Summary of Contents for REGULA 7517A

- Page 1 Certified Quality Management System HARDWARE AND SOFTWARE SYSTEM FOR FORENSIC EXAMINATION OF FIREARMS AND AMMUNITION SERIAL NUMBERS REGULA 7517. MAGNETO-OPTICAL DEVICE REGULA 7517A USER’S GUIDE Regula Ltd. 2017...

-

Page 3: Table Of Contents

CONTENTS ABBREVIATIONS ........... . . 4 INTRODUCTION . -

Page 4: Abbreviations

ABBREVIATIONS MCAS — magnetic copying accessories set — magneto-optical image — magneto-optical visualization MOV USB device — USB device for magneto-optical visualization — optic-mechanical block — magnetic tape SPRK — spare parts and repair kit — combination magnetic scanner... -

Page 5: Introduction

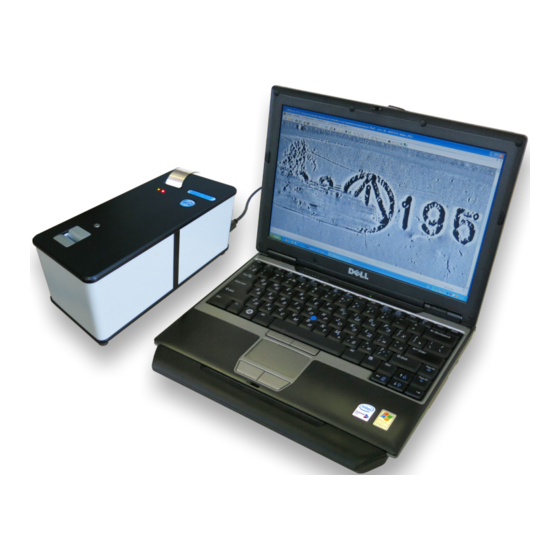

The User’s Guide is the main operational document to the magneto-optical device Regula 7517A (hereinafter referred to as the “device”). The device is a part of the hardware and software system for forensic examination of firearms and ammunition serial numbers Regula 7517. -

Page 6: Description And Operation

Regula 7517A is a set of hardware and software products enabling visualization (video imaging) of relief and structural inhomogeneity of metal surface with magnetic properties... - Page 7 Power consumption USB device for not more than 2,5 W magneto-optical visualization Reliability Time to failure not less than 10 000 hours Mean lifetime not more than 5 years Operation warranty period 12 months from the date the device is delivered to the customer Storage warranty period 12 months...

-

Page 8: Delivery Set

Magnetic clamps for magnetic tape case Container for alcohol (10 g) Brush — Marker — Case for accessories Bag for accessories **Peripheral examination tools Regula 7516 body-case Regula 7516 Software CD folder — — CD 1 **PC drivers and utilities... -

Page 9: Configuration And Operation

** — supplied optionally. 1.1.4 Configuration and Operation Regula 7517A is a set of hardware components and software products. The device allows examining objects using different methods. Examination starts with magnetic copying (making a magnetogram = magnetic copy) of the ferromagnetic object surface. The magnetic copying accessories set (MCAS) contains... -

Page 10: Means Of Measurement, Tools And Accessories

A set of operational documents contains data on design, principles of operation, properties of the device and its components. It also contains instructions on correct and safe device operation and evaluation of its technical condition when deciding whether it is necessary to send it for repairs. -

Page 11: Marking

Figure 2 Photo of the test-object examined surface Alterations of digit “6”. The original number fragment bearing digit “6” was dismantled (cut out), rotated by 180°, pressed in (so that digit “6” transformed into digit “9”) and then was fixed in the plate frame by spot welding. Digit “4”... - Page 12 Technical Specifications Material of the examined object ferromagnetic MT width 25,4 and 12,6 mm MT maximum length unlimited MT examined width not less than 20 mm Physical size of an image dot (frame format 1280×1024) 16 μm not more than for detailed examination (spatial resolution 80 μm) Acceptable thickness 0,1 mm of nonmagnetic coating...

-

Page 13: Magnetic Copying Accessories Set (Mcas)

State indicators of the MOV USB device: — “device is passive” (special software is not operating with the device), — “device is active” (special software is operating with the device), — “MT in the bunker” (insertion or extraction of MT), —... -

Page 14: Personal Computer (Pc)

CMS sleeve gaskets. 1.2.3 Personal Computer (PC) Function The PC with special software manages various USB-devices of Regula 7517A (MOV, optical input), displays operative and stored information, provides conditions for its processing, examination and documenting. Technical specifications The device can operate with a desktop PC or with a laptop. -

Page 15: Software

NUCA (EYER) is intended for input and processing of magneto-optical images of examined surface relief and structure. The software performs the following functions: operating Regula 7517A components, input of images from the scanners, automatic panoramic stitching of images of serial numbers,... -

Page 16: Intended Use

INTENDED USE Device Intended Use 2.1.1 Safety measures and operating limitations IT IS STRICTLY PROHIBITED TO: use ungrounded mains sockets, use faulty mains sockets and power supply sources, use power supply sources different from the ones described in paragraph 1.1.2, switch on the device with visible damage of protective isolation, of cables conductors and of power supply cords, switch on the device when protective shrouds are removed. -

Page 17: Intended Use Of Device Components

It is possible to examine ferromagnetic materials only (iron, steel, cast iron). Nonferromagnetic materials (aluminum) are examined with the corresponding scanner of the eddy-current magnetographing device Regula 7517B. Do not use damaged MT (having breaks with sharp edges, strongly crumpled), MT with bent on edges or dirty MT (see paragraphs 2.2.2.2 and 3.2). - Page 18 Figure 4 Magneto-optical visualization of the test object surface through the layer with thickness of 0,1 mm. Spatial resolution is around 80 μm. 2.2.1.3 MOV USB device intended use The MOV USB device performs the following operations: magnetic copy stitching, extracting a used magnetic copy, processing and analyzing magnetic copy stitching, documenting examination results.

