Table of Contents

Advertisement

Quick Links

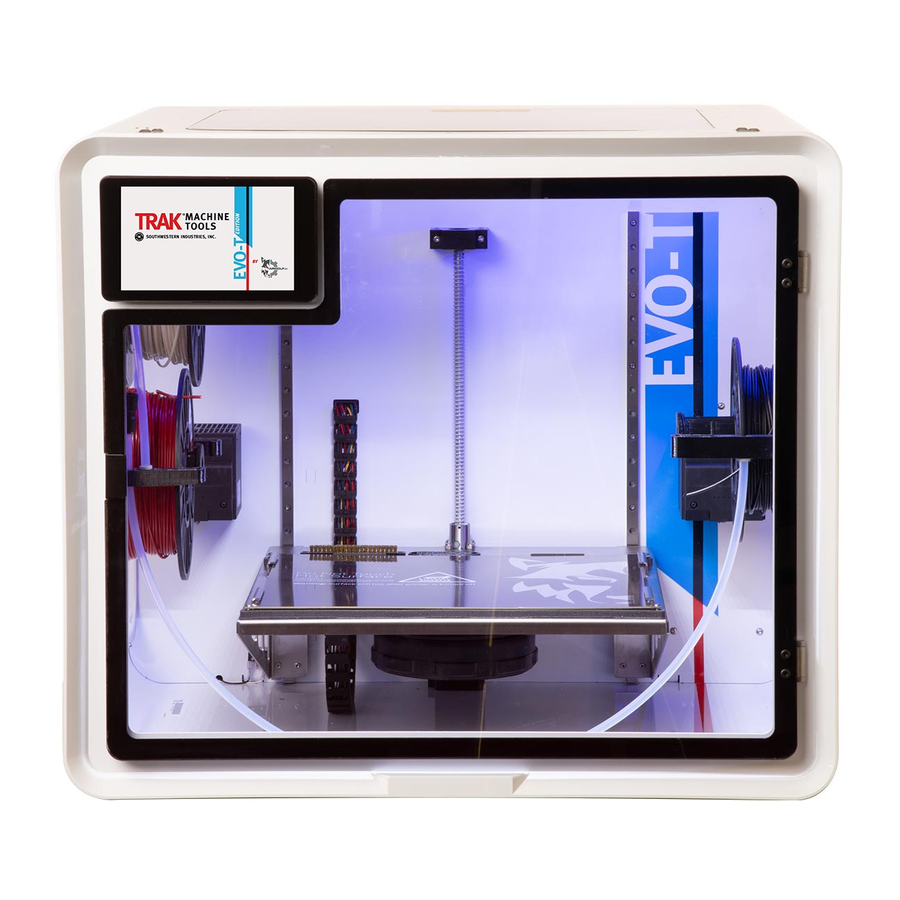

Airwolf EVO 3D Printers

Installation, Printing, Maintenance & Troubleshooting Manual

Covers Current Models:

• EVO-T

• EVO22-T

2615 Homestead Place

Rancho Dominguez, CA 90220-5610 USA

T | 310.608.4422 | F | 310.764.2668

Service Department: 800.367.3165

e-mail:

sales@trakmt.com

|

TRAK Edition

service@trakmt.com

Document: P/N 32502

Version:

031221

|

web:

www.trakmt.com

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for TRAK Airwolf EVO-T

- Page 1 Airwolf EVO 3D Printers TRAK Edition Installation, Printing, Maintenance & Troubleshooting Manual Document: P/N 32502 Covers Current Models: Version: 031221 • EVO-T • EVO22-T 2615 Homestead Place Rancho Dominguez, CA 90220-5610 USA T | 310.608.4422 | F | 310.764.2668 Service Department: 800.367.3165 e-mail: sales@trakmt.com...

- Page 2 Industries, Inc. assumes no responsibility for inaccuracies or omission and accepts no liability for damages resulting from the use of the information contained in this guide. All brand names and products are trademarks or registered trademarks of their respective holders. TRAK Machine Tools Southwestern Industries, Inc. 2615 Homestead Place Rancho Dominguez, CA 90220-5610 Phone 310.608.4422 ▪...

-

Page 3: Table Of Contents

Verify material type, quantity, and nozzle configuration ..........28 4.1.4. WolfBite ........................30 (if needed) 4.1.5. Material & Nozzle Change Procedures ............32 Printing ..........................38 Post-Printing ........................38 TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... - Page 4 Print Too Close or Too Far from Bed ..................49 Layer Shifting ........................50 Filament Jam ........................50 6.5.1. Additional Filament Jam Procedure ................51 TRAK Warranty Policy ........................54 TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

-

Page 5: Printer Model & Serial Number

The plate below is for you to write down your model and serial number. Keep this info handy for when you contact Customer Service. Serial Number: ____________________________ Buytrakparts.com Login Credentials Login: ____________________________ Password: ____________________________ TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 6: Safety

