Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Lika RD5

-

Page 1: User's Guide

User's guide RD53 RS-485 version Smart encoders & actuators... - Page 2 Tous droits réservés. This document and information contained herein are the property of Lika Electronic s.r.l. and shall not be reproduced in whole or in part without prior written approval of Lika Electronic s.r.l. Translation, reproduction and total or partial modification (photostat copies, film and microfilm included and any other means) are forbidden without written authorisation of Lika Electronic s.r.l.

-

Page 3: Table Of Contents

4.3.3 Setting data transmission rate: Baud rate and Parity bit (Figure 3)........22 4.3.4 RT bus termination (Figure 3)........................23 5 Quick reference........................... 24 5.1 Configuring the device using Lika setting up software................24 5.2 “Serial configuration” page..........................25 5.3 “Operative mode” page............................29 5.4 “Machine data” page............................33 5.5 “Message monitor”... - Page 4 8.1.1 Machine data parameters..........................62 Distance per revolution [00 hex].............................62 Position window [01 hex]..............................63 Position window time [02 hex]............................63 Max following error [03 hex]............................63 Kp position loop [04 hex]..............................64 Ki position loop [05 hex]..............................64 Acceleration [06 hex]................................64 Deceleration [07 hex]................................64 Positive delta [08-09 hex]..............................64 Negative delta [0A-0B hex]..............................65 Jog speed [0C hex].................................65 Work speed [0D hex]................................65...

- Page 5 Watch dog....................................75 Status word [01 hex]................................76 Axis in position..................................76 Axis enabled..................................76 SW limit switch +................................76 SW limit switch -................................76 Alarm.......................................76 Axis running..................................76 Executing a command..............................77 Target position reached..............................77 DAC saturation..................................77 Current position [02-03 hex]............................77 Current velocity [04 hex]..............................77 Position following error [05-06 hex]..........................77 Current value [07 hex].................................78 Temperature value [08 hex]...............................78 Wrong parameters list [09-0A hex]..........................78...

-

Page 6: Subject Index

Subject Index Ki current loop [11 hex]..........67 Absolute reading..............69 Ki position loop [05 hex]..........64 Acceleration [06 hex]............64 Kp current loop [10 hex]..........67 Alarm..................76 Kp position loop [04 hex]..........64 Alarm reset................70 Alarms register [00 hex]..........74 Load default parameters..........71 Axis enabled...............76 Axis in position..............76 Machine data not valid..........74 Axis not synchronized............74 Max current [12 hex]............67... -

Page 7: Typographic And Iconographic Conventions

In this guide, to make it easier to understand and read the text the following typographic and iconographic conventions are used: parameters and objects both of Lika device and interface are coloured in ORANGE; • alarms are coloured in RED;... -

Page 8: Preliminary Information

In the Modbus version the configuration of the ROTADRIVE unit can be done through a software expressly developed and released by Lika Electronic in order to allow an easy set up of the device. The program is supplied for free and can be installed in any PC fitted with a Windows operating system (Windows XP or later). -

Page 9: Safety Summary

• elsewhere in this manual violates safety standards of design, manufacture, and intended use of the equipment; Lika Electronic s.r.l. assumes no liability for the customer's failure to • comply with these requirements. 1.2 Electrical safety Turn OFF power supply before connecting the device;... -

Page 10: Mechanical Safety

The counter-electromotive force (back EMF) generated by the motor in case the shaft is forced to rotate due to a manual external force can cause irreparable damages to the internal circuitry. MAN RD5 RD53 MB E 1.1 Safety summary 10 of 92... -

Page 11: Identification

Information is listed in the delivery document too. Please always quote the order code and the serial number when reaching Lika Electronic s.r.l. for purchasing spare parts or needing assistance. For any information on the technical characteristics of the product refer to the technical catalogue. -

