Table of Contents

Advertisement

Quick Links

NICOYA LIFESCIENCES

Operation and Service Manual V1.0

Last Updated: April 14, 2016 (V1.0)

support@nicoyalife.com

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation. This device was

manufactured in Canada.

Advertisement

Table of Contents

Summary of Contents for Nicoya OpenSPR-XT

- Page 1 NICOYA LIFESCIENCES Operation and Service Manual V1.0 Last Updated: April 14, 2016 (V1.0) support@nicoyalife.com This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

-

Page 2: Table Of Contents

QUIPMENT ETUP 1.1.1 Before any Steps are Taken........................10 1.1.2 Standard Equipment Supplies ........................ 10 1.1.3 Unpacking of OpenSPR-XT™ Instrument ....................11 1.1.4 Setting up Fluidic Connections ....................... 12 1.1.5 Turning on the OpenSPR-XT ....................... 17 SPR-XT™ I ................... 20... - Page 3 ........................... 74 ENSOR LEANING .......................... 75 NSTALLING A ........................... 75 HANGING THE AMPLE CHAPTER 7: THEORY ............................78 ......................78 OCALIZED URFACE LASMON ESONANCE ............................79 INDING INETICS 7.2.1 Steady State Affinity Experiments ......................80 7.2.2 Kinetic Affinity Experiments ........................81 7.2.3 Recommended Reading .........................

-

Page 4: Safety And Preparation For Use

Serviceable Parts The OpenSPR™ and XT add-on does not include any user serviceable parts inside. Refer service to Nicoya Lifesciences Inc. Additional Safety Notes This unit has been thoroughly tested using standard biological buffer solutions such as Tris, PBS, and Citrate buffer at neutral pH. - Page 5 It is recommended that the system be connected to a surge protected power Outlet. The XT autosampler add-on must be connected to a suitable mains power supply with a correctly installed protective earth conductor. Removal of panels on the XT addon may expose users to lethal voltages. For that reason this should only be done by a qualified service engineer.

-

Page 6: Operating Conditions

12. Carefully inspect tubing and connections prior to tweezers testing. 13. The tubing in the peristaltic pump will wear over time. Contact Nicoya Lifesciences for a replacement when needed. 14. It is the responsibility of the user to ensure the safety and appropriateness of the chemicals, materials, and fluids being used in the OpenSPR™... - Page 7 16. Do not open the electronics compartment. Contact Nicoya Lifesciences Inc. if there is an electrical problem and a customer service agent will assist you. 17. Ensure tubing Outlets are fed into an appropriate waste container before turning on the pump.

-

Page 8: Specifications

Specifications Size and Weight Open SPR XT Add-on Length 216 mm Length 510 mm Width 150 mm Width 310 mm Height 120 mm Height 360 mm Weight 1 kg Weight 20 kg Electrical Specifications Open SPR XT Add-on Voltage 120/240 V Voltage 95-240 V Frequency... - Page 9 Refractive index resolution – 10 Refractive index drift per 5 min Temperature Sensitivity 6.9 x 10 RIU/ Sample Injection Fully automated, 100 µL Temperature at sensor Room temperature Temperature for sample storage 4°C - 20°C Channel Single Sample format 96-well microplates Sample capacity 2 microplates...

-

Page 10: Chapter 1: Getting Started

2. Read and follow all installation and operation instructions in this manual to ensure that the performance of this instrument is not compromised. 3. Open the boxes and inspect all components of the OpenSPR-XT™ system. 4. Report any damage to Nicoya Lifesciences Inc. immediately. -

Page 11: Unpacking Of Openspr-Xt™ Instrument

Laptop (optional) 1.1.3 Unpacking of OpenSPR-XT™ Instrument 1. Read the OpenSPR-XT™ Operation Manual. 2. Carefully remove all components from boxes. When removing the XT autosampler from its box, ensure to keep it in an upright position (it is recommended to use 2 people to do this). -