-

Page 19: Magnetic Copying Accessories Set

Processing and analyzing magnetic copy stitching Rotate the stitched copy to match the original, using manipulation functions: image rotation and mirror imaging. Evaluate the quality of stitching visually. If the quality is satisfactory, save the initial file and start processing and analyzing. If the quality is unsatisfactory, repeat magnetic copy stitching or make a new magnetic copy. - Page 20 The order of refilling Consumables: MT, ethyl alcohol. To fill up the operating reserve of MT, do the following: take MT from the SPRK, cut it into strips of necessary length and enclose them into the cartridge intended for storing MT (Fig. 6, pos. 1). To cut metal MT, use the cutter from the SPRK and do the following: Set the cutter lever (Figure 5, pos.

- Page 21 Tear the tape along the blade edge (Figure 5, pos. 2). When tearing, it is better to “twist” the tape but not pull it up (Figure 5b). When tearing the MT avoid fins forming on strip edges. Put the obtained MT strip with its concave edge under the blade of the cutter and tear another edge similarly.

- Page 22 If the ends of the MT strip (20–30 mm from the strip ends) have transverse bends with the radius of curvature less than 20 mm (Figure 7a), straighten them. To straighten the tape, roll the tape into a tight tube of inverse curvature or slightly stretch it on an angular edge (for example, on the table edge).

- Page 23 Non-observance of the recommended form of MT strip edges can result in stitching discrepancies and MT jamming in the MOV USB device. Use of polluted and damaged MT leads to device malfunction. To renew ethyl alcohol operating reserve, take the container for alcohol from the box (Figure 7d), remove the cap, unscrew the head and pour about 5 ml of ethyl alcohol.

- Page 24 Figure 8 5 — flat concentrator, 1 — demagnetizer drive button, 6 — MT strip, 2 — frame handle, 7 — rotary concentrator screw. 3 — rotary concentrator holder, 4 — rotary concentrator, Demagnetizing MT using the CMS Magnetic copying Fix one end of the demagnetized MT strip with a magnetic clamp (Figure 9, pos.

- Page 25 Similarly fix the other end of the MT with a magnetic clamp (see Figure 9–10). MT can also be fixed on the examined surface manually — without using magnetic clamps. Figure 10 а) Making a magnetic copy of a number platform using the compact magnetic scanner with the spring clip positioned along the number platform ...

- Page 26 Remove the MT strip with the examined object copy and disconnect the magnetic clamps. Avoid contact of magnetic clamps and the scanner with the MT surface. Otherwise, the MT can be partially demagnetized or “unnecessary” magnetization elements (blemishes or strips unrelated to the examined object) may appear. Put the magnetic copy into the corresponding cartridge for storing MT (see Figures 6a, b).

-

Page 27: Maintenance Of The Device Components

MAINTENANCE OF THE DEVICE COMPONENTS MOV USB Device Daily maintenance of the MOV USB device involves the following procedures: external inspection (visually check the integrity of controls and indicators; check the USB cable isolation and connectors), checking the PC battery charge via the OS or with the help of NUCA (EYER) software in the menu “Operation / Device operation / Power sources”, cleaning the front panel and controls from dust and oily films with soft tissue or a wad wetted in ethyl alcohol (rate of alcohol application —... -

Page 28: Routine Repairs

ROUTINE REPAIRS General Instructions The list of possible problems and troubleshooting is given in Table 2. Table 2 Device Problem Cause Troubleshooting MOV USB device When connecting The USB connector Check the power cable the device to the USB has not been connection: unplug it and then port of the PC, the successfully... - Page 29 the MT edges will stick out. Thus, the User won’t be able to extract the MT strip manually without assistance. It is advised to apply to the service center. If the foreign object is still in the tract (after extracting the MT strip), the user may try to take it out using a strip of cartridge paper or thin cardboard (holding the button of the pressing roller block).

-

Page 30: Storage

STORAGE The device is to be stored in manufacturer’s packaging. Climatic storage conditions: air temperature from +5 °С to +40 °С relative air humidity up to 80 % at the temperature of +15 ˚C atmospheric pressure 100 +/- 4 KPa (750 +/- 30 mm Hg) When preparing the device for storage, it is recommended to perform maintenance works as described in paragraph 3.2. -

Page 31: Acceptance Certificate

ACCEPTANCE CERTIFICATE (to be completed by the manufacturer) Hardware and software system for forensic examination of firearms and ammunition serial numbers Regula 7517. Magneto-optical device Regula 7517A № _______________ is produced and accepted in accordance with obligatory requirements (serial number) of state standards, current technical documentation and considered serviceable. - Page 32 1 Volokha Street, Office 314, Minsk, 220036, Republic of Belarus Phone: +375 17 2862825 Fax: +375 17 2136897 e-mail: mail@regula.by http://www.regulaforensics.com...

Need help?

Do you have a question about the 7517A and is the answer not in the manual?

Questions and answers