Advertisement

Quick Links

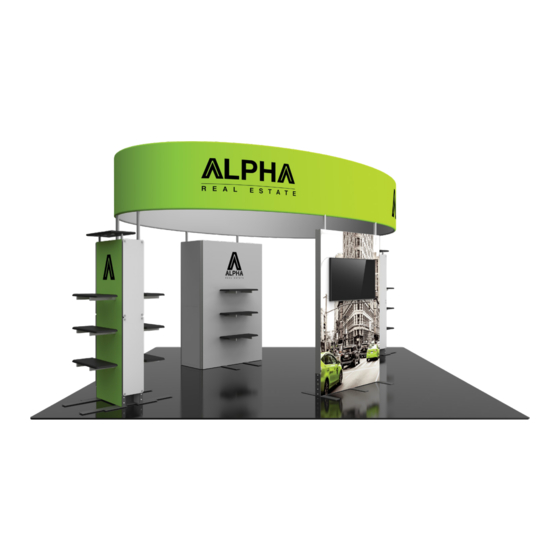

HYBRID PRO 20X20 MODULAR ISLAND KIT 32

HP-K-32

Hybrid Pro™ Modular Kit 32 offers a combination of both multimedia and plenty of

shelving for small products to be on display. Two displays anchor the exhibit on the

sides - each includes six shelves, push-fit fabric graphics behind the shelves, frosted

plexiglass on the sides and a canopy that includes puck lights to illuminate the prod-

ucts on display. The two other anchored displays also offer functionality and features!

Larger in footprint, one of the ground-based displays features a storage closet with

easy access and a locking door; one side has a large/medium monitor mount and the

other has three shelves for more product display.

We are continually improving and modifying our product range and reserve the right to vary the specifications without prior notice.

All dimensions and weights quoted are approximate and we accept no responsibility for variance. E&OE. See Graphic Templates

for graphic bleed specifications.

07/01/2019

features and benefits:

- 11'5" tall island display

- No rigging required

- 19'w x 3'h oval fabric structure

- Two identical displays include six shelves,

canopy with puck lights, frosted plex sides

and push-fit fabric graphics

dimensions:

Hardware

Assembled unit:

279.19"w x 149.96"h x 54"d

7092mm(w) x 3309mm(h) x 1372mm(d)

Approximate Hardware weight:

2346 lbs / 1065 kg

Approximate Graphic weight:

63 lbs / 29 kg

Shipping

Packing case(s):

1 FS-CREATE

1 WOODCREATE-H

Shipping dimensions:

FS-CREATE:

52"l x 29"h x 15"d

1321mm(l) x 737mm(h) x 381mm(d)

WOODCREATE-H:

52"l x 29"h x 15"d

1321mm(l) x 737mm(h) x 381mm(d)

Approximate total shipping weight:

2875 lbs / 1305 kg

This product may include the following

materials for recycle:

aluminum, select wood, fabric, cardboard,

paper, steel, and plastics.

- Locking strorage closet has monitor mount

on one side and three shelves on the other

- Wall display includes monitor mount for

multimedia display / presentaiton and

includes push-fit fabric graphics

- Ships freight

Graphic

Refer to related graphic template for more

information.

Visit:

https://www.theexhibitorshandbook.com/

download-graphic-templates

additional information:

Graphic material:

Dye-sublimation zipper pillowcase fabric

Dye-sublimation SEG push-fit fabric

When included in a larger kit, a different

packaging solution will be listed to

accommodate all contents of the kit.

Individual packaging no longer provided

Monitor mount holds 32"- 55" LCD

Monitor mount holds max weight: 50 lbs / 19 kg

Tabletop Colors:

natural

black

mahogany

silver

2 person assembly recommended:

Advertisement

Summary of Contents for Exhibitor's Handbook HYBRID PRO HP-K-32

- Page 1 HYBRID PRO 20X20 MODULAR ISLAND KIT 32 features and benefits: HP-K-32 Hybrid Pro™ Modular Kit 32 offers a combination of both multimedia and plenty of - 11’5” tall island display - Locking strorage closet has monitor mount shelving for small products to be on display. Two displays anchor the exhibit on the - No rigging required on one side and three shelves on the other sides - each includes six shelves, push-fit fabric graphics behind the shelves, frosted...