Page 12: Setting Up Fluidic Connections

Figure 1.2 Cover completely removed from the XT autosampler. 6. Remove all tape and packaging internal to the XT autosampler. 7. Place the OpenSPR™ on top of the XT autosampler such that the OpenSPR™ is covering the open slot on top of the XT and it is stable [Figure 1.3]. Figure 1.3 OpenSPR placed on top of XT autosampler in a stable position. - Page 13 Figure 1.4 How to remove sample cooling cover. 2. Fill the 250 mL Wash Bottle with a solution of 80% isopropanol (v/v in DI water). 3. Insert the Wash Bottle into the holder located on the left side of the sampling compartment, and insert the wash tube into the bottle, ensuring it reaches the bottom [Figure 1.5].

- Page 14 Figure 1.6 Insert tubes from bottom of OpenSPR down through the slot on top of the XT autosampler. 5. These two tubes will need to be connected to the valve inside of the sample chamber [Figure 1.7]. The two tubes should be labelled “1” and “6”. The tube labelled “1” needs to be connected to valve position 1, and the tube labelled “6”...

- Page 15 Figure 1.8 Close up of valve with corresponding valve positions. To connect them, two nuts and two ferrules are provided as shown in Figure 1.9. The ferrules may be opaque as shown in the figure or clear. They may already be installed on the tubing, or provided separately in a bag.

- Page 16 tightening the nut – this is essential to maintain zero dead volume. If the threads of the nut are not catching on the valve fitting, adjust the angle of the nut. To ensure that the tubing is secured to the valve, gently pull back on the tubing after the fittings have been tightened - the tubing should remain fixed in place.

-

Page 17: Turning On The Openspr-Xt Tm

Loop waste line. 1.1.5 Turning on the OpenSPR-XT 1. Install the OpenSPR-XT™ software onto your computer if a computer was not provided with your instrument. Ensure that the computer meets the specifications listed above. Follow the instructions in the “Software Installation” document (separate). The software installation files... - Page 18 2. Connect the power cable to the OpenSPR™ instrument [Figure 1.14] and plug it into an appropriate power outlet (a surge protected outlet is recommended). 3. Connect the computer to the OpenSPR™ instrument via the USB cable. Figure 1.14 - Back of OpenSPR™ instrument contains connections for power and USB cables, and power switch. 4.

- Page 19 Figure 1.16 Power LEDs located on the front of the OpenSPR and XT autosampler. 9. Start the OpenSPR-XT™ software by double clicking on the “OpenSPR” desktop icon to connect the device. 10. Read the OpenSPR-XT™ Operation Manual entirely before operation.

-

Page 20: Overview Of Openspr-Xt™ Instrument Components

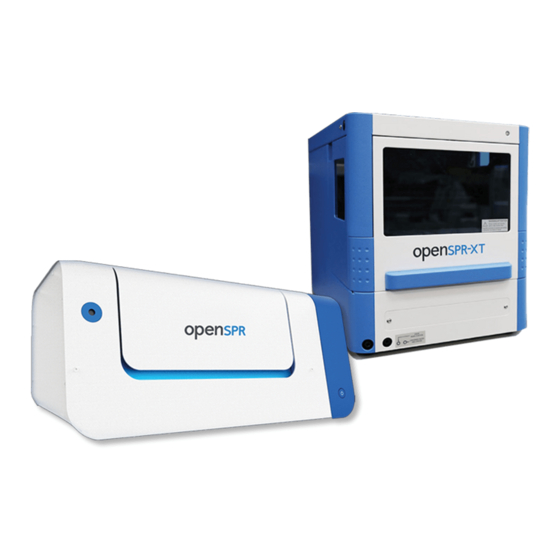

1.2 Overview of OpenSPR-XT™ Instrument Components The OpenSPR-XT™ instrument consists of an OpenSPR unit and an XT autosampler unit [ Figure ]. The OpenSPR unit contains the optical detection system, while the XT autosampler unit 1.17 contains the majority of the fluidics system as well as the sample storage area. An overview of the instrument components are described in this section, and more details on the hardware operation can be found in Section 4.1. - Page 21 (the ligand) onto the surface. There are a number of ways to do this, and Nicoya Lifescience Inc provides a variety of pre-prepared surface chemistries to ensure consistent Figure 1.19 - Sensor Chip with nanogold (red and high quality ligand immobilization.