Page 12: Mounting Instructions

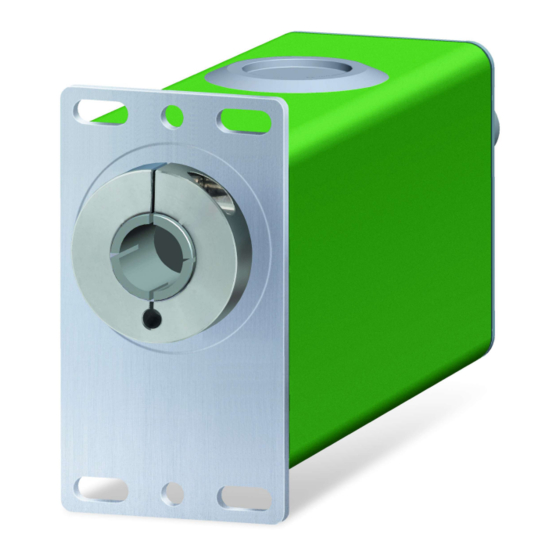

If this occurs, the mechanical tensions would be transmitted completely to the motor shaft and this would lead to bearings damages and mechanical breakdowns! MAN RD5 RD53 MB E 1.1 Mounting instructions 12 of 92... - Page 13 RD5 – RD53 Modbus® Figure 1 - Typical installation example of RD5-53 unit on worm screw To install properly the ROTADRIVE unit please read carefully and follow these instructions; anyway note that the unit can be installed in several manners and according to the specific user's application.

- Page 14 The counter-electromotive force (back EMF) generated by the motor in case the shaft is forced to rotate due to a manual external force can cause irreparable damages to the internal circuitry. MAN RD5 RD53 MB E 1.1 Mounting instructions 14 of 92...

-

Page 15: Electrical Connections

Lika's E- connectors have a plastic gland, thus grounding is not possible. If metal connectors are used, connect the cable shield properly as recommended by the manufacturer. -

Page 16: M12 Connectors (Figure 2)

(frontal side) male female (BUS IN) (BUS OUT) Description n.c. n.c. GND (RS-485) Modbus A (RS-485) Modbus B (RS-485) Case Shielding Lika's EC- pre-assembled cables only. n.c. = not connected MAN RD5 RD53 MB E 1.1 Electrical connections 16 of 92... - Page 17 Lika's E- connectors have a plastic gland, thus grounding is not possible (see Figure below). If metal connectors are used, connect the cable shield properly as recommended by the manufacturer.

-

Page 18: Dip-Switches And Diagnostic Leds (Figure 3)

To access the DIP-Switches and the diagnostic LEDs remove the plastic cover fitted on one side of the device. The DIP-switches and the diagnostic LEDs are located just beneath. Figure 3: Dip-Switches and diagnostic LEDs MAN RD5 RD53 MB E 1.1 Electrical connections 18 of 92... -

Page 19: Diagnostic Leds (Figure 3)

5 seconds both LEDs come on solidly red. For any information on restoring the unit please refer to the section “5.7 “Upgrade Firmware” page” on page 36. MAN RD5 RD53 MB E 1.1 Electrical connections 19 of 92... - Page 20 Indicates the motor is enabled (control loop activated) Indicates the motor is disabled (control loop deactivated) During initialisation, system checks the diagnostic LEDs for proper operation; therefore they blink for a while. MAN RD5 RD53 MB E 1.1 Electrical connections 20 of 92...

-

Page 21: Setting The Address Node: Node Id (Figure 3)

Each Slave must have a unique address. Addresses from 248 to 255 are reserved. If you set an address higher than 247, device will be set it to 247 automatically. MAN RD5 RD53 MB E 1.1 Electrical connections 21 of 92... -

Page 22: Setting Data Transmission Rate: Baud Rate And Parity Bit (Figure 3)

Set the baud rate to 9600 bits per second and Even parity bit: Switches Position Value Set the baud rate to 19200 bits per second and Odd parity bit: Switches Position Value MAN RD5 RD53 MB E 1.1 Electrical connections 22 of 92... -

Page 23: Rt Bus Termination (Figure 3)

Activated: when the device is at the end of 1 = 2 = ON the transmission line Deactivated: when the device is not at the end 1 = 2 = OFF of the transmission line MAN RD5 RD53 MB E 1.1 Electrical connections 23 of 92... -

Page 24: Quick Reference

RD5 / RD53 Modbus ROTADRIVE positioning units are supplied with a software expressly developed and released by Lika Electronic in order to allow an easy set up of the device. Program allows the operator to set the working parameters of the device;... -

Page 25: Serial Configuration" Page

First of all this page allows the operator to choose the language used to display texts and items in the user interface. Click the Italian flag icon to choose the Italian language; click the UK flag icon to choose the English language. MAN RD5 RD53 MB E 1.1 Quick reference 25 of 92... - Page 26 Before entering the next pages pressing the buttons in the menu on the left, it is necessary to establish a serial connection with the RD5x unit. To do so, open the Rotadrive type drop-down box and select the RD5-x model. MAN RD5 RD53 MB E 1.1...

