Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Trillium SARASIN-RSBD 78 Series

- Page 1 78 SERIES Installation, Operation, Maintenance Manual...

-

Page 2: Table Of Contents

78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ CONTENT SAFETY INSTRUCTIONS ..........................3 SAFETY PRECAUTIONS ........................... 4 WARRANTY INFORMATION ..........................5 TERMINOLOGY ..............................6 GENERAL ADVICE ............................7 5.1 RESPONSIBILITIES ........................7 5.2 IDENTIFICATION PLATE ....................... 7 5.3 PILOT SPRING ..........................8 5.4 STORAGE............................ - Page 3 78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ SAFETY SIGNS AND LABELS Signs or labels are included throughout this document. These signs or labels communicate the following messages: • The level of hazard seriousness • The nature of the hazard • The consequence of human or product interaction with the hazard •...

-

Page 4: Safety Instructions

Consequently, anyone who uses a procedure and/or tool, which is not recommended by Trillium Flow Technologies , or deviates from Trillium Flow Technologies recommendations must be thoroughly satisfied that neither personal safety nor equipment safety will be jeopardized by the method and/or tools which have been selected. -

Page 5: Safety Precautions

• Never modify or change the valves, especially when they are under pressure. It is essential that you inform Trillium Flow Technologies in All instances if any machining of parts is to be considered. Deviation from critical dimensions can adversely affect the performance of a safety valve. -

Page 6: Warranty Information

Trillium Flow Technologies warrants that its products (including performance) and work will meet the specifications of the customer’s Purchase Order. If any issue arises whilst operating the product, the customer should inform Trillium Flow Technologies as quickly as possible. A return to the original plant should then be considered in order for Trillium Flow Technologies to inspect the product. -

Page 7: Terminology

78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ 4 TERMINOLOGY For the purpose of this manual, the following abbreviations, definitions and terms apply ACCUMULATION The pressure increase over the maximum allowable working pressure of the vessel, expressed in pressure units or as a percentage of maximum allowable working pressure (MAWP) or design pressure. -

Page 8: General Advice

The recommended practices indicated within this manual must be respected to prevent any potential damage to goods. It is important that all points of advice are followed closely and are implemented by suitably qualified personnel. Trillium Flow Technologies disclaims all responsibility for maintenance operations which may be... -

Page 9: Pilot Spring

• Above than +5% adjustment can cause permanent deformation to the spring. • Below than -5% adjustment can cause the pilot not to open fully. • For more than +/- 5% adjustment you must contact Trillium Flow Technologies Sarasin-RSBD Aftersales Department. -

Page 10: Storage

78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ 5.4 STORAGE ATTENTION ATTENTION Never lift the valve Make sure the valve is not horizontally, or hook to the dropped and does not receive lifting lever or the spring. strikes. Always lift by using the lifting eyes or sling. -

Page 11: Series Basics

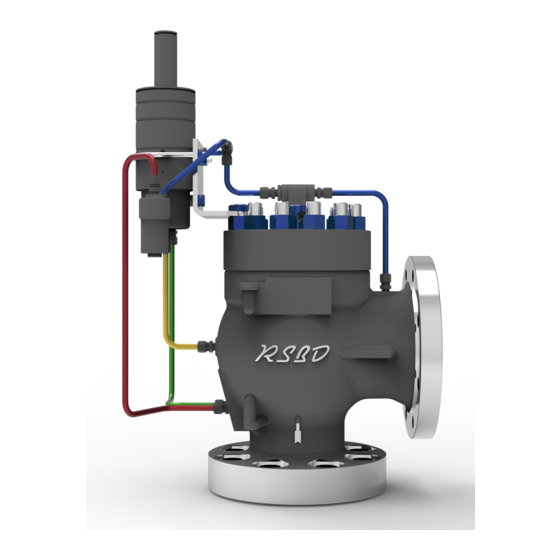

78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ 76 SERIES BASICS 6.1 DESCRIPTION Materials for standard applications, high temperature, low temperature and corrosivfluids. The 76 series is a versatile pressure relief valve. The design of 76 series particularly fit together extreme conditions as Cryogenic, Liquefied Natural Gas and Steam. - Page 12 78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ Part SPARE Part PARTS N° Name Body Cover Seat Back Up Ring Guide Ring Guide Piston O- Ring Soft Seat Disc Disc Stud O-Ring Seat O-Ring Return Spring Piston Retainer Washer Retainer Screw FIGURE 2 Note : Spart parts chapter 11.

-

Page 13: Installation

78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ 7 INSTALLATION 7.1 GENERAL DANGER WARNING CAUTION CAUTION Never face the outlet of a Be aware that the Protect against high noise Helmets and gloves must valve when it is environment might be levels which occur during be worn to prevent any discharging as this may... -

Page 14: Outlet Piping

78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ 7.3 OUTLET PIPING The safety valve must not support either the weight or the installation stresses of the outlet piping. The backpressure should be reduced by using outlet piping with a nominal diameter of at least one size greater than the nominal diameter of the safety valve outlet flange, together with large radius elbow. - Page 15 78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ DA (mm) DB (mm) DC (mm) FIGURE 3 It is necessary to use a torque wrench to tighten the inlet and outlet flange bolting. 1. A check should be made that the gasket is centered on the flange 2.