- Page 22 Figure 1.20 - Fluidics Block and Flow Cell (left) and corresponding sample holder containing Sensor Chip (right). The XT autosampler contains the sample compartment which houses the plate holders, sampling needle, fluidics valve and fluidics washing system [Figure 1.21]. It is fluidically connected to the OpenSPR unit via the injection valve.

- Page 23 Figure 1.21. When the sample compartment door is open and the OpenSPR-XT software is running, the sample holders will come forward to the front of the XT autosampler as seen in...

- Page 24 Figure 1.24 Plate holders come forward when door is open and OpenSPR-XT software is running. The sampling needle is controlled by a robotic arm which is programmed to position the needle into the selected well of interest in either of the 96-well plates. The syringe will automatically draw the sample into the needle, load it into the sample loop, and inject it into the fluidics block of the OpenSPR unit via the injection valve.

-

Page 25: Chapter 2: Operation Guidelines

4. Switch ON the XT autosampler power switch located at the back of the instrument [Figure 1.15]. The green LED on the front of the instrument should turn on [Figure 1.16]. 5. Open the OpenSPR-XT™ program on the computer by double clicking on the program shortcut. The OpenSPR-XT™ Home Screen will open [Figure 2.1]. -

Page 26: Instrument Priming And Obtaining References

If the software still does not connect, a combination of turning the OpenSPR-XT™ devices on and off, unplugging and plugging the USB cables and restarting the software or computer may be required. - Page 27 2. Next, the software will ask if you would like to take a new reference spectrum [Figure 2.3]. Reference spectra consist of a Dark Reference and Bright Reference used to calculate the absorbance. The Dark Reference is taken with the light OFF and the Bright Reference is taken with the Light ON (without a Sensor Chip in the instrument).

- Page 28 5. Once the LED is stable, the software will capture the bright reference. You should now see a red and blue line in the main Reference graph on the screen similar to that shown in Figure 2.5. The Red line is the Bright reference and the blue line is the Dark Reference. Figure 2.5 - Reference window: Red line is the bright reference, blue line is the dark reference.

-

Page 29: Loading A New Sensor Chip

2.2.3 Loading a New Sensor Chip 1. Next, the software will prompt you to load your Sensor Chip [Figure 2.7]. Always ensure that the Flow Cell is clean of dust and debris prior to loading a new Sensor Chip. Do this by soaking a lint free wipe in isopropanol and gently wiping the Flow Cell surface. - Page 30 Figure 2.8 - How to easily remove the magnetic sample holder: 1. Remove the side closest to you using a twisting motion, 2. Pull back to remove the other side. 5. Carefully slide the Sensor Chip into the slot in the top of the Sensor Holder and ensure it is fully seated against the bottom of the holder [Figure 2.9].

- Page 31 Figure 2.10 – Placing Sensor Holder into Instrument by slowly bringing it into contact with the Fluidics Block Figure 2.11 - Properly secured sample holder onto Fluidics Block 7. After the Sensor Chip has been loaded, select “Yes” to activate the pump and fill the Flow Cell with running buffer [Figure 2.7].

-

Page 32: Bubble Removal & Cooling

Figure 2.12 - Filling Flow Cell progress bar with strong Gaussian absorbance peak of Sensor Chip. 8. After the Flow Cell has been filled, the software will automatically find and fit the absorbance peak of the sensor. The peak fit will be displayed as a green line along the curve of the absorbance peak. - Page 33 Figure 2.13 Main screen of Bubble Removal step showing Absorbance and Baseline graphs, bubble removal controls, temperature controls and XT autosampler status. 2. Next, a bubble removal injection needs to be performed to make sure the Flow Cell as well as Fluidic Lines are clear of bubbles.