- Page 27 (COM drop-down box) and then set the configuration parameters. Serial port settings in the personal computer must compulsorily match those in the connected Lika device. Default serial port settings as set at the factory by Lika Electronic for all RD5x- Modbus positioning units are the following: RD5x-Modbus...

- Page 28 CONNECT button disappears and is replaced by the DISCONNECT button. Furthermore the hardware version and the software version as well as the model of the device are shown in the Slave settings box. MAN RD5 RD53 MB E 1.1 Quick reference 28 of 92...

-

Page 29: Operative Mode" Page

In the top left-hand RD5x-MB box the following functions are available. Hold torque Axis torque item on page 72. This function is available only to RD5 version; in RD53 version this check-box is hidden. MAN RD5 RD53 MB E 1.1... - Page 30 For a normal halt of the device press the STOP button; for an immediate emergency halt press the EMERGENCY button. See Start item on page 71. MAN RD5 RD53 MB E 1.1 Quick reference 30 of 92...

- Page 31 INFINITE LOOP check box below allows the operator to activate the “infinite loop” function, i.e. the device goes on running and executing the set steps without interruption. MAN RD5 RD53 MB E 1.1 Quick reference 31 of 92...

- Page 32 (now labelled GO) to enable it again. The drop-down box below allows to choose the time scale in the horizontal axis of the graph. MAN RD5 RD53 MB E 1.1 Quick reference 32 of 92...

-

Page 33: Machine Data" Page

When you connect to a ROTADRIVE unit RD53 model, the BRAKE RELEASE check box appears just above the TUNING check box. Unlike RD5 model, RD53 model is fitted with a brake designed to activate as soon as the motor comes to a stop in order to prevent it from moving even slightly. - Page 34 71. When you need to load default parameters (they are set at the factory by Lika Electronic engineers to allow the operator to run the device for standard operation in a safe mode) press the LOAD DEFAULT PARAMETER button. For...

-

Page 35: Message Monitor" Page

When you press the OPEN button to confirm, the dialogue box closes and the full path of the selected file is shown in the display box of the Message MAN RD5 RD53 MB E 1.1 Quick reference 35 of 92... -

Page 36: Test Lika" Page

START SAVING button, its descriptive label is replaced by STOP SAVING label. Press the STOP SAVING button to stop saving the messages. 5.6 “Test Lika” page Test Lika page is reserved for use by Lika Electronic engineers and is not accessible to users. 5.7 “Upgrade Firmware” page By pressing the UPGRADE FIRMWARE button in the menu on the left side the operator enters the Upgrade Firmware page. - Page 37 The firmware upgrading program consists of a single file having .BIN extension. It is released by Lika Electronic Technical Assistance & After Sale Service. WARNING Firmware upgrading process in any ROTADRIVE unit has to be accomplished by skilled and competent personnel.

- Page 38 Please note that for each ROTADRIVE model having its own bus interface an appropriate firmware file is available. Make sure you have the appropriate update for your ROTADRIVE model. The .BIN file released by Lika Electronic has a file name that has to be interpreted as follows.

-

Page 39: If There Is An Installation Issue

5. Always make sure the correct serial port of the personal computer connected to the ROTADRIVE unit is selected in the Serial configuration page. MAN RD5 RD53 MB E 1.1 Quick reference 39 of 92... -

Page 40: Getting Started

(baud rate; see on page 22); the • default value set by Lika Electronic at factory set-up is “baud rate = 9600 bit/s, parity = Even”; if requested, set the node address (node ID; see on page 21); the default •... -

Page 41: Functions

The following scheme is intended to show schematically the working principle of system control logic. Trajectory Torque generator position limiter Current PI Temperature control generator control Power electronics Current transducer Motor + Reduction Absolute gear encoder MAN RD5 RD53 MB E 1.1 Functions 41 of 92... -

Page 42: Movements: Jog And Positioning

Work speed time position Target + tolerance target Target - tolerance time “Axis in position” delay start=1 “Axis in position”=1 MAN RD5 RD53 MB E 1.1 Functions 42 of 92... -

Page 43: Distance Per Revolution [00 Hex], Jog Speed [0C Hex], Work Speed [0D Hex], Preset [16-17 Hex], Positive Delta [08-09 Hex] And Negative Delta [0A-0B Hex]

1 [PPS] • Max. speed: maximum speed 1024 [PPS] • 1024: this is the maximum value you can set next to the Distance per revolution [00 hex] item (expressed in pulses). MAN RD5 RD53 MB E 1.1 Functions 43 of 92... - Page 44 SW limit switch + Max. = 0 + 130047 = + 130047 pulses (forward travel) SW limit switch - Max. = 0 - 130047 = - 130047 pulses (backward travel) MAN RD5 RD53 MB E 1.1 Functions 44 of 92...