-

Page 2: Included In Your Kit

Included In Your Kit 5MM ALLEN-T x1 CB9 x28 IB2 x14 PHFC4-1200-L1-MCB9-SIDE x8 PHFC4-725-L-MCB9 x10 PM2S2-1200-A165-N x6 PH4-300-TG x3 PH2-578-L-L x2 PHFC4-1200-L1-MCB9 x4 PHFC4-725-L-MCB9-GR x2 PHFC2-1000-L1-MCB9 x8 PHFC2-1200-L1-MCB9 x8 PHFC2-750-MCB9-MCB9 x8 PS2-660-L-L x2... - Page 3 Included In Your Kit HP-K-32-T1 x2 HP-K-32-T2 x4 HP-K-32-T10 x12 HP-K-32-T5 x4 HP-K-32-T8 x2 HP-K-32-T9 x4 HP-K-32-T4 x4 HP-K-32-T3 x4 HP-K-32-T6 x2 HP-K-32-T7 x2 ES50 x14...

- Page 4 Included In Your Kit FC-50-SPCR x12 HP-SOFFET-1 x2 PM4S3-MK-SHELF-UNIT x5 EXT-M-MB x2 SW-FOOT-650-LN x2 SW-FOOT-LN x8 CBE-50 x24 LN114-S2-650 x1 P90S-1200 x8 LP-CD-600-1200 x2 LP-600-1200 x2...

- Page 5 Included In Your Kit HP-32-E2-G x1 HP-32-E3-G x1 HP-32-F2-G x1 HP-32-E5-G x1 HP-32-E6-G x1 HP-32-F3-G x1 HP-32-F5-G x1 HP-32-F6-G x1 CKSO x32...

- Page 6 Included In Your Kit HP-32-E4-G x1 HP-32-E1-G x1 HP-32-A-G x1 HP-32-B-G x1 HP-K-32-G-G x1 HP-32-C-G x1 HP-32-D-G x1 HP-32-F1-G x1 HP-32-F4-G x1 HP-32-H1-G x1 HP-32-H2-G x1 HP-32-I1-G x1 HP-32-I2-G x1...

- Page 7 Suggested Kit Layout HP-K-32 Section 1.4 Section 1.5 Section 1.2 Section 1.3 Section 1.1...

-

Page 8: Exploded Diagram

Exploded Diagram HP-K-32 Section 1.1 Reference the Suggested Layout page for build location. - Page 9 Exploded Diagram HP-K-32 Section 1.1 Reference the Suggested Layout page for build location.

- Page 10 Exploded Diagram HP-K-32 Section 1.1 Reference the Suggested Layout page for build location. HP-32-B-G HP-32-A-G...

- Page 11 Exploded Diagram HP-K-32 Section 1.2 & Section 1.3 Reference the Suggested Layout page for build location.

- Page 12 Exploded Diagram HP-K-32 Section 1.2 & Section 1.3 Reference the Suggested Layout page for build location.

- Page 13 Exploded Diagram HP-K-32 Section 1.2 & Section 1.3 Reference the Suggested Layout page for build location. HP-32-H1-G HP-32-I1-G HP-32-E4-G HP-32-E1-G HP-32-E4-G HP-32-F1-G Section 1.2: E-G & H-G Section1.3: F-G & I-G HP-32-H2-G HP-32-I2-G...

- Page 14 Exploded Diagram HP-K-32 PM4S3-MK-SHELK Section 1.1, 1.2, 1.3 & 1.4 Reference the Suggested Layout page for build location. **THE PM4S3-MK-SHELF-UNIT MUST BE BUILT AND PUT IN PLACE BEFORE ATTACHING THE 2 FRAMES TOGETHER. ** TO START THE NEXT STEP REMOVE THE SHELF TOPS TO ATTACH GRAPHICS.