- Page 34 3. Using the Autosampler menu, select the appropriate plate position (left or right) and the corresponding well on the plate to which the IPA solution was loaded [Figure 1.15]. Figure 2.15 Menus to select the appropriate plate position and well position for the IPA solution injection for bubble clearing. 4.

- Page 35 Figure 2.17 - Example of bubble present in Flow Cell microchannel. Flow Cell is being illuminated from above using an external light. If there are bubbles present, repeat steps 2-5 (this may have to be done several times). 6. When the microchannel is clear of bubbles, remove the 96-well plate from the sample compartment.

- Page 36 may take a while for the compartment to cool (at least 15 minutes to reach 4°C from room temperature), which is why this is performed prior to setting up the testing procedure. Figure 2.19 Autosampler Temperature menu. 9. Click “Next” to proceed to the next step. 10.

-

Page 37: Sample & Timeline Setup

2.2.5 Sample & Timeline setup Note: When preparing your samples, at least 300 µL of sample is required per well (for a 100 µL standard sample loop). Beware of sample evaporation if you are running a long test (> 1hr), especially if the samples are being stored at room temperature in a low humidity environment. - Page 38 Figure 2.22 Click the "Add" button in the User Samples section to load sample information. 3. This will bring up another screen where you will input your sample details as well as the well plate positions of your samples [Figure 2.23]. Figure 2.23 Sample details screen.

- Page 39 chip surface. For analyte injections, speeds between 20 – 50 µL/min are recommended (see Kinetics handbook for details). For regeneration, speeds up to 150 µL/min can be used. Figure 2.24 Sample details box. Then, click on the well positions that will contain this sample. The software allows you highlight multiple wells to input the same sample properties to more than one well.

- Page 40 Alternatively, to go back to the Test Setup screen without logging a new sample, click “Cancel” in the Sample Details box. Figure 2.26 Test Setup screen with first sample details loaded into the User Samples window. 6. Click the “Add” button again to add additional samples. Note that all user injections including ligand, blocking solutions, analyte, regeneration solutions, etc will need to be added as samples.

- Page 41 7. Once the sample details are loaded, the Test Timeline can begin to be setup. The Test Timeline will be the procedure that the XT autosampler follows. A Start event is preloaded into the timeline for you, with a 50 second delay. To add a sample injection step into the Timeline, click and drag the sample from the User Sample box into the “Next Step”...

- Page 42 Figure 2.29 To complete Test Timeline, click and drag "Finish" process to the end of Test Timeline. 9. Before proceeding, the 96 well plate(s) containing the samples specified in the Test Timeline need to be added into the Sample Compartment, such that well A1 is positioned in the front left corner of the corresponding left or right plates [Figure 2.30].

- Page 43 If a bubble is present inside the Flow Cell channel, click “Back” once more to return to the Bubble Removal Screen and repeat the bubble removal process as specific in section “Bubble Removal & Cooling”. Your sample information and Test Timeline will be saved. 11.

-

Page 44: Shut Down Procedure

ENSURE THAT THE SAMPLE COMPARTMENT DOOR REMAINS CLOSED OVER THE DURATION OF THE TEST. THE AUTOSAMPLER WILL NOT OPERATE IF THE DOOR IS OPEN AND THE TEST TIMING WILL BE INACCURATE AS A RESULT. Figure 2.33 Test screen graphing real-time data aquisition. The Test screen displays the Response graph, temperature controls as well as the autosampler status. - Page 45 5. If it is the final test of the day remember to flip the power switches off on both the OpenSPR unit and the XT autosampler.