- Page 45 = 0, the working stroke of the axis will SW limit span the maximum positive and negative limits range, that is max. switch + SW limit switch - + 63499 and max. – 63499. MAN RD5 RD53 MB E 1.1 Functions 45 of 92...

- Page 46 = -500, the working stroke of the axis will SW limit span the maximum positive and negative limits range, that is max. switch + SW limit switch - + 12199 and max. – 13199. MAN RD5 RD53 MB E 1.1 Functions 46 of 92...

-

Page 47: Modbus® Interface

RD5 – RD53 Modbus® Modbus® interface Lika ROTADRIVE positioning units are Slave devices and implement the Modbus application protocol (level 7 of OSI model) and the “Modbus over Serial Line” protocol (levels 1 & 2 of OSI model). For any further information or omitted specifications please refer to “Modbus Application Protocol Specification V1.1b”... -

Page 48: Modbus Frame Description

CRC (Cyclical Redundancy Checking): error checking field is the result • of a “Redundancy Checking” calculation that is performed on the message contents. This is intended to check whether transmission has MAN RD5 RD53 MB E 1.1 Modbus® interface 48 of 92... -

Page 49: Transmission Modes

The transmission mode and the serial port parameters must be the same for all devices on a Modbus Serial Line. All devices must implement the RTU mode, while the ASCII mode is an option. Lika devices only implement RTU transmission mode, as described in the following section. -

Page 50: Rtu Transmission Mode

The maximum size of the Modbus RTU frame is 256 bytes, its structure is as follows: Slave Function code Data Address 2 bytes 1 byte 1 byte 0 up to 252 byte(s) CRC Low CRC Hi MAN RD5 RD53 MB E 1.1 Modbus® interface 50 of 92... - Page 51 In this case the CRC will be calculated and checked only if the frame is actually addressed to the Slave. MAN RD5 RD53 MB E 1.1 Modbus® interface 51 of 92...

-

Page 52: Function Codes

Reserved function codes are not available for public use. 7.4.1 Implemented function codes Lika RD5x-Modbus positioning units only implement public function codes, they are described hereafter. 03 Read Holding Registers FC = 03 (03 hex) ro This function code is used to READ the contents of a contiguous block of holding registers in a remote device;... - Page 53 (register 7) Deceleration [07 contains the value 03 E8 hex, i.e. 1000 in decimal notation; hex] parameter (register 8) contains the value 05 DC hex, i.e. 1500 in decimal notation. MAN RD5 RD53 MB E 1.1 Modbus® interface 53 of 92...

-

Page 54: Read Input Register

(msb) and the second contains the low order bits (lsb). 04 Read Input Register For the complete list of input registers accessible using function code please refer to section “8.1.2 Input Register parameters” on page MAN RD5 RD53 MB E 1.1 Modbus® interface 54 of 92... - Page 55 Current position [02-03 hex] As you can see in the table, parameter (input registers 3 and 4) contains the value 00 00 2F F0 hex, i.e. 12272 in decimal notation. MAN RD5 RD53 MB E 1.1 Modbus® interface 55 of 92...

-

Page 56: Write Single Register

The normal response is an echo of the request, returned after the register contents have been written. 06 Write Single Register For the complete list of registers accessible using function code please refer to section “8.1.1 Machine data parameters” on page MAN RD5 RD53 MB E 1.1 Modbus® interface 56 of 92... - Page 57 Register value Lo As you can see in the table, the value 05 DC hex, i.e. 1500 in decimal notation, is Acceleration [06 hex] set in the parameter (register 7). MAN RD5 RD53 MB E 1.1 Modbus® interface 57 of 92...

-

Page 58: Write Multiple Registers

The normal response returns the function code, starting address and quantity of written registers. 16 Write Multiple Registers For the complete list of registers accessible using function code please refer to section “8.1.1 Machine data parameters” on page MAN RD5 RD53 MB E 1.1 Modbus® interface 58 of 92... - Page 59 Starting address Hi Starting address Hi Starting address Lo Starting address Lo Quantity of registers Hi Quantity of registers Hi Quantity of registers Lo Quantity of registers Lo Byte count MAN RD5 RD53 MB E 1.1 Modbus® interface 59 of 92...