- Page 15 Exploded Diagram HP-K-32 Section 1.2 & Section 1.3 Reference the Suggested Layout page for build location.

- Page 16 Exploded Diagram HP-K-32 Section 1.2 & Section 1.3 Reference the Suggested Layout page for build location.

- Page 17 Exploded Diagram HP-K-32 Section 1.2 & Section 1.3 Reference the Suggested Layout page for build location. HP-32-E3-G HP-32-F3-G HP-32-E5-G HP-32-F5-G Section 1.2: E-G Section1.3: F-G HP-32-E2-G HP-32-F2-G HP-32-E6-G HP-32-F6-G...

- Page 18 Exploded Diagram HP-K-32 Section 1.4 Reference the Suggested Layout page for build location.

- Page 19 Exploded Diagram HP-K-32 Section 1.4 Reference the Suggested Layout page for build location.

- Page 20 Exploded Diagram HP-K-32 Section 1.5 Reference the Suggested Layout page for build location.

- Page 21 Exploded Diagram HP-K-32 Section 1.5 Reference the Suggested Layout page for build location.

- Page 22 Exploded Diagram HP-K-32 Section 1.5 Reference the Suggested Layout page for build location. HP-32-G-G...

-

Page 23: Kit Assembly

Kit Assembly Step by Step Step 17. Step 18. Gather the components to build Gather the components to build the frame. Use the Exploded the frame. Use the Exploded View and the Labeling Diagram View and the Labeling Diagram for part labels. for part labels. - Page 24 Kit Assembly Step by Step Step 21. Step 22. PH2-350-L-L Collect your extrusions and Locate the M5 thumbscrews, handtool. Using the provided LN100s, and the PM4S3- handtool, lock the extrusions into MM stabilizing bases. Slide the back channel of the three the LN100s into the middle channel PM4S3 faces as shown channel of the PM4S3.

- Page 25 Shelf Measurements...

- Page 26 Kit Assembly Step by Step Step 25. Step 26. Attach side graphics will CKSO. Gather the components to build The CKSO will connect in the the frame. Use the Exploded View center channels of the outside of and the Labeling Diagram for part the frame.

- Page 27 Kit Assembly Step by Step Step 29. Step 30. Attach side graphics will CKSO. Gather the components to attach The CKSO will connect in the mount. Use the Exploded View center channels of the outside of and the Labeling Diagram for part the frame.

- Page 28 Kit Assembly Step by Step Step 33. Step 34. Gather the components to build Gather the components to build the frame. Use the Exploded View the frame. Use the Exploded View and the Labeling Diagram for part and the Labeling Diagram for part labels.

- Page 29 Kit Assembly Step by Step Step 37. Attach soffets to proper area’s. Use the Exploded View and the Labeling Diagram for part labels. Reference Connection Method(s) 19 for more details.

-

Page 30: Connection Methods

Connection Methods Connection Method 1: CB9 Connection Method 2: IB2 First, insert the corner connector into the extrusion while holding in the lock button. Then, slide First, insert the in-line connector into the extrusion while holding in the lock button. Then, slide the next extrusion onto the same corner connector again holding in the lock button. - Page 31 Connection Methods Connection Method 5: CBE-50 Connection Method 2: IB2 Connection Method 6: SW-FOOT-300/500/650 First, use the provides hex tool to loosen the two 5mm hex set screws. Next, compress the bracket First, loosen the thumb screws and channel bars on the stabilizing bases. Do not disassemble them. and apply it to the corner channel.

- Page 32 Connection Methods Connection Method 9: Graphic Application Connection Method 5: CBE-50 Connection Method 2: IB2 Connection Method 10: CKSO First, insert the silicone edge frame corners into the frame graphic channel (points 1 through 4). Screw the NT toggle into the base of the CKSO barrel and then insert the TN into the channel of the Second, insert the silicone edge frame sides into the frame graphic channel (points 5 through 8).