-

Page 16: Options

78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ 7.5 OPTIONS 7.5.1 REMOTE SENSE • Safety valve will respond to actual system pressure conditions. • Eliminates undesirable cycling due to excessive inlet pressure losses. • Improves safety, under adverse operating conditions. This optional feature permits the pilot to sense system pressure at a location that most accurately reflects the actual operating pressure of the protected system. -

Page 17: Field Test Connection

Its connection is also 1/4” NPT and it is fitted just before the Field Test Connection (between the Field Test Connection and the Test Gauge on the previous sketch). Trillium Flow Technologies pilot operated safety valves shall be pressurized at 90% of the set pressure in order to perform this test. -

Page 18: Back Flow Preventer

78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ 7.5.3 BACK FLOW PREVENTER • Prevents accidental reverse flow through safety valve. This option, sometimes called a ‘vacuum block,’ prevents a pilot operated safety valve from reverse flow, when sufficient vacuum is present at the inlet flange. The backflow preventer also prevents reverse flow when the pressure at the outlet flange (superimposed back pressure) is greater than the current system pressure. -

Page 19: Outdoor Installation

78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ 7.6 OUTDOOR INSTALLATION A safety valve which is installed outdoors must be protected against any inclement environmental conditions to ensure that it will provide the highest level of safety and will operate in the most effective & responsive manner. If the safety valve is exposed to hazardous weather conditions, ingress of dirt or other foreign matter or any extremes of temperature conditions, please ensure that: •... -

Page 20: Maintenance

No particular tool is required for the maintenance operations on the main valve of the 76 series valve. Regarding the pilot, a tool kit is recommended to ease the lapping and the re-assembly of disc in the pilot body. Maintenance may be performed without taking the valve off line. Please contact Trillium Flow Technologies Flow Technologies SarasinRSBD aftersales team in the event of any uncertainty. -

Page 21: Disassembly

78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ 8.1 DISASSEMBLY Separate pilot and water tank (if any), support and tubing. TAKE CARE OF THE TUBING! (For the disassembly, assembly of the pilot and the testing part, please refer to the following manuals: »... - Page 22 78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ • Remove the cover (02) • Remove the return spring (46) www.trilliumflow.com...

- Page 23 78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ • Screw a threaded pin in the piston (56) according to the table bellow to take the piston off. Be careful to keep the piston straight while taking it off to avoid droping the guide ring (09) Orifices Thread –...

- Page 24 78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ • Remove the guide (09) from the body (01) O-Ring (40) • Remove the seat (06). Be careful not to forget the seat O-ring (43) www.trilliumflow.com...

- Page 25 78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ • MAIN VALVE PARTS INSPECTION & MAINTENANCE 8.1.1 GENERAL RECOMMENDATIONS We recommend to carefuly stock the disassembled valves per serial number not to mixup parts during inspection and maintenance. Changes from one valve part to another can be invisible to the eye and may compromit perfect valve operation during its whole life cycle.

- Page 26 78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ • Main valve piston (12) Inspect the external diameter of the piston part. It shall not have any scratches or be galled. If this diameter is damaged carefuly check the sliding rings. They might be damaged. Inspect the dynamic seal seating surface. Roughness of the seating surface of the nozzle shall be Ra 0.4µm (16 RMS).

-

Page 27: Main Valve Re-Assembly

78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ 8.2 MAIN VALVE RE-ASSEMBLY 8.2.1 PROCEDURE • Parts to be assembled should be absolutely clean, degreased and dried. • We recommend greasing all thread and contacting parts except guiding piston/guide and • seat between nozzle and disc. Use grease according to service (oxygen, food…) •... -

Page 28: Maintenance Tools

78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ MAINTENANCE TOOLS • Lapping tools and LAMPLAN diamond paste (1.213, 3.213, 6.213) • Lifting eyes • Psiton removal and assembly tool • Pilot disc re-inserting spindle (included in pilot tool kit for DCS) •... -

Page 29: Troubleshooting

½ blowdown value The valve chatters The valve is oversized Investigate what are the real process condition and check the sizing with Trillium Flow Technologies The upstream pressure drop is too Sensing the pressure remote instead of through high the sensing ring. -

Page 30: Spare Parts

Such work must be carried out by a skilled technician. The Trillium Flow Technologies Group offers trainings and education programmes to cover all areas of maintenance and repair. Please consult your nearest Trillium Flow Technologies representative for more details. To perform basic maintenance tasks within the shortest possible timeframe, it is recommended that class “A” spare parts are purchased at the same time as new valves. -

Page 31: Genuine Parts

78 SERIE SAFETY RELIEF VALVE SARASIN-RSBD ™ 14 GENUINE PARTS The use of spare parts which are not obtained from a genuine Trillium Flow Technologies source or a Trillium Flow Technologies accredited company exposes product, plant and personnel to high risk.

Need help?

Do you have a question about the SARASIN-RSBD 78 Series and is the answer not in the manual?

Questions and answers