Summary of Contents for Hanatek FILM SHRINK TESTER

- Page 1 OPERATING MANUAL FILM SHRINK TESTER ©Rhopoint Instruments Ltd. Rhopoint House • Enviro 21 Park • Queensway Avenue South St Leonards on Sea • TN38 9AG UK Web: www.hanatekinstruments.com • Main Office: +44 (0)1424 739 623...

-

Page 2: Table Of Contents

RoHS and WEEE ....................................10 Product Safety WARNING REASONABLE CARE MUST BE TAKEN AT ALL TIMES – THE HANATEK FILM SHINK TESTER HAS HOT AREAS ON THE TOP OF THE INSTRUMENT THAT CONSTITUTE BURNING HAZARADS. CARE SHOULD BE TAKEN AT ALL TIMES. SUITABLE PROTECTIVE EYEWEAR/CLOTHING/HEATPROOF GLOVES SHOULD BE WORN WHERE NECESSARY. -

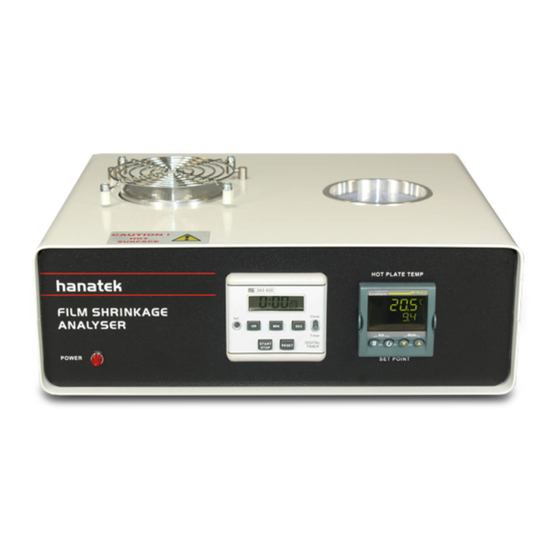

Page 3: Equipment

Equipment Package Contents Hanatek Film Shrink Tester Mains lead – US (for 115V) Sample Template - 50mm diameter Calibration certificate for instrument Pack of Foil Disks – 70mm diameter (25) Knife Silicon Oil Manual Mini pipette Tweezer Mains leads – EU&UK (for 240V) -

Page 4: Operation

Operation Assembly • Remove the instrument from all packaging. Retain the packaging so that the equipment can be returned for calibration and service repairs. • Place the instrument on a suitable bench ensuring the instrument is level. • Check the hot-plate grill is in the ‘down’ position. Powering the instrument •... -

Page 5: Sample Preparation

Sample Preparation Sample selection • Identify the area of the sample to be tested. It should be free from contamination and creases. Using the sample templates • Position the supplied template over the area and carefully cut around the template. •... -

Page 6: Performing A Test

Performing a Test Running a test • Add a few drops of silicon oil to the hot-plate (figure 3). This will form a film approximately 0.25mm thick. Figure 3 • Place a foil disk, with the edges turned up, in the heating area. •... -

Page 7: Test Results

Test Results Evaluation of test results Generally, because of different properties with and across the machine direction, shrinkage is anisotropic, and the discs will have assumed an elliptical shape. Noting the machine direction, measure both the ‘Major’ and ‘Minor’ axes. The result is then reported as a percentage of the original dimension. -

Page 8: Service And Repair

Service and Repair Calibration To maintain the optimum performance of this machine Hanatek Instruments recommends an annual recalibration of the equipment. A full list of service centres can be found on the Hanatek website: https://www.hanatekinstruments.com/support/authorised-service-centres/ Spares Product Order Code Silicone oil, 50ml... -

Page 9: Certificate Of Conformity

Certificate of Conformity... -

Page 10: Rohs And Weee

RoHS and WEEE EU Directive 2002/96/EC on WEEE (Waste Electrical & Electronic Equipment) and RoHS (Restriction of the use of certain Hazardous Substances). The European Union's Directive on Restriction of the use of certain Hazardous Substances in electrical and electronic equipment (ROHS) defines each of 10 categories of electrical and electronic equipment in Annex I .

Need help?

Do you have a question about the FILM SHRINK TESTER and is the answer not in the manual?

Questions and answers