Table of Contents

Advertisement

Gruppo Aturia

Gruppo Aturia

20060 Gessate (MILANO), ITALY / Piazza Aturia, 9

Tel. +39-0295423200 /Fax +39-0295423202

www.gruppoaturia.com

LTK0E01D

AUDOLI &

ARIS

BERTOLA

CHIAPPA

S.p.A.

05/2017

C

E

N

T

C

E

N

I

N

S

T

R

U

C

I

N

S

T

R

U

C

1

M

U

L

T

I

S

T

M

U

L

T

I

S

T

R

I

F

U

G

A

L

P

U

T

R

I

F

U

G

A

L

P

U

T

I

O

N

M

A

N

U

T

I

O

N

M

A

N

U

T

K

T

K

A

G

E

A

G

E

M

P

S

M

P

S

A

L

A

L

Advertisement

Table of Contents

Summary of Contents for ATURIA TK

- Page 1 Gruppo Aturia AUDOLI & ARIS BERTOLA CHIAPPA Gruppo Aturia S.p.A. 20060 Gessate (MILANO), ITALY / Piazza Aturia, 9 Tel. +39-0295423200 /Fax +39-0295423202 www.gruppoaturia.com LTK0E01D 05/2017...

-

Page 2: Table Of Contents

CONTENTS CAP.1 GENERAL DESCRIPTION 1.1 Construction Features 1.2 Fields of applications 1.3 Noise levels CAP.2 TRANSPORT AND STORAGE 2.1 Transport 2.2 Site installations 2.3 Storage CAP.3 GENERAL SAFETY INSTRUCTIONS 3.1 General Instructions 3.2 Precautions during Operation 3.3 Residual Risks 3.4 In case of emergency CAP.4 INSTALLATION 4.1 Installation 4.2 Alignment... - Page 3 Remember that TK pumps are potentially dangerous to the person and to the things due to the presence of : - High speed rotating parts...

-

Page 4: Fields Of Applications

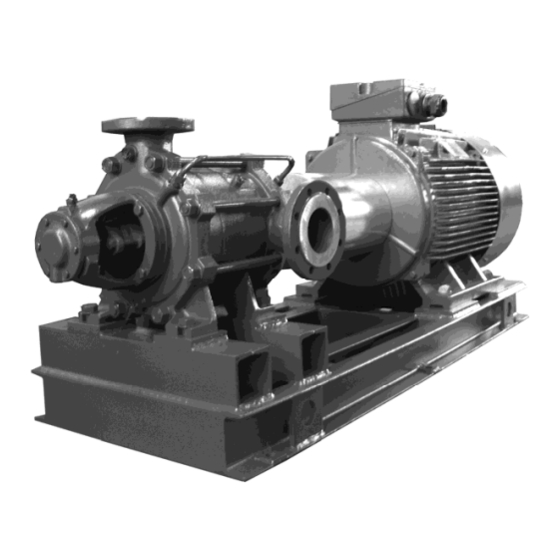

- Month/ year of construction Shaft speed (Rpm) TK are multistage pumps with more elements in line, and they are divided into perpendicular planes to the rotation axis. Sealing between the different elements is ensured by O-rings tightened by sturdy outer tie rods. -

Page 5: Noise Levels

1.3 Noise levels The following table reports the noise level produced by TK pumps running within their operating limits and installed according to the instructions given in this manual. (Average values measured at 1 meter from the pump and elaborated according to ISO curve A - standard R 1680). -

Page 6: Transport

TRASPORT AND STORAGE 2.1 Transport Before transportation, please perform the following checks: -Weight of pump/motor group -Overall dimensions of pump/motor group -Suitability of lifting points The pump can be dispatched in the following ways: A) Single pallet B) Wood box The pump should be transported with equipment fit for its weight and for the shape of its packing case (see side pictures). -

Page 7: Storage

2.3 Storage The deivered pump is generally suitable for immediate installation. STORAGE FOR A PERIOD OF LESS THAN 3 MONTHS : - Store the pump in a dry and sheltered area. - Check that ambient temperature never falls below 5°C. - It is recommended that the pump shaft is rotated at regular intervals ( every 30 days );... -

Page 8: General Instructions

The pump(s) should be used only for the applications specified in par. 1.2. Recommended operational limits must be strictly observed. In case of applications not specified on this manual, please contact ATURIA to check for pump suitability, installation safety and pump life. 3.2 Precautions during operation Never put your hands or any kind of object into pump openings where the shaft rotates (see side picture). -

Page 9: Residual Risks

3.3 Residual risks Inobservance of the safety instructions here reported or improper use of the pump may result in heavy damage to things and/or injuries to the person. Always keep to the following directions : - Don’t kick the pump - Don’t damage the pump by wrong handling - Don’t pressurize the pump beyond recommended limits - Avoid dry running, operation at lower capacity than allowed, or running with closed gate... -

Page 10: Installation

INSTALLATION 4.1 Installation For what concerns pump handling at the installation site, please refer to section 2.1. The pump/motor group, coupled on a single steel-sections baseplate, must be properly fastened to its concrete slab in which the foundation bolts have been previously bedded. The group should be installed on a levelled plane. -