-

Page 46: Chapter 3: Data Analysis Using Tracedrawer

Chapter 3: Data Analysis using TraceDrawer 3.1 Data Output Once an experiment is complete, several types of data files are created. An example of the output files created from a test is shown below [Figure 3.1]: Figure 3.1 - Example of output files created after a test. The corresponding file types are explained in the table below: AborbanceSpectra This folder contains absorbance spectra saved every time an... -

Page 47: Tracedrawer Analysis

3.2 TraceDrawer Analysis The procedure below demonstrates the analysis of real data from OpenSPR experiments using the most commonly used TraceDrawer functions. 3.2.1 Import data into TraceDrawer 1. Open TraceDrawer software and click Add run to import TestName_TraceDrawerExport.txt file [Figure 3.2]. Figure 3.2 - TraceDrawer start page with Add Run button highlighted. - Page 48 Figure 3.3 - TraceDrawer Add Run menu where can add run name, description, curve names and sample concentrations. Click OK to add the run. This will be shown as a thumbnail in the bottom left corner of the window [Figure 3.4]. Figure 3.4 - OpenSPR data shown as a thumbnail in the run section (bottom left corner).

-

Page 49: Data Modifications

Figure 3.5 - Create a new overlay, then left click and drag the run into the overlay window (left). Updated window with run added to overlay (right). 3.2.2 Data modifications Note: not all modifications listed below are required for every analysis. Steps 4 to 8 are the most commonly used in OpenSPR analysis. - Page 50 Uncheck irrelevant curves in overlay clone. Here, only analyte and reference curves are checked [Figure 3.7]. Figure 3.7 - Overlay clone with only binding and reference curves checked on right side of window. 5. Zoom in a. Right click on plot and press Zoom to extents to center the entire plot b.

- Page 51 Figure 3.9 - Within modification tab, select move curve option to shift the position of selected curves. Once the curves are aligned in x, it is also recommended to set the beginning of the curves to Y=0. Select all curves. Click Curve offset in Modification tab and position the bar at the x-value where the curves start (or simply enter this x-value).

- Page 52 Figure 3.12 - To crop curves at boundaries, enter Curve Axis Extents in Modification tab. Then Zoom to extents (see step 5) [Figure 3.13]. Rename the overlay if needed in Appearance tab. Figure 3.13 - Example curves after cropping and Zooming to extents. 8.

- Page 53 Figure 3.14 - Select reference curve only and apply Curve subtraction in Modification tab (Keep original curves does not need to be checked). The red reference curve appears to have a slight downward slope. The corrected blue curves show a slightly flatter dissociation compared to the original black curves [Figure 3.15]. Figure 3.15 - Corrected binding curves (blue) have slightly flatter dissociation than original curves (black) after correcting with reference (red).

-

Page 54: Kinetics Evaluation

3.2.3 Kinetics Evaluation Generally, a sugar test injection (25 mg/ml in the running buffer) is performed under the same experimental conditions to help determine the dispersion characteristic of sample injections. For example, at 20µl/min pump speed, the actual association period is around 200s as shown below [Figure 3.16]. - Page 55 11. In the Time point box, enter the time for the start of concentration change and press Add change. This can be interpreted as the X value where Y=0 before all curves start to rise. Similarly, add the end of concentration change by summing the association time period with the start time of concentration change (For example: 27s+200s=227s).

- Page 56 Figure 3.19 - Add sample concentrations at initial concentration using the curve properties (top) or manually entering the values. The start time should have the sample concentrations and the end time should be at zero. Press Next. 12. Fit model Select model from the Fit model drop down list.

- Page 57 Figure 3.21 - Fit Settings window that appears when Settings button is clicked. Ensure ka, kd and kt are set to Global. Then press Fit. A good fit will closely approximate the responses. Check show errors and scroll to the right to see Chi2 value.