Burn Hazard Hot Surface Hazard Fire Hazard Risk of Crush Crush Hazard Pinch Hazard Electromagnetic Interference Toxic Fumes Hazard Electrocution Hazard Hazard TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 7: Safety Precautions

Flammable materials or liquids should never be placed, stored next to, or in the printer. • The internal electronic components can cause electric shock even when the printer is powered down or unplugged. Never remove the back panel without consulting TRAK first. • ALWAYS disconnect ALL power to the printer before performing any repairs. -

Page 8: Site Prep & Requirements

8GB onboard memory Hard Disk Space 500 MB free disk space Core i3 or higher/AMD Core Processor Core i5 or higher Athelon 64bit or higher TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 9: Floor Plan, Layout & Space Requirements

2.2 Floor Plan, Layout & Space Requirements This section has dimension information for the EVO-T and EVO22-T. 2.2.1. EVO-T Front View Side View TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 10: Evo22-T

2.2.2. EVO22-T Front View TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 11: Installation Process

Uncrating & Unpacking 1. Cut off the straps that are holding the main box (which contains the actual Airwolf EVO-T 3D Printer) and the secondary box (which contains the 3D printer’s accessories) to the pallet. - Page 12 14. Remove the clip attached to the Z Stage Ball screw by pulling on the zip tie that is attached to the clip. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

-

Page 13: Packing List

1 – Quick Change Modular Hot-end Assembly • 1 – USB Male-to-Male Cord • 1 – Build Plate – Flex-Resistant Borosilicate • 1 – TRAK USB Drive Glass, 4mm • 1 – Benchmark Part, Euclid Block • 1 – HEPA & Carbon Filter Set Materials •... -

Page 14: Benchmark Part: Euclid Block

• Use MG94 ABS, natural color, and make sure it is DRY. • Use the exact same G-Code we saved on your internal drive. If you need another copy, call TRAK Customer Service. • Make sure you watch the first layer print before walking away from your printer. -

Page 15: Orientation, Controls & Functions

EVO-T EVO22-T TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... - Page 16 3.4.1.1. Internal Components TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

- Page 17 It heats up to 160°C. 6. Print Bed – The print bed is the horizontal surface that holds and heats the glass build plate. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

- Page 18 Filament Spool - Filament Spools can come with various materials, and in two sizes: 2.2lbs and 5 lbs. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

- Page 19 USB, and saving the file directly to the internal drive. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

-

Page 20: Installation Of Additional Components

NOTE – You may push down on the build plate slightly, to get it to slide smoothly. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 21: Connecting The Cables, Powering On

4. Flip the power switch on (on the side of the printer) 5. You should see your LCD screen start to power on. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 22: Lcd Overview

7. Nozzle 2 Current Temp – (34°C) – Ranges from 0°C to 315°C Nozzle 2 Target Temp – (0°C) – Ranges from 0°C to 315°C TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 23: Print Menu

4. File Manager – When you select the “File Manager” icon, the “Save/Delete” icon will appear (on the right), and allow you to Save/Delete files. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 24: Preheat Menu

1. Most Commonly Printed Materials - Displays the most commonly printed materials for you to select from. 2. More Material Options – Takes you to a list of many additional materials you can select from. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 25: Control Menu

5. Z Axis Slider – Use the slider to control how much you want to move the print bed up or down. Note – When a print job has completed, the print bed automatically resets to the bottom of the chamber. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 26: Settings Menu

3. Update Touchscreen – You can update the touchscreen software via ethernet or Wi-Fi. 4. Next – Takes you to the next page to see more settings. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... - Page 27 Ethernet MAC address, WIFI MAC address, Firmware version, APP Version, Filament Usage, and Heater Usage. 4. Back | Next – Allows you to switch between the previous screen and the next screen TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

- Page 28 3. Advanced – Additional/Advance features will show up here, allowing you to enable/disable them. Please consult TRAK before using them, if you do not understand what they are, or do. 4. Back – Takes you to the previous page in the settings menu.

-

Page 29: Connectivity

In this example, it displays 0.0.0.0, but on your printer, you should have an actual IP Address. Ex: 192.168.0.1 Your printer is now connected to the internet! TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 30: Printing

6. Print your Part from USB Drive or Internal Drive Post-Printing 7. Let the print cool down & remove Post-Processing 8. Support Removal 9. Additional Post Processing TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 31: Pre-Printing Steps

4.1.1. Verify all printer maintenance & firmware is up to date Printer maintenance is a critical step in the printing process that is too often overlooked. At TRAK, we implemented it into the Basic Printing Checklist as a best practice. Before you start a new print, check the last time maintenance was performed, or firmware was updated, and perform any of the tasks that are due. -

Page 32: Verify Material Type, Quantity, And Nozzle Configuration

The same applies for materials that have not been recommended for use by TRAK. We qualify materials by performing tests, as well as printing extensively with it, in order to understand the best printing practices, and any troubleshooting that may be required, to better help you if you encounter any issues while printing. - Page 33 When printing, you must install the correct nozzle diameter size based upon the slicer settings. Failure to install the correct nozzle size may result in bad prints, and/or printer downtime. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

