Table of Contents

Advertisement

M00004AG - ENGLISH

Cod.

ATEX SUPPLEMENT

Type

to the User and Maintenance Manual

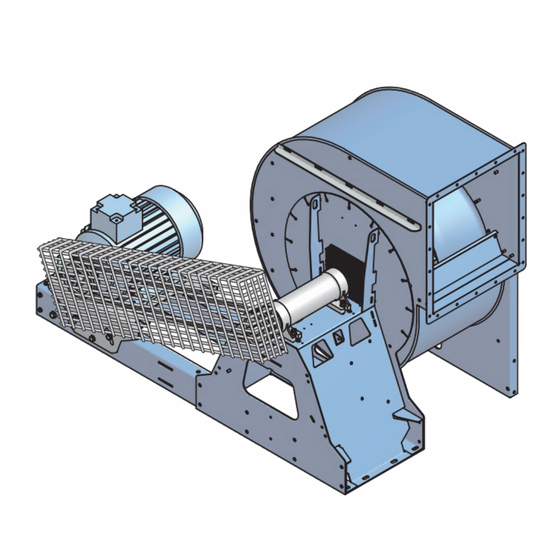

Centrifugal fan

Mod.

CH - K - SMX - Z - H

Belt transmission

"TRANSLATION OF THE ORIGINAL INSTRUCTIONS"

Caution: Operators must read the manual

and carefully follow the instructions reported

in it. The Manufacturer shall not be liable

for injury caused to people and/or daamge

caused to propery or undergone by the prod-

uct in the event of failure to comply with the

conditions below.

Coupled with

a transmission

joint

Coupled di-

rectly

Advertisement

Table of Contents

Summary of Contents for CBI CH Series

- Page 1 M00004AG - ENGLISH Cod. ATEX SUPPLEMENT Type to the User and Maintenance Manual Centrifugal fan Mod. CH - K - SMX - Z - H Belt transmission Coupled with a transmission joint Coupled di- rectly “TRANSLATION OF THE ORIGINAL INSTRUCTIONS” Caution: Operators must read the manual and carefully follow the instructions reported in it.

- Page 2 M00004AG - ENGLISH Cod. ATEX SUPPLEMENT Type to the User and Maintenance Manual Centrifugal fan Mod. CH - K - SMX - Z - H Belt transmission Coupled with a transmission joint Coupled di- rectly “TRANSLATION OF THE ORIGINAL INSTRUCTIONS” The manual is an integral part of the product and should always be made available to the users.

-

Page 3: Table Of Contents

remise Contents remise ......................2 Contents ........................... 2 Analytical index ........................ 4 GENERAL CONSIDERATIONS ..............5 ield of application ..................6 Non authorised use ......................6 eatures ....................... 7 SPECIFICATIONS ..................7 Field of use of the manual ....................7 ATEX reference standards .................... - Page 4 remise tart-up ...................... 15 CHECKS wITH THE FAN STATIONARy ..........15 Checking the distance between the impeller and nozzle (air gap) ......... 16 CHECKS wITH THE FAN RUNNING ............17 Speed of the impeller ..................... 17 Fan flow rate and partialisation of the flow..............17 First start-up ........................

-

Page 5: Analytical Index

remise Analytical index earth resistance checks ..........14 explosion-proof (ATEX) checks ............14 plate ..............11 use ..............6 plates plates .............. 11 residual risks characteristics of the fluid .......10 ducting ............13 electromagnetic interference......13 environmental conditions ........10 open intake .............13 speed of rotation checks .............17 support and requests for spare parts.....21 temperature... -

Page 6: General Considerations

remise GENERAL CONSIDERATIONS The fans conforming to the ATEX directive differ from stand- ard fans as they are built with special precautions in order to make them suitable to be used in poptentially explosive environments. In addition to the particular construction of the fan, particular monitoring and maintenance are critical so as to maintain the fan safety requirements over time and for its suitability for use in the potentially explosive environment it is placed in. -

Page 7: F Ield Of Application

ield of application General information The Manufacturer refuses any liability for any damage originating from incorrect or unwise operations. It is strictly forbidden and dangerous to use the product for different uses from those provided within the field of application. Normally intended use This fan was designed to: Product a flow of air, gas or steam by increasing their pressure,... -

Page 8: F Eatures

eatures SPECIFICATIONS Field of use of the manual This manual applies to the centrifugal fans of the following ATEX version series: Type Series CHAT CHBT Fluid Type Series Fluid Type/Series: Models available in different size configurations, orientation, direct coupling or joint or belt transmission. Treated fluid: G = Gas, D = Dust. -

Page 9: Categories Of Constructive Safety

eatures Categories of constructive safety The potentially explosive atmosphere can be caused by: - Gas, potentially explosive vapours and mists. - Dust, potentially explosive dust. - Gas and Dust, both. Depending on the duration of the potentially explosive atmosphere and its type, the risk areas are defined and shared with the customer;... - Page 10 eatures The INTERNAL and EXTERNAL CATEGORY of the fan can be different accord- ing to the different risk AREA INSIDE or OUTSIDE the fan. The basic rule between the INTERNAL and EXTERNAL category is as follows: - For fans that are not fully ducted, consider the same CATEGORY of the fan. - For fully ducted fans but in closed or poorly ventilated environments, consider the same CATEGORY of the fan.