-

Page 58: Additional Resources

Plot below shows the residuals of the fit model. Press Curves to return to analyte responses. Figure 3.23 - The Residuals/Curves button toggles between plots of the residuals (shown) and curves. 3.2.4 Additional Resources For a complete list of TraceDrawer functions and procedure, refer to TraceDrawer Handbook which can be accessed from the top menu in the software under Help >... -

Page 59: Chapter 4: Openspr-Xt Tm System Details

Chapter 4: OpenSPR-XT System Details 4.1 Hardware The OpenSPR-XT™ instrument consists of an OpenSPR unit and an XT autosampler unit [ Figure ]. The OpenSPR unit contains the optical detection system, while the XT autosampler unit contains the majority of the fluidics system as well as the sample storage area. - Page 60 (the ligand) onto the surface. There are a number of ways to do this, and Nicoya Lifescience Inc provides a variety of pre-prepared surface chemistries to ensure consistent and high quality ligand immobilization. See OpenSPR Kinetics Handbook for more details on the Sensor Chips.

- Page 61 with high precision in real-time. Increases in the refractive index at the sensor surface, caused by, for example, a binding event to the sensor, causes the LSPR absorbance peak to shift to higher wavelengths. Figure 4.4 - OpenSPR™ optical system diagram (top view). Note sample holder is not shown. The fluidic system is essential to introducing analyte to the sensor surface in a consistent and repeatable manner.

-

Page 62: Xt Autosampler Unit

Figure 4.6 - Cross-section (top-down) of microchannel formed between Flow Cell and Sensor Chip. 4.1.2 XT Autosampler Unit The XT autosampler comprises the sample compartment, which can be accessed through the sample compartment door [ ]. Instructions for opening the sample compartment door Figure 4.7 are given in . - Page 63 Figure 4.8 Instructions to open sample compartment door. Figure 4.9 Instructions to remove sample compartment cover. The XT autosampler also comes with a sample cooling cover that can be slid in and out from the instrument to gain access to the plate holders [ Figure 4.10...

- Page 64 The sample compartment has holders that fit two 96-well plates. The plate holders will sit in the back of the instrument when it is off or in use with the sample compartment door closed as seen . When the sample compartment door is open and the OpenSPR-XT software is Figure 4.11 running, the sample holders will come forward to the front of the XT autosampler as seen in for easier access.

- Page 65 Figure 4.12 Plate holders come forward when door is open and OpenSPR-XT software is running. The sampling needle is controlled by a robotic arm which is programmed to position the needle into the selected well of interest in either of the 96-well plates. The syringe will automatically...

- Page 66 To fill the sample loop, the valve is switched to the LOAD position [ ]. The needle Figure 4.14 continues to aspirate the sample until the entire sample loop is full. Figure 4.14 A) Switching of the Valve to LOAD position. B) Filling the sample loop completely. Once the sample loop is full, the Valve is switched to the INJECT position [ ].

-

Page 67: Software

4.2 Software 4.2.1 Adjusting the Response Graph The Response graph axis are defaulted to autoscale as the signal changes. However, it can be desirable to zoom in or out on certain areas of the graph as test progresses. The graph can be moved in the x and y axis by holding the right mouse button and dragging the mouse. - Page 68 will speed it up. It is also useful if you would like to remove previous data and easily scale the graph axis to the current data points.

-

Page 69: Chapter 5: Faq & Troubleshooting

XT™ at temperatures out of this range. Q: What pump speed is recommended? A: When initially filling the system, and baselining a new chip the OpenSPR-XT™ uses a speed of 150 μL/min. For functionalizing the sensor surface, lower speeds (20 μL/min) are recommended to allow ligand immobilization/capturing to occur. - Page 70 Buffer does not flow through Flow Cell: Remove the Flow Cell and look for ripping of the material at the Inlet and Outlet. Dislodge any material in the Inlet/Outlet with blunt tip needle or something similar. Once removed, reassemble and look for leaks. Bubble(s) present in Flow Cell: The presence of a bubble in the Flow Cell will usually correspond to an extremely sharp change in the peak wavelength, a sudden jagged edge along a binding curve, or a very unstable baseline.

- Page 71 The user must be careful of leaks as the OpenSPR-XT™ is not waterproof. When a leak is suspected, check to see if the sample holder is properly aligned and seated tightly. If so, disassemble the sample holder to see if the Flow Cell is seated properly and if there are tears in the Flow Cell material near the Inlet and Outlet.