- Page 60 Deceleration [07 hex] parameters (register 7) and (register 8) from the Slave having the node address 1 is as follows: Response PDU (in hexadecimal format) [01][10][00][06][00][02][A1][C9] where: [01] = Slave address MAN RD5 RD53 MB E 1.1 Modbus® interface 60 of 92...

- Page 61 Server within 1 second, the system Watch dog forces an alarm condition (the alarm message is invoked to appear as soon as the Modbus network communication is restored). MAN RD5 RD53 MB E 1.1 Modbus® interface 61 of 92...

-

Page 62: Programming Parameters

After having changed this parameter you must then set new values also in Jog speed [0C hex], Work speed [0D hex] Preset [16-17 parameters hex]. For a detailed explanation see on page 43 and relevant parameters. MAN RD5 RD53 MB E 1.1 Programming parameters 62 of 92... -

Page 63: Position Window [01 Hex]

Parameter is expressed in pulses. Default = 1024 (min. = 0, max. = 65535) MAN RD5 RD53 MB E 1.1 Programming parameters 63 of 92... -

Page 64: Kp Position Loop [04 Hex]

[Register 5, Unsigned16, rw] This parameter contains the proportional gain used by the PI controller for the position loop. Value has been optimized by Lika Electronic according to the technical characteristics of the device. Default = 500 (min. = 0, max. = 1000) -

Page 65: Negative Delta [0A-0B Hex]

Target position [2B-2C hex]). Parameter is order to reach the position set in expressed in pulses per second. Default = 1024 (min. = 1, max. = 1024) MAN RD5 RD53 MB E 1.1 Programming parameters 65 of 92... -

Page 66: Start Torque Current Time [0E Hex]

Therefore it is compulsory to set a new value in [16-17 hex] Positive parameter and then check the values set next to the delta [08-09 hex] Negative delta [0A-0B hex] items. MAN RD5 RD53 MB E 1.1 Programming parameters 66 of 92... -

Page 67: Kp Current Loop [10 Hex]

[Register 17, Unsigned16, rw] This parameter contains the proportional gain used by the PI controller for the current loop. Value has been optimized by Lika Electronic according to the technical characteristics of the device. Default = 300 (min. = 0, max. = 1000) -

Page 68: Preset [16-17 Hex]

Default = 100 (min. = 1, max. = 10000). MAN RD5 RD53 MB E 1.1 Programming parameters 68 of 92... -

Page 69: Extra Commands Register [29 Hex]

Byte structure of the byte … … Byte 0 Absolute reading bit 0: This function is reserved only for use and service of Lika Electronic engineers. bits 1 … 7 Not used. Byte 1 Not used. Control Word [2A hex]... -

Page 70: Jog

Jog step length [19 hex] item; then the slave stops and waits for another issue. bit 5 Not used. MAN RD5 RD53 MB E 1.1 Programming parameters 70 of 92... -

Page 71: Start

(“1”). Load default parameters bit 10 Default parameters (they are set at the factory by Lika Electronic engineers to allow the operator to run the device for standard operation in a safe mode) are restored at each rising edge of the bit; in other words, the default parameters loading operation is performed each time this bit is switched from logic level low (“0”) to logic level high... -

Page 72: Perform Counting Preset

14 This function is available only in RD53 version (model fitted with brake); in the RD5 version (model without brake) bit 14 is not used. RD53 model is fitted with a brake designed to activate as soon as the motor comes to a stop in order to prevent it from moving even slightly. - Page 73 (the alarm is invoked to appear as soon as the Modbus network communication is restored). NOTE Save parameters Save the set values using function. Should the power be turned off all data not saved will be lost! MAN RD5 RD53 MB E 1.1 Programming parameters 73 of 92...

-

Page 74: Input Register Parameters

Target position is over maximum travel limits. Emergency Emergency Control Word [2A hex] bit 6 Bit 7 has been forced to low value (0); or alarms are active in the unit. MAN RD5 RD53 MB E 1.1 Programming parameters 74 of 92... -

Page 75: Overcurrent

Please note that should the alarm be caused by wrong parameter values (see Machine data not valid Wrong parameters list [09-0A hex]), normal Flash memory work status can be restored only after having set proper values. error alarm cannot be reset. MAN RD5 RD53 MB E 1.1 Programming parameters 75 of 92... -

Page 76: Status Word [01 Hex]