- Page 33 Connection Methods Connection Method 13: PS2 to PM2S2 Connection Method 5: CBE-50 Connection Method 2: IB2 Connection Method 14: CKSO First, connect PS2 to PM2S2 side with 1 channel. Once parts are connected to the proper channel, First attach the P90S to panels. Then lock them once in place with cam locks. Next step, is to attach use tool to tighten lock to scure the PS2 in place.

- Page 34 Connection Methods Connection Method 17: ES50 TO PHFC4 Connection Method 2: IB2 Connection Method 18: ES50 TO PHFC2 Attach ES50 to PHFC4 extrusion. Make sure cam lock is loosed enough to fit inside desired channel. Attach ES50 to PHFC2 extrusion. Make sure cam lock is loosed enough to fit inside desired channel. Once in place tighten.

- Page 35 Monitor Bracket Instructions Extrusion Channel Applications EXT-SM-MB EXT-M-MB EXT-LG-MB Vesa Pattern: 75 x 75 Vesa Pattern: 200 x 200 Vesa Pattern: 200 x 200 up to 200 x 200mm up to 400 x 400mm up to 600 x 400mm Max weight varies per application Max weight varies per application Max weight varies per application Assembled unit:...

- Page 36 Extrusion Connection Channel Connection A Locate all components needed to assemble the monitor mount with the channel connection A method. You will need (1) monitor bracket, (2) square head bolts, (2) washers, and (2) wing nuts. Step 1: Insert the provided bolts through the washers and center top and bottom holes of the monitor mount.

- Page 37 Extrusion Connection TRI-30MM Channel Tube Connection Locate all components needed to assemble the monitor mount with the TRI-30MM Channel Tube Connection method. You will need (1) monitor bracket, (2) Square Bolts, and (2) Wingnuts. Step 1: Slip the head of the square bolts into the extrusion channel of the tube.

- Page 38 Freestanding Monitor Kiosk features and benefits: PM4S3-MK-M PM4S3-MK-M-MSHELF PM4S3-MK-SHELF-UNIT PM4S3-MK-L PM4S3-MK-L-MSHELF - Premium aluminum extrusion frames with - Kits may include: a medium or large The Freestanding Monitor Kiosk is a superior multimedia display that can be used for cam lock and tension glide assembly monitor mount, shelf, or combination multiple applications, as well as in trade show exhibits and for events.

- Page 39 Included In Your Freestanding Monitor Kiosk PM4S3-MM-FOOT-R x1 LN100 x6 M5 THUMBSCREW x8 5MM ALLEN-T x1 PM4S3-MM-FOOT-L x1 PH2-350-L-L x3 PH5-100-L-L x2 PM4S4-150 x2 PM4S3-600-A165-A165 x2 PM4S3-1200-A165-A165 x2 PH2-300-TG x2 EXT-M-MB (or) EXT-LG-MB x1 CBE-50 x2 Fastening Hardware Included...

- Page 40 Included In Your Freestanding Monitor Kiosk with Shelf PM4S3-MM-FOOT-R x1 LN100 x6 M5 THUMBSCREW x8 5MM ALLEN-T x1 PM4S3-MM-FOOT-L x1 PH2-350-L-L x3 PH5-100-L-L x2 PM4S4-150 x2 PM4S3-600-A165-A165 x2 PM4S3-1200-A165-A165 x2 PH2-300-TG x2 EXT-M-MB (or) EXT-LG-MB x1 CBE-50 x4 Fastening Hardware Included...

- Page 41 Included In Your Freestanding Monitor Kiosk with Shelf PH-400-L-SIDE-MK x2 PE-1200 x2 CT21-MK-SHELF x1 LN605-EN x2 *will ship preattached to shelf...