-

Page 72: Chapter 6: Cleaning And Maintenance

Chapter 6: Cleaning and Maintenance 6.1 Start-up and Diagnostic Routines 1. The first time operating OpenSPR-XT™, or after a new Flow Cell is installed, the instrument should be run with buffer at maximum pumping speed for 30 minutes to ensure no leaks are present and ensure that there are no bubbles being introduced into the fluidic pathway. -

Page 73: Instrument Maintenance And Cleaning

Figure 6.2 - Examples of bad sugar injections where bubbles were present in valve or flow cell. 6.2 Instrument Maintenance and Cleaning To prevent clogging or contamination in future experiments it is recommended that deionized water be pumped through the system after the day’s experiments are completed to prevent salt build up in the lines. -

Page 74: Sensor Chip Cleaning

Finish This procedure provides the required 10 minutes between each injection necessary for proper cleaning of the instrument. 5. Begin the test procedure after water has been flowing through the system for at least 15 minutes. 6.3 Sensor Chip Cleaning Organic contaminants can accumulate on the sensor surface in storage over time that may affect the sensitivity of the sensor. -

Page 75: Installing A New Flow Cell

6.4 Installing a New Flow Cell The OpenSPR-XT™ instrument comes pre-installed with a Flow Cell. However, over time the Flow Cell may wear and need cleaned or replaced. 1. To remove a Flow Cell, insert tweezers behind the Flow Cell near the barbed fitting. Gently use the tweezers to slowly pull the Flow Cell off of the barbed fittings. - Page 76 Figure 6.3 - Sample Loop and connectors 1. Ensure the OpenSPR and XT autosampler units of the OpenSPR-XT instrument are ™ powered off. 2. Remove the Sample Compartment Cover of the XT autosampler following the procedure outlined in . This will allow you easier access to the valve.

- Page 77 Figure 6.5 Location of the valve and Sample Loop inside the sample compartment. 4. Remove the plastic covers from both ends of the new Sample Loop. 5. Slide the nuts onto the ends of the Sample Loop followed by the ferrules in the orientation shown in Figure 6.6.

-

Page 78: Chapter 7: Theory

Chapter 7: Theory 7.1 Localized Surface Plasmon Resonance OpenSPR™ is a label free biosensing platform that utilizes localized surface plasmon resonance (LSPR) to make extremely sensitive measurements of biomolecular interactions. LSPR is an optical phenomenon that occurs when light is absorbed by noble metal nanoparticles. These particles are typically on the order of 10 –... -

Page 79: Binding Kinetics

RI that occur within this distance. This feature along with the sensitivity of the nanoparticles, which is also dependent on their shape, allows Nicoya Lifesciences Inc to tailor the performance of the sensor directly to the biomolecular system of interest, thus maximizing performance. -

Page 80: Steady State Affinity Experiments

�� [ ���� ] [ �� ][ �� ] − �� [ ���� ] = 0 = �� �� �� ���� [ �� ][ �� ] �� �� = �� �� [ ���� ] �� �� Where K is the equilibrium dissociation constant defined in concentration units i.e. moles/litre. In defining the system this way, a quick quantification of the strength of the binding interaction can be stated simply by reporting the order of magnitude of the K value. -

Page 81: Kinetic Affinity Experiments

7.2.2 Kinetic Affinity Experiments There are some limitations that may make steady state experiments undesirable. For strong interactions, the amount of analyte required to reach steady state conditions may be excessive. Also, steady state experiments can be used to determine equilibrium constants K and K not the binding constants k and k... -

Page 82: References

Myszka DG (1999) Improving biosensor analysis, J. Mol. Recog. 12: 279-284. Rich RL & Myszka DG (2009) Extracting affinity constants from biosensor binding responses in Label-Free biosensors: Techniques and Applications (MA Cooper, Ed.; Cambridge Univ. Press) pp 85-109. ...