Summary of Contents for KegLand Cannular Compact KL10757

- Page 1 Cannular Compact Canning Machine Instruction Manual Cannular Compact Manual Canning Machine Instruction Manual KL10757 KegLand Distribution PTY LTD www.KegLand.com.au www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 1 of 27...

- Page 2 NEAR ANY MOVING PARTS. THERE IS A RISK OF SERIOUS INJURY OR DAMAGE TO THE MOTOR IF THE CANNULAR IS PLUGGED IN WHILE MAKING ANY ADJUSTMENTS. WARNING AVOID CONTACT OF ANY ELECTRICAL COMPONENTS WITH LIQUID. www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 2 of 27...

-

Page 3: Getting Started

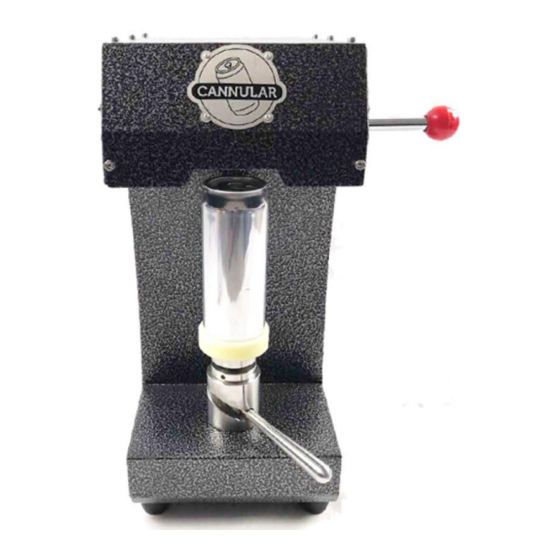

Immediately upon unpacking the Cannular inspect the unit for any signs of damage and do not operate the Cannular if any damage is observed. The Cannular has been designed to suit cans available from KegLand and comes standard with a B64 chuck which is compatible with cans available from KegLand. The Manual Cannular can be setup to seam 330mL or 375mL cans by changing the table spacer. - Page 4 Cannular Compact Canning Machine Instruction Manual Your Cannular is calibrated and set up at the factory to seam KegLand 500mL B64 cans (KL05449, KL18517 and KL15684), however, due to an extended transit time it may have shifted out of specification during its journey. Before making any adjustments to the seamer follow the following initial start-up instructions: 1.

- Page 5 We recommend customers check the specifications on the seam every 50,000 cans or once a year to ensure the cans remain within allowable tolerances. Table Spacer Turn Table Support Coupling Nut Turntable Lever www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 5 of 27...

- Page 6 Cannular Compact Canning Machine Instruction Manual Power Switch Operation Lever Op x-axis Op x-axis bump stop bump stop Op y-axis Op y-axis adjustment nut adjustment nut Op Roller Op Roller Chuck www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 6 of 27...

- Page 7 The Cannular is setup out of the box with a chuck that is suitable for B64 can ends. This chuck is compatible with cans available from KegLand. If you wanted to use a non-KegLand can and can end then you will need to adjust the rollers and change the chuck to suit the specific can end you are using.

- Page 8 Make sure to tighten the grub screws very well to ensure the Cannular stays in specification. Push as far up as possible Tighten grub screws www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 8 of 27...

- Page 9 Turn the table support counter-clockwise to raise and clockwise to lower the turn table support. www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 9 of 27...

- Page 10 When putting these back into place ensure the concave parts of the bearing assembly are facing towards the ball bearings. www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 10 of 27...

- Page 11 (see right). If the buckling occurs on the second operation then please check your can is being raised straight up and completely concentric with the chuck. www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 11 of 27...

- Page 12 (turn clockwise) the coupling nut on the base of the turn table. You can apply force in the opposite direction to the lever to prevent it raising as you tighten the coupling nut. 3. Check the can now lifts concentrically www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 12 of 27...

- Page 13 3. Adjust the position of the turn table so that the can is completely concentric with the chuck when it is raised. 4. Once you are satisfied with the position of the turn table do up the three bolts with the Allen key www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 13 of 27...

- Page 14 Always adjust the gap “Y” first, as gap “X” will change any time you change gap “Y”. Set the 1 Op Roller height (y-axis) 1. Unplug the power from the machine 2. Hold the lever in the 1 position while adjusting the 1 Op Roller height. www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 14 of 27...

- Page 15 To ensure the “Y” gap is measured on the flat face of the roller you may need to increase the x-gap slightly such that the curved face is further away from the chuck. www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 15 of 27...

- Page 16 3. Insert a 5mm Allen key into the socket of the bump stop adjustment screw and adjust the amount of thread showing to change the 1 Op roller gap “X” www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 16 of 27...

- Page 17 2 Op roll, ensuring that adjustments are made when the lever is held in the 2 position when adjusting the 2 operation roller. www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 17 of 27...

- Page 18 Cannular Compact Canning Machine Instruction Manual The gap “Y” on the 2 Op Roll should be 1.35mm +/- 0.05mm The gap “X” on the 2 Op Roll should be 0.3mm +/- 0.1mm www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 18 of 27...

- Page 19 (actual overlap, seam width and seam length) are within their specified ranges for forming a high pressure, leak free seam. www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 19 of 27...

- Page 20 The x and y measurements of the 2 operation roller effects both the seam width and length. www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 20 of 27...

- Page 21 Hence, it is important that both rollers are at their respective correct positions for the seamer to be in specification. IMAGE 1 – 1 Operation IMAGE 2 – 2 Operation www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 21 of 27...

- Page 22 You should have two individual cans that look like this below: LEFT: First operation only (we will refer to this as Can A) RIGHT: First and second operation completed (we will refer to this as Can B) www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 22 of 27...

- Page 23 WARNING: Please take appropriate safety precautions when using power tools. CAN B CAN A www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 23 of 27...

- Page 24 If you determine that the actual overlap between the can body and can end is less than 0.4mm following the first operation, make sure that your 1 operation roller is in the correct position. www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 24 of 27...

- Page 25 2 operation roller is not in its correct position. Hence, both actual overlap from the first operation and overlap following second operation should be assessed. www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 25 of 27...

- Page 26 If the 2 operation roller is too close to the chuck it can cause springback which can result in the seam width becoming thicker. www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 26 of 27...

- Page 27 If the seam is too long it can result in the actual overlap separating and the seam no longer sealing. www.KegLand.com.au Last Updated 4/03/2021 2:06 PM Page 27 of 27...

Need help?

Do you have a question about the Cannular Compact KL10757 and is the answer not in the manual?

Questions and answers