Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ddtop ULB

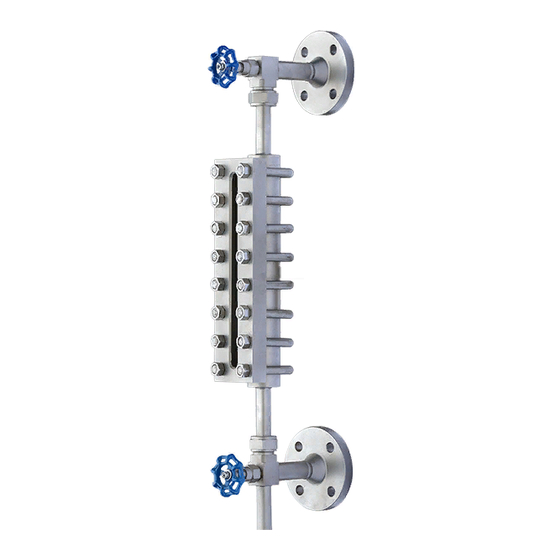

- Page 1 GLASS PLATE LEVEL GAUGE Operation Manual WWW.DDTOP.COM 1 / 10...

- Page 2 If the instructions are not followed, the protection provided by the meter may be destroyed. Trademark, Copyright and Restriction Instructions Dandong Top Electronics Instrument (Group) Co.,Ltd.®, Dandong Top Pump Co., Ltd.®, DDTOP® are registered trademarks of the company. The performance specifications of the meter are effective as of the date of publication and are subject to change without notice.

-

Page 3: Table Of Contents

7 Debugging ..................................7 8 Fault Analysis and Elimination ..........................8 9 Maintenance ..................................8 9.1 Warning ................................8 9.2 Disassembly ..............................8 9.3 Cleaning ................................8 9.4 Assembly ................................ 9 10 Product Certification ..............................10 WWW.DDTOP.COM 3 / 10... -

Page 4: Safety Tips

1. Safety Valve 2. Fasteners,including Bolt and Nut Washers 3. Pressure Plate (Gland) 4. Cushion 5. Glass Plate 6. Seal 7. Body 2.2 Operating Principle In accordance with the principle of communicating vessels.Through the built-in sight glasses,the WWW.DDTOP.COM 4 / 10... -

Page 5: Packaging

3.2.2 Heating steam jacket joints:R3/8 or on request 3.2.3 Flange:HG/T20592-2009,HG/T20615-2009 or on request 4 Dimensional Schematic -Figure 2 If the order is required to be a special size, the actual size will prevail. Frost-proof Non-blind Glass Plate Level Gauge WWW.DDTOP.COM 5 / 10... -

Page 6: Unpacking And Inspection

No Blind Zone Glass Plate Level Gauge Figure 2 Dimensional Schematic 5 Unpacking and Inspection 5.1 Unpacking Inspection Notice 5.1.1 Check whether the product nameplate (Figure 3) is consistent with the supply list information. Figure 3 Product Nameplate WWW.DDTOP.COM 6 / 10... -

Page 7: Check Content

6.2.2 Install the liquid level timing, the level of the level gauge flange must be perpendicular to the horizontal plane 7 Debugging - Figure 4 Figure 4 Debugging WWW.DDTOP.COM 7 / 10... -

Page 8: Fault Analysis And Elimination

9.2.3 After removing the bolts, remove the pressure plate, glass plate and gasket in turn. 9.3 Cleaning 9.3.1 Do not use damaged glass plates, used gaskets, mica pads. 9.3.2 Carefully clean the sealing surface so that the surface is clean and free of debris and scratches; WWW.DDTOP.COM 8 / 10... -

Page 9: Assembly

9.4 Assembly 9.4.1 Assembly order of glass plate level gauge 9.4.1.1 Assembly order of transparent glass plates 9.4.1.2 Assembly order of reflective glass plates 9.4.2 Preloading order of studs WWW.DDTOP.COM 9 / 10... -

Page 10: Product Certification

9.4.3 Stud torque value Nominal Pressure Pound·Foot Newton·Meter PN<40 40≤PN<100 100≤PN<160 PN≥160 10 Product Certification WWW.DDTOP.COM 10 / 10...

Need help?

Do you have a question about the ULB and is the answer not in the manual?

Questions and answers