Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for AIC WAIKATO Presto Master

- Page 1 Presto Master Copyright©Agricultural Instruments Corp (AIC)

- Page 2 Presto Master 10/11/2016 A message from AIC Agricultural Instruments Corporation (AIC) would like to thank you for purchasing your new Presto Master and accessories. The instrument you purchased will be valuable dairy herd management tool for years to come The Tracker Plus hands-off dairy management system networks with AIC’s “Smart Sensing”...

-

Page 3: Technical Specifications

Presto Master Technical Specifications Physical Specifications Case: Impact-resistant polysulphone with scratch-resistant Lexan ™ front label. Size 4.5” x 6.5” x 2.0”, Weight less than 16 ounces (454 grams). FlowCell: Approved P-1700 Polysulfone materials and 304 stainless steel sensing probes. Shape is a modified elbow, approximately 3” x 2.5” suitable for use with all 5/8” ID milk hose. -

Page 4: Power Supply

Presto Master 10/11/2016 Power Supply Presto Control Outputs: Power Requirement Calculation: To calculate the power requirements take the Cylinder output: 1 form ‘A’ (single pole N/O) solid number of units multiplied by the number of watts state contact up to 0.5A load. - Page 5 To change any of the operating parameters, it is necessary to enter the setup mode. To enter into the setup mode, push both switches at the same time. Once in the setup mode the Presto Master will prompt you through the set-up options.

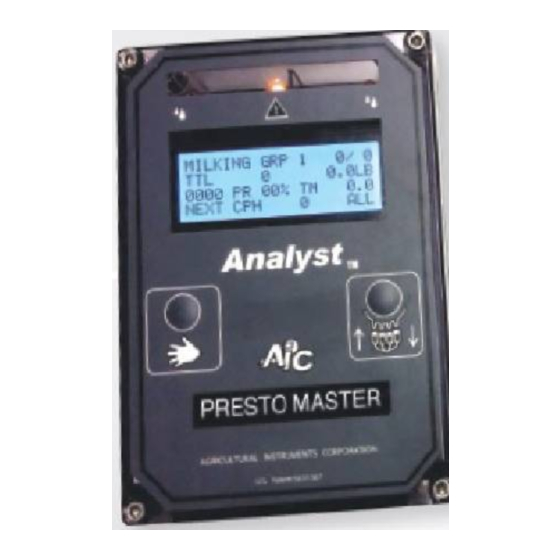

- Page 6 Presto Master 10/11/2016 Analyst Presto Master Control Lamp Operation There are three lamps embedded in the top of the control two red and one yellow. The two red lamps located on the upper corners of the controls provide indications as follows: Right RED LED is on during milking.

- Page 7 Presto Master Presto Master Internal and External Wiring Diagram External Wiring Diagram The following wiring schematics layout three different ways the Analyst Presto Control can be wired. USE DIELECTRIC ON ALL WIRE NUT CONNECTIONS. 2 conductor cable = power in directly from Presto system power supply.

- Page 8 Presto Master 10/11/2016 Internal Wiring Diagram 2 conductor 24 gauge or larger cable = power directly from Presto system NOTICE power supply 2 conductor twisted pair of communication cable w/ shield Power In (directly Com. Cable from wired to the main...

-

Page 9: System Operation

Presto Master System Operation & Milk Yield Calibration System Operation After starting a new system it is important to know there maybe data in the Tracker that is left over from testing the system during manufacturing. Please disregard any information that may appear during start-up. -

Page 10: Set Up Table

Yes / No Automatic claw lift with Herd Tracker Set GI at wash Yes / No Resets all Stalls at Group One Number of seconds Presto Master (PM) Wash Guard Value 30—180 seconds 30 seconds will allow system to switch to wash... - Page 11 Presto Master Factory Effects of Function Range Increments Settings Adjustment Vacuum on Delay 0 - 2.5 seconds 0.5 seconds 1 second Delay to apply vacuum after releasing cylinder Claw Lift Enabled Yes/No/Prep Timer Automatic claw lift with Herd Tracker Calibrate meters to Increase if Analyst over reads.

- Page 12 Presto Master 10/11/2016 Factory Effects of Function Range Increments Settings Adjustment Zero disables the prep timer. The timer starts when the detacher milk (right) switch is pressed. The Presto display shows a countdown number to zero with it is time to attach. Ten seconds prior to actual...

-

Page 13: Network Termination

Network Termination It is necessary to terminate the communications network at the last stall in the parlor and at the Presto Master Control. Therefore, the termination switch must be switched to ON at the last stall in the parlor and at the Presto Master Control. - Page 14 Presto Master 10/11/2016 Presto Master Menu Screens Screen # 1 Milking # / # Next Milking = Currents Status of the Presto Units PR% = Prep Ratio GRP = Group Number TM = Average Milking Time Per Cow # / # = Stalls Milking / Total number of Stalls...

- Page 15 Presto Master Presto Master Menu Screens Screen # 3 Screen Currently In Next Last Milking = 2nd Last milking Next = Takes you to the next screen TL = Total Milk and Average Per Cow CPH = Cows Per Hour CT = Total Number of Cows Milked ALL = All the Cows.

- Page 16 Presto Master 10/11/2016 Presto Master Menu Screens Screen # 5 Screen Currently In # / # Stall PK Peak Temp Stalls Seconds Start / Stop Next Monitor Wash = Wash Screen Next = Takes you to the next screen Stall PK = Stall # that had the highest wash solution Start /Stop= Will start the wash cycle.

- Page 17 NATP = No answer to Poll. A signal is sent from the BLRC = Bad Longitudinal Redundancy Check. Presto Master to the detachers and is not received Counts when a response check character received back. Possible cable or electrical damage was different then expected.

- Page 18 Presto Master 10/11/2016 Agricultural Instruments Corporation Limited Warranty Agricultural Instruments Corporation also referred to as in this document as “The Company” will warrant company product for a period of one year from the date of manufacture against defects in materials and workmanship when installed, serviced and operated in accordance...

- Page 19 Presto Master Disclaimer The products and information in this catalog have been gathered from many sources and every effort has been made to present the information accurately and correctly. However, the information presented in this catalog is solely for the pur-...

- Page 20 Yes / No Automatic claw lift with Herd Tracker Set GI at wash Yes / No Resets all Stalls at Group One Number of seconds Presto Master (PM) will Wash Guard Value 30—180 seconds 30 seconds allow system to switch to wash...

- Page 21 Presto Master User Effects of Function Range Increments Settings Adjustment 0 - 2.5 sec- Vacuum on Delay 0.5 seconds Delay to apply vacuum after releasing cylinder onds Calibrate meters to Increase if Analyst over reads. Use left/right -15 to +15...

- Page 22 Presto Master 10/11/2016 User Effects of Function Range Increments Settings Adjustment Memory - the Presto Control will power up in the mode it was last powered down in Memory, Idle, Idle - The Presto Control powers up the detach Power Up Mode...

Need help?

Do you have a question about the Presto Master and is the answer not in the manual?

Questions and answers