If value is “=1” an alarm has occurred, see details in Alarms register [00 hex] variable. Axis running bit 6 If value is ”=0” device is not moving. If value is “=1” device is moving. MAN RD5 RD53 MB E 1.1 Programming parameters 76 of 92... -

Page 77: Executing A Command

If this value is greater than the one set in the following error [03 hex] Following error parameter, then the alarm is triggered and the unit stops. Value is expressed in pulses. MAN RD5 RD53 MB E 1.1 Programming parameters 77 of 92... -

Page 78: Current Value [07 Hex]

Deceleration [07 hex] Positive delta [08-09 hex] Negative delta [0A-0B hex] Jog speed [0C hex] Work speed [0D hex] Start torque current time [0E hex] Code sequence [0F hex] MAN RD5 RD53 MB E 1.1 Programming parameters 78 of 92... -

Page 79: I2T [0B Hex]

The meaning of the 16 bits in the register is as follows: 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00 Ms bit Ls bit Major number Minor number MAN RD5 RD53 MB E 1.1 Programming parameters 79 of 92... -

Page 80: Hw Version [0F Hex]

08 .. 11 = interface (00 = Modbus; 01 = Profibus; 02 = CANopen; 03 … 0F = bits not used) 12 … 15 = ROTADRIVE model (00 = RD4; 01 = RD1xA; 02 = RD5; 03 … 0F = bits not used) - Page 81 Status word (bit 7 - hex]) Axis running (bit 6 - Status word [01 hex]) Axis enabled Status word [01 (bit 2 - hex]: PWM is active) Theoretical velocity MAN RD5 RD53 MB E 1.1 Programming parameters 81 of 92...

-

Page 82: Exception Codes

For any information on the available exception codes and their meaning refer to the section “MODBUS Exception Responses” on page 48 of the “MODBUS Application Protocol Specification V1.1b” document. MAN RD5 RD53 MB E 1.1 Programming parameters 82 of 92... -

Page 83: Programming Examples

(register 7) contains the value 03 E8 hex, i.e. Deceleration [07 hex] 1000 in decimal notation; parameter (register 8) contains the value 05 DC hex, i.e. 1500 in decimal notation. MAN RD5 RD53 MB E 1.1 Programming examples 83 of 92... -

Page 84: Using The 04 Read Input Register Function Code

1. Request PDU [01][04][00][00][00][01][31][CA] where: [01] = Slave address 04 Read Input Register [04] = function code (Alarms register [00 hex] [00][00] = starting address variable, register 1) MAN RD5 RD53 MB E 1.1 Programming examples 84 of 92... - Page 85 This means that in the variable (register 1) bits 0 and Machine data not valid 7 are active (logic level high = 1), i.e. (see on page 74): and Emergency. MAN RD5 RD53 MB E 1.1 Programming examples 85 of 92...

-

Page 86: Using The 06 Write Single Register Function Code

[06] = function code (Control Word [2A hex] [00][2A] = address of the register variable, register 43) [00][84] = value to be set in the register [A8][61] = CRC MAN RD5 RD53 MB E 1.1 Programming examples 86 of 92... - Page 87 (bit 2 Stop = 0) but not in emergency condition (bit 7 Emergency Save parameters = 1); furthermore data save is requested (bit 9 = 1). MAN RD5 RD53 MB E 1.1 Programming examples 87 of 92...

-

Page 88: Using The 16 Write Multiple Registers Function Code

The value 05 DC hex, i.e. 1500 in decimal notation, is set in the [06 hex] parameter (register 7); the value 03 E8 hex, i.e. 1000 in decimal Deceleration [07 hex] notation, is set in the parameter (register 8). MAN RD5 RD53 MB E 1.1 Programming examples 88 of 92... -

Page 89: Default Parameters List

Ki current loop [11 hex] Max current [12 hex] mA 2000 Starting torque current 4000 [13 hex] mA Preset [16-17 hex] P Jog step length [19 hex] P MAN RD5 RD53 MB E 1.1 Default parameters list 89 of 92... - Page 90 This page intentionally left blank...

- Page 91 This page intentionally left blank...

- Page 92 [01 hex], Max following error [03 hex], Jog step length [19 hex] updated Dispose separately LIKA Electronic Via S. Lorenzo, 25 36010 Carré (VI) • Italy Tel. +39 0445 806600 Fax +39 0445 806699 Italy: eMail info@lika.it - www.lika.it World: eMail info@lika.biz - www.lika.biz...

Need help?

Do you have a question about the RD5 and is the answer not in the manual?

Questions and answers