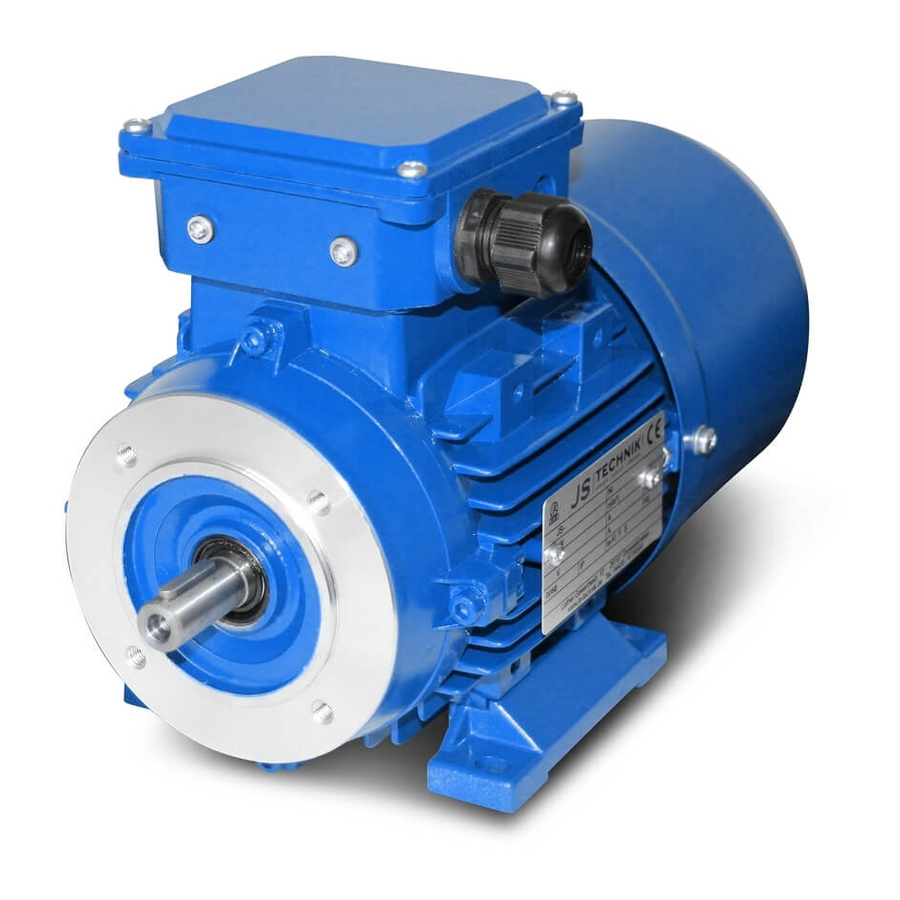

Summary of Contents for JS Technik MS Series

- Page 1 JS-Technik GmbH - Lether Gerwerbestrasse 10 - 26197 Großenkneten - www.js-technik.de...

-

Page 2: Table Of Contents

Table of contents Table of contents ............................. 2 Safety instructions ........................... 3 1.1. Validity ............................. 3 1.2. Qualification of the personnel ....................3 1.3. Basic safety rules ........................3 1.4. Electrical potential ........................3 1.5. Mechanical movement ......................4 1.6. Increased surface temperatures ..................... -

Page 3: Safety Instructions

1. Safety instructions Please read the operating manual carefully before you start with commissioning. Consider the JS-Technik following warnings avoid personnel injuries machinery failures. GmbH assumes no responsibility or guarantee for damage and consequential damage caused by failure to observe the operating instructions. 1.1. -

Page 4: Mechanical Movement

DANGER Motor restart If the control voltage is applied or the speed setpoint is stored, the motor restarts automatically after a power failure. 1.5. Mechanical movement Body parts which come into contact with rotating parts, can be injured. Clothes, jewellery, and similar objects can be caught and pulled into the motor. -

Page 5: Unauthorized Usage

Unauthorised usage 2.1. In particular, the following uses of motors are prohibited and can lead to machinery failure: • Operating the motor with imbalance, for example, caused by dust deposits or icing. • Resonance operation, operation with strong vibrations, transmitted from the environment to the motor. -

Page 6: Electrical Connection

• Ensure even support, precise alignment in case of direct coupling and use of thread sizes specified in EN 50347 for motor feet and flange mounting. • Provide a vibration-free environment. Avoid build-up resonances with rotation frequency and the double frequency of the power supply. •... -

Page 7: Connection Of Lead Out Cables

The connection must be made in such a way that a permanently secure electrical connection is maintained (no protruding wire ends). Suitable cable lugs must be used for the connections of all main cables. A safe protective conductor connection must be made. Tightening torques can be found in Table 2. -