- Page 42 Included In Your Freestanding Shelf PM4S3-MM-FOOT-R x1 LN100 x6 M5 THUMBSCREW x8 5MM ALLEN-T x1 PM4S3-MM-FOOT-L x1 PH2-300-TG x2 PH2-350-L-L x3 PM4S3-600-A165-A165 x2 PM4S3-1200-A165-A165 x2 PH-400-L-SIDE-MK x6 PE-1200 x6 CT21-MK-SHELF x3 LN605-EN x6 *will ship preattached to shelf...

-

Page 43: Exploded View

Exploded View PM4S3-MK-M PM4S3-MK-L Please note: This is the kiosk frame build for either medium or large kit. - Page 44 Exploded View PM4S3-MK-M-MSHELF PM4S3-MK-L-MSHELF...

- Page 45 Exploded View PM4S3-MK-SHELF-UNIT PH2-350-L-L PM4S3-600-A165-A165 PM4S3-600-A165-A165 CT21-MK-SHELF PH-400-L-SIDE-MK PH-400-L-SIDE-MK LN605-EN LN605-EN PH2-350-L-L PH2-300-TG PH2-300-TG PM4S3-1200-A165-A165 CT21-MK-SHELF PH-400-L-SIDE-MK PH-400-L-SIDE-MK PM4S3-1200-A165-A165 LN605-EN LN605-EN CT21-MK-SHELF PH2-350-L-L PH-400-L-SIDE-MK PH-400-L-SIDE-MK LN605-EN LN-100 LN-100 LN-100 LN-100 PH2-350-L-L PM4S3-MM-FOOT-L LN605-EN PM4S3-MM-FOOT-R...

-

Page 46: Kit Assembly

Kit Assembly Step by Step Step 1. Step 2. PH2-350-L-L PM4S3-600-A165-A165 Reference the image to the right. Collect your extrusions and Locate the coded extrusions. Slide handtool. Using the provided the PH2-300-TG connector into handtool, lock the extrusions into one end of the PM4S3-1200- the back channel of the three A165-A165 so that it goes as channel PM4S3 faces as shown in... - Page 47 Kit Assembly Step by Step - Monitor Mount Step 4. Step 5. This step is for kiosks with NOTE: Your main backwall Square monitor mounts. Skip to step 7 assembly must be completed with Head for shelf kiosks. graphics before completing this Bolt step of the monitor kit.

- Page 48 Kit Assembly Step by Step - Shelf Step 7. Step 8. Insert the LN605-EN end caps. Lock your PH-400-L-SIDE-MK into Lock the CT21-MK-SHELF to the the PM4S3 stacks at the desired PH-400-L-SIDE-MK. Do not over dimension height. Do not over tighten.

- Page 49 Freestanding Display Shelf features and benefits: PM4S3-MK-SHELF Freestanding display shelves are easily attached to your assembled kiosk for - Premium aluminum extrusion frames with - Lifetime limited hardware warranty against displaying promotional materials. This shelf can be added to a Freestanding Monitor cam lock and tension glide assembly manufacturer defects Kiosk order.

- Page 50 Included In Your Freestanding Display Shelf PH-400-L-SIDE-MK x2 PE-1200 x2 CT21-MK-SHELF x1 LN605-EN x2 *will ship preattached to shelf...

- Page 51 Exploded View PM4S3-MK-SHELF CT21-MK-SHELF PE-1200 PE-1200 PH-400-L-SIDE-MK PH-400-L-SIDE-MK LN605-EN LN605-EN *Note: PE will ship preattached to shelf...

- Page 52 Kit Assembly Step by Step - Shelf Step 8. Step 7. Insert the LN605-EN end caps. Lock your PH-400-L-SIDE-MK into Lock the CT21-MK-SHELF to the the PM4S3 stacks at the desired PH-400-L-SIDE-MK. Do not over dimension height. Do not over tighten.

- Page 53 Note: tape comes preattached to extrusion, 0” starts from the bottom (at the floor)

Need help?

Do you have a question about the HYBRID PRO HP-K-32 and is the answer not in the manual?

Questions and answers