-

Page 11: Conditions Of Installation And Use

eatures CONDITIONS OF INSTALLATION AND USE: Do not install, switch-on or perform maintenance on the fan and/or ancillary equipment if not completely certain that you are aware of and have the appropriate requirements concerning ATEX products. The fan operating data and nominal performance ratings are indicated in the relevant job documents and summarised in the attachment Ex. -

Page 12: Product Identification

eatures Product Identification The identification plate reports the serial number, some important data and the CE logo. The plates must NOT be removed or concealed under any circumstances. Another plate is installed in addition to the products suitable for explosion-proof environments (ATEX). ATEX products code reading key Example The fans are marked in accordance with the require-... -

Page 13: Ec Declaration Of Conformity

‐Monza (MB), Via della Taccona 77 ‐ Italy ‐Cambiago (MI), Viale delle Industrie 22 – Italy ‐Gissi (CH), Zona industriale 62/A – Italy dichiara sotto la propria responsabilità che i ventilatori centrifughi Atex di industrie CBI delle serie: ..................... CHA, CHB, CHT, K, HD, HV, HX SB, MB, XB, ZB come descritte nel fascicolo tecnico e nei suoi allegati, depositato presso l’ente accreditato, numero accreditamento, numero di deposito fascicolo tecnico 8000307512 e come descritti nella documentazione tecnica pertinente, sono stati costruiti in conformità... -

Page 14: A Ccident Prevention

ccident prevention General information about safety Everything stated in this ATEX manual is in addition to the safety requirements on the machine and in the basic manual of the fan and/or accessory equipment. RESIDUAL RISKS An analysis on residual risks of the product was carried out as required by the Machinery Directive. -

Page 15: I Nstallation

nstallation PRECAUTIONS TO BE TAKEN Installation method The product must be installed with full knowledge of the purpose of the installa- tion and issues related to the operation of the fans, accessory equipment, place and ducting where it will be installed. In a potentially explosive explosion-proof environment (ATEX) you must consider that the installation, commission- ing, maintenance and decommissioning require special care... -

Page 16: S Tart-Up

tart-up Before starting the fan you must know what is described above and rely on skilled professionals who are aware of all the problems related to explosion-proof environments (ATEX). In addition to this manual, consider all the requirements and information described in the basic manual for your model of the fan. -

Page 17: Checking The Distance Between The Impeller And Nozzle (Air Gap)

tart-up Checking the distance between the impeller and nozzle (air gap) Complying with the distance between the impeller and the nozzle is one of the most important parameters for a fan that works in ATEX environments. These fans are thoroughly checked but you cannot exclude a shift between the impeller and nozzle during the transport, commissioning or special maintenance. -

Page 18: Checks With The Fan Running

tart-up CHECKS wITH THE FAN RUNNING Speed of the impeller The impeller rotation speed limit is specified in the job documents as well in At- tachment Ex and on the fan plate. Fan flow rate and partialisation of the flow. The flow adjustment systems must be opened and closed slowly so as to avoid the risk of generating sparks which can create the risk of explosion. -

Page 19: M Aintenance

aintenance Frequency - (time required) - Type of job Frequency per Description of service job or control hours of work INSPECTIONS Vibration control Check the vibrations by referring to the standard basic manual relevant to your fan model. The following checks are to be carried out: 3,000 h 3000 hours - (1 hour) - Measurement of vibrations with mobile instrument 24 hours continuous - (0) - Continuous measurement of vibrations with... -

Page 20: Measurement Of Impeller Rotary Speed

aintenance Measurement of impeller rotary speed Measurement of manual rotary speed A calibrated rev counter is required for the manual measurement of the rotary speed of the impeller or the transmission shaft (with a mobile instrument). Check that the detected value of the number of revs (rpm) does not differ by more or less than 5% of the nominal speed for which the fan was designed. -

Page 21: Atex Maintenance Requirements

aintenance ATEX MAINTENANCE REqUIREMENTS For the fan to function properly in a potentially explosive atmosphere, the following steps must be carried out in addition to that indicated previously and as already described in the user and standard basic maintenance manual. The frequency of the checks can be enhanced at the discretion of the user/customer in the case of particular requirements or suspicious abnormalities. -

Page 22: A Nnexes

nnexes: OBLIGATIONS AND LIABILITy The ENCLOSED documentation is intede for qualified professionals. The information in the manual is partly taken from different suppliers' original documents. Before activating and using the product, check if all the enclosed documents required for its installation, operation and maintenance are in place. - Page 23 nnexes: Table: work performed Item Pos. Type of job and/or Notes Date Operator signa- ture...

- Page 24 nnexes: Table: work performed Item Pos. Type of job and/or Notes Date Operator signa- ture...

- Page 25 nnexes: Table: work performed Item Pos. Type of job and/or Notes Date Operator signa- ture...

- Page 26 Via della Taccona, 77 20900 Monza (MB) Italy Tel. + 39 (039) 73941 Fax + 39 (039) 737125 info@industriecbi.it www.cbifans.com CBI - Service Italy Viale delle industrie, 22 20040 Cambiago (MB) Italy Tel. + 39 (039) 95.30.84.00 Fax + 39 (039) 95.30.83.91 info@cbi-service.com...

Need help?

Do you have a question about the CH Series and is the answer not in the manual?

Questions and answers

Care este debitul de aer pt ventilatorul **** eticheta din imagine .20000 mc /h ?

The airflow rate for the CBI CH Series fan is not specified in the provided context. Therefore, it cannot be confirmed if it is 20,000 m³/h.

This answer is automatically generated