-

Page 34: Wolfbite

NOTE – For customer facing parts, where surface finish is critical, TRAK recommends changing the WolfBite after every print. Reusing the WolfBite from the last print can sometimes leave a faint mark on the bottom of the newly printed part. See image to the right. - Page 35 • You may also use isopropyl alcohol, as a good alternative to help speed the process up. 5. Dry glass plate thoroughly. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

-

Page 36: Material & Nozzle Change Procedures (If Needed)

4. Then, press DONE. 5. Pre-heating will begin, and you will see “PRE-HEATING” flashing in the screen. Once preheated, the flashing sign will go away. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... - Page 37 Filament Control. NOTE - Feeder will not operate under 175°C. 6. If needed, remove the top window for better access to the feeder port. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

- Page 38 In the event that the filament is jammed, see section 7.5. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

- Page 39 A bad prime will result in the filament coiling up at the nozzle tip, bubbling up and/or not flowing consistently, or at all. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

- Page 40 NOTE – It is best practice to store the unused filament in a sealed bag with desiccant. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

- Page 41 NOTE – If the nozzles are not tightened correctly, filament will begin to ooze out between the nozzle and the print head, leading to print issues. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

-

Page 42: Printing

Using soluble supports is hands-free and doesn’t require further sanding and polishing to remove the marks left by supports. This process can be time-consuming TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... - Page 43 You may choose other types of post-processing, which include sanding, gluing, painting and inserts. Specific procedures and steps depend on your individual part needs and requirements; therefore, we have not included any procedures. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

-

Page 44: Maintenance

5. Start a print and check the relation of both nozzles. 6. If necessary, pause the print, and repeat steps 1-5. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 45: Modular Extruder Replacement

NOTE – Grab the plugs, NOT the wires (plugs will be tight). TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... - Page 46 9. Repeat in reverse order to install new extruder assembly 10. Before resuming operation of the printer, follow the Leveling Nozzle procedure found in section 6.1. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

-

Page 47: Fan Housing Removal / Replacement

7. Remove the front cover. 8. Carefully pull the fan off and separate the 4-pin connector. 9. Repeat in reverse order to install new fan housing. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 48: Feeder Removal / Replacement

4. Repeat in reverse order to install new feeder assembly. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 49: Clean Bed Rails

5.5 Clean Bed Rails TRAK recommends cleaning your bed rails every 100 print hours for more accurate auto-leveling. Steps Images 1. Cool down printer components. WARNING! Not allowing printer to cool down properly can result in serious burns. 2. Place printer in SERVICE MODE. -

Page 50: Replace Hepa Filters

5.7 Replace HEPA Filters TRAK recommends replacing your HEPA Filter every 1000 hours of print time, to reduce the VOCs and UFPs while printing. Steps Images 1. Clear the build plate. 2. Select CONTROL. 3. Use the Z-Axis pointer on the far right of the screen, to move the Z-axis to the top of its travel. -

Page 51: Borosilicate Glass Build Plate

See section 7.3 in the event that you are experiencing issues with the first layer being too close or too far from the build plate. 5.10 Lubricate Z Stage Ballscrew TRAK recommends lubricating your Z Stage Ballscrew every 1000 hours. • White lithium grease is recommended. •... -

Page 52: Troubleshooting

6. Press PRIME. PRIME will slowly feed new filament into the feeder. CAUTION – Do not press LOAD, as it will force new filament in too fast and potentially jam. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 53: Auto-Leveling Errors

• If printing too close to the bed - Select a letter closer to G. • If printing too far from the bed, select a letter closer to A. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 54: Layer Shifting

7. Repeat until filament exits tip of nozzle. 8. If filament will not extrude, press REMOVE, and see procedure in the following section. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... -

Page 55: Additional Filament Jam Procedure

6. Remove the front cover. NOTE – It is not necessary to remove fan connection, but you may if you’d like. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual... - Page 56 In this instance, the jam was at the entrance to the hot end. 11. Once cleaned, replace the feeder assembly and the cover in reversed order. TRAK Machine Tools Southwestern Industries, Inc. Airwolf EVO 3D Printers - Installation, Printing, Maintenance & Troubleshooting Manual...

- Page 57 12. Power the printer back on. 13. Test that the jam has cleared, by loading filament and priming. 14. If this did not clear the jam, please contact TRAK’s Customer Service for further assistance. TRAK Machine Tools Southwestern Industries, Inc.

-

Page 58: Trak Warranty Policy

TRAK Machine Tools Southwestern Industries, Inc TRAK Warranty Policy Warranty TRAK products are warranted to the original purchaser to be free from defects in workmanship and materials for the following periods: Product Warranty Period New TRAK/ProtoTRAK 1 Year New 3ntr...

Need help?

Do you have a question about the Airwolf EVO-T and is the answer not in the manual?

Questions and answers