Page 11: Alignment

4.2 Alignment After positioning the pump unit on the foundation and connecting the pipes, it is necessary to align it with due precision before starting. To this purpose, remove the coupling guard and measure the concentricity and the parallelism of the half coupling joints with a ruler and a thickness gauge. Place the ruler in positions 1-2-3-4 ( see below picture ) and check radial offset “a”... -

Page 12: Startup

5.1 Startup Before starting the pump it is necessary to fill it with water through the suited filling hole, located on suction casing. Once the pump has been primed, close delivery gate valve and start the pump for a fraction of a second to check rotation direction. -

Page 13: Ordinary Maintenance

MAINTENACE 6.1 Ordinary Maintenance Once started the pump, check it as frequently as possible by means of plant instruments like pressure gauges, vacuum meters and ammeters. The pump needs normally no maintenance, except a periodical check to: - Seal operation (either mechanical or packing) - Bearing operation - Periodical renew of lubricant grease in bearings PACKING SEAL... -

Page 14: Pump Stop

Check bearing housing temperature: it should never exceed 70°C. If this happens, check group alignment or remove bearing housing cover as the cause might be an excessive amount of grease or a failed bearing. If a danger of frost exists, drain the pump completely during idle periods by unscrewing the draining plug (see picture aside). -

Page 15: Pump Disassembly

DISASSEMBLY Disassembly and reassembly operation must be carried out by skilled personnel only. Before any intervention on the pump it is necessary to: - Switch the voltage off - Close pump suction and delivery gate valve - If the pump transports hot liquids let it cool at ambient temperature - Discharge pump bowl from pumped liquid through a discharge hole. - Page 16 Check conditions of impellers (2200), wear rings (1500), impeller rings (if any 2300), spacer sleeves (2461) and bearings (3011-3012), which must be without linings or, on the contrary, must be replaced. Diametric clearance between bowl wear ring and impeller collar, or between bowl wear ring and impeller wear ring (if any) must be as indicated in the following table: CLEARANCE REFERENCE MINIMUM DIAMETER...

- Page 17 For reassembly proceed in the opposite direction disassembly. 8.1 PUMP REASSEMBLY Lock the radial roller bearing (3012) on the shaft (2110) using the circlip (6545), the retaining ring, split (2531) and the relative sleeve (2483), insert the bearing in the bearing housing (3200) and close the bearing cover (3261).

- Page 18 SPARE PARTS For a faster processing of Your order, when ordering spare parts please specify: - Pump type -.Pump serial number -.Part name and number as listed on sectional drawing. Pump type and serial number are printed on the nameplate. For recommended spare parts see part list (EKY0102 –...

- Page 19 FAULT FINDING CHART PROBLEM PROBABLE CAUSE REMEDY 1.1 Pump and suction pipe not well primed, with Prime again pump and THE PUMP GIVES air trapped in the system suction pipe NO WATER 1.2 Air enters the system through suction pipe open taps or through foot valve not enough Correct installation submersed...

- Page 20 PROBLEM PROBABLE CAUSE REMEDY THE SEAL LEAKS Replace (See section 5.1 Worn seal EXCESSIVELY Repair the pump - see 5.2 Worn sleeve at seal position section 8. Repair the pump - see THE PUMP VIBRATES 6.1 Unbalanced rotating assembly chapter 8 AND IT IS NOISY 6.2 Worn pump bearings See chapter 8...

- Page 21 Forces – (daN) Moments –(daN.m) TYPE FLANGE Σ Σ Σ Σ SUCTION TK25-40 DELIVERY SUCTION TK32-50 DELIVERY SUCTION TK40-65 DELIVERY SUCTION TK50-80 DELIVERY SUCTION TK65-100 DELIVERY SUCTION TK80-125 DELIVERY SUCTION TK100-150 DELIVERY SUCTION TK125-150 DELIVERY SUCTION TK150-200 DELIVERY SUCTION TK200-250 DELIVERY SUCTION TK250-300...

-

Page 22: Decommissioning And Dismantlement

DECOMMISSIONING 10.1: Decommissioning and Dismantlement When the pump will be permanently stopped and dismantled, the various materials composing it should be properly disposed of. It is important to make sure that no residual polluting liquids are trapped within the pump. The materials used in pump construction are: - Steel and cast iron - Aluminium... - Page 24 LTK0E01B 01/2012...

- Page 25 LTK0E01B 01/2012...

- Page 26 LTK0E01B 01/2012...

- Page 28 LTK0E01B 01/2012...

- Page 29 LTK0E01B 01/2012...

- Page 30 LTK0E01B 01/2012...

- Page 31 Section 3 Declaration Noi, Gruppo Aturia S.p.a. /Piazza Aturia,9 /Gessate/ Mi/, dichiariamo che é garantita la conformità ai requisiti essenziali di sicurezza e di tutela della salute della Direttiva Macchine 2006/42/CE. We, Gruppo Aturia S.p.a. /Piazza Aturia,9/Gessate/ Mi/, declare that is in conformity with all the essential health and safety requirements of the Machinery Directive 2006/42/CE.

Need help?

Do you have a question about the TK and is the answer not in the manual?

Questions and answers