Page 8: Tightening Torques

must be checked. If necessary, change the direction of rotation by exchanging the connection of two phases. Before closing the terminal box it is essential to check that: • The connection is done according to the connection diagram • All terminal box connections, mounting parts and grounding connections are firmly tightened •... -

Page 9: Maintenance

Tightening torques for the metal and plastic cable glands for the direct attachment to the machine and other glands (such as reducers) shall be in accordance with Table 5. Cable gland Metal ±10% Nm Plastic ±10% Nm M16 x 1,5 M20 x 1,5 M25 x 1,5 M32 x 1,5... -

Page 10: Initial Inspection

7.1. Initial inspection The following tests are carried out when the machine is at a standstill: • Check the foundation. Following tests are carried out when the machinery is running: • Check the electrical characteristics. • Check the bearing temperatures. •... -

Page 11: Lubrication

7.3 Lubrication For motors with open rolling bearings (current-insulated or "reinforced" NU bearings), the relubrication intervals must be observed in accordance with the table shown . *= For motors of size 56 to 180, closed bearings with lifetime lubrication are used! First - Filling Ball bearing Re-Lubrication-... -

Page 12: Bearing Sizes Ip23 Motors

First - Filling Ball bearing Re-Lubrication- Ball bearing Re-Lubrication- Type Power Pole Intervalls (B-Side) DE/NDE Quantity DE/NDE (A-Side) Bearing clearance:C3 Hours Bearing clearance:C3 Gram Gram 6309 6209 SEV-160M6 6309 6209 SEV-160L6 6311 6211 SEV-180L6 18,5 6312 U312 6212 6500 32/32 25/25 SEV-200L6 6312 / NU312... -

Page 13: Auxiliary Equipment

Re-greasing on a running machine as well as downtime re-greasing is possible. Following information should be noted: • When the motor is running, make sure that the grease outlet, grease inlet, and channel are open. Inject the intended amount of grease into the bearing and let the machine run for 1 – 2 hours. -

Page 14: Troubleshooting

9. Troubleshooting Table 9 addresses the causes of errors that may occur and the action to be taken. All procedures are only allowed to be carried out by qualified personnel using suitable tools and instruments. For further information please contact JS-Technik GmbH. Failure Cause Actions... -

Page 15: Construction Of Motors

10. Structure of the motors Beschreibung Ersatzteile / description of spare parts Aluminiumgehäuse / aluminum housing Bezeichnung description Serie MS Serie ML Stator-housing Statorgehäuse A-Lagerschild Drive end shield Dichtung für Klemmenkasten Gasket for terminal box Klemmenkasten Terminal box Klemmenkastendeckel Terminal box cover Dichtung für Klemmenkastendeckel Gasket for terminal box cover Mounting feet for stator housing... - Page 16 Beschreibung Ersatzteile / description of spare parts Aluminiumgehäuse / aluminum housing Der Hersteller behält sich Änderungen vor. The manufacturer reserves the right to make changes. JS-Technik GmbH - Lether Gerwerbestrasse 10 - 26197 Großenkneten - www.js-technik.de...

- Page 17 Beschreibung Ersatzteile / description of spare parts Graugussgehäuse / cast iron housing Bezeichnung description Serie M Serie MQ A - Lagerschild Drive end shield B – Lagerschild Non drive end shield Screw for end shield / flange Schrauben für Lagerschild bzw. Flansch B5 –...

- Page 18 Beschreibung Ersatzteile / description of spare parts Graugussgehäuse / Cast iron housing Der Hersteller behält sich Änderungen vor. The manufacturer reserves the right to make changes. JS-Technik GmbH - Lether Gerwerbestrasse 10 - 26197 Großenkneten - www.js-technik.de...

-

Page 19: Load Capacity Curve

11. Load capacity curve Load capacity curve of JS-Technik electric motors in frequency inverter operation without forced cooling fan Nominal torque in % JS-Technik GmbH - Lether Gerwerbestrasse 10 - 26197 Großenkneten - www.js-technik.de... -

Page 20: Declaration Of Conformity

EU Declaration of Conformity JS-Technik GmbH Manufacturer: Lether Gewerbestrasse 10 26197 Großenkneten Address: Low voltage asynchronous motors, Product name: single phase motors, gear motors 1) Motors that comply with Guidline 2009/125/EC and Regulation (EU) No. 4/2014 are given the identifier IEx-, before the series designation where x = 1,2,3,4 (according to EN 60034-30-1:2014).

Need help?

Do you have a question about the MS Series and is the answer not in the manual?

Questions and answers