Summary of Contents for Rohde & Schwarz TS7124AS

- Page 1 ® R&S TS7124AS RF Shielded Box Instructions Handbook (;ÝM`2) 1179294802 Version 01...

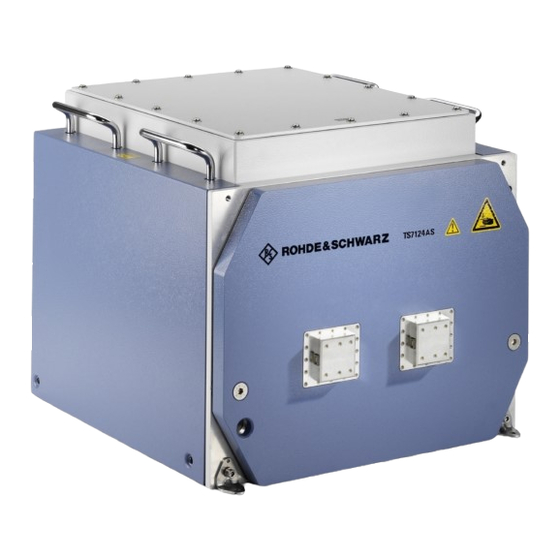

- Page 2 ® R&S TS7124AS (order no. 1525.8587.12) with two front feedthrough ports The RF Shielded Box is also referred to as the "chamber" or the "product". The firmware of the instrument uses several valuable open source software packages. For information, see the "Open Source Acknowledgment"...

-

Page 3: Table Of Contents

® Contents R&S TS7124AS Contents 1 Introduction.................... 7 Regulatory Information....................7 1.1.1 CE Declaration........................ 7 1.1.2 China RoHS Certification....................7 Documentation Overview..................... 7 1.2.1 Instructions Handbook....................8 1.2.2 Configuration Manual...................... 8 1.2.3 Data Sheets and Brochures.................... 8 1.2.4 Open Source Acknowledgment (OSA)................8 1.2.5... - Page 4 ® Contents R&S TS7124AS Storage.........................23 6 Installation and Commissioning............24 Choosing the Operating Site..................24 Unpacking........................25 Mounting the Chamber....................26 6.3.1 Table Mounting......................27 6.3.2 Rack Mounting......................28 Connecting Compressed Air..................31 Connecting to Control and Power................33 Testing Safety Systems....................37 Defining Zones of Restricted Access................38 Adjusting the Door Speed..................

- Page 5 ® Contents R&S TS7124AS 9.4.2 Checking the Absorber....................57 9.4.3 Cleaning the Chamber....................57 9.4.4 Cleaning the Gasket......................58 9.4.5 System Calibration......................58 10 Troubleshooting and Repair............... 59 10.1 Door Error........................59 10.2 Controller Conflicts.....................59 10.3 Contacting Customer Support...................61 11 Disabling and Scrapping..............62 11.1...

- Page 6 ® Contents R&S TS7124AS Instructions Handbook 1179.2948.02 ─ 01...

-

Page 7: Introduction

1.2 Documentation Overview This section provides an overview of the R&S TS7124AS user documentation. Unless specified otherwise, you find the documents on the R&S TS7124AS product page at: Instructions Handbook 1179.2948.02 ─ 01... -

Page 8: Instructions Handbook

® Introduction R&S TS7124AS Documentation Overview www.rohde-schwarz.com/product/ts7124 1.2.1 Instructions Handbook This handbook contains the description of all operating modes and functions of the chamber. It also provides an introduction to remote control, a complete description of the remote control commands, information on maintenance, interfaces and error mes- sages. -

Page 9: Application Notes, Application Cards, White Papers, Etc

These documents deal with special applications or background information on particu- lar topics. www.rohde-schwarz.com/application/ts7124 1.3 Conventions The R&S TS7124AS Shielding Cube mmW is also referred to as the "chamber" or the "product". The following text markings are used throughout this handbook: Convention... -

Page 10: Safety

® Safety R&S TS7124AS Residual Risks 2 Safety Products from the Rohde & Schwarz group of companies are manufactured in accord- ance with the highest technical standards. Follow the instructions provided throughout this handbook. Keep the product documentation nearby and offer it to other users. -

Page 11: Potentially Dangerous Situations

® Safety R&S TS7124AS Potentially Dangerous Situations Door of the chamber is heavy The center of gravity moves with the door when you open it. If the chamber topples, it can cause severe injuries, even death. If the chamber sits on rails in a rack, the shift of the center of gravity is enhanced when you slide the chamber out of the rack and open the door at the same time. - Page 12 ® Safety R&S TS7124AS Potentially Dangerous Situations Without gloves, you have less friction and your grip can slip if your hand is oily or wet. As a result, the chamber can drop and crush your foot or someone else's. Therefore, always wear safety shoes with toe cap when moving the chamber.

-

Page 13: Warning Messages In This Handbook

® Safety R&S TS7124AS Warning Messages in This Handbook appliances and similar loads. Be aware of electrical risks, such as electric shock, fire, personal injury or even death. Take the following measures for your safety: ● Before connecting the power supply unit to a power source (your mains grid), ensure that this source matches the voltage and frequency [INPUT] range indica- ted on the power supply unit. -

Page 14: Labels On The Chamber

® Safety R&S TS7124AS Labels on the Chamber WARNING Potentially hazardous situation Could result in death or serious injury if not avoided. CAUTION Potentially hazardous situation Could result in minor or moderate injury if not avoided. NOTICE Potential risks of damage Could result in damage to the supported product or to other property. -

Page 15: Emergencies

® Emergencies R&S TS7124AS Automatic Emergency Deactivation 3 Emergencies Possible emergencies can result from a failure of the soft-close mechanism that stops the door, if an obstacle prevents closing, see Automatic Emergency Deactivation. But if the soft-close mechanism fails and you have your hands in the way of the closing door, your hands can get caught between the door and the chamber's frame. -

Page 16: Automatic Emergency Deactivation Due To Timeout

® Emergencies R&S TS7124AS Automatic Emergency Deactivation 3.2.1 Automatic Emergency Deactivation Due to Timeout If the door does not open or close within the period, the control system TIMEOUT switches to ERROR mode and automatically depressurizes the pneumatic system, leav- ing the door forceless. -

Page 17: Machine Overview

® Machine Overview R&S TS7124AS Front Tour 4 Machine Overview This chapter describes all components of the chamber. Function and use of these com- ponents is described in Chapter 7, "Operation", on page 42. Accessories for the chamber are described in the Configuration Manual. - Page 18 ® Machine Overview R&S TS7124AS Front Tour The polymeric gasket (2) has a conductive nickel coating to prevent leakage of RF radiation out of the chamber, and into it. Avoid touching or soiling the gasket. The front door's gasket is highly elastic for a long life over many opening and closing cycles, see Chapter 5.5,...

-

Page 19: Rear Tour

® Machine Overview R&S TS7124AS Rear Tour 4.2 Rear Tour Figure 4-3: Rear view of the chamber 1 = Top cover for interior configuration and service (only for expert users) 2 = Numbered RF feedthrough connectors for antennas inside the chamber (only for expert users) 3 = Supply and control panel, see Chapter 6.5... -

Page 20: Push-Button Switch Unit

® Machine Overview R&S TS7124AS Push-Button Switch Unit 4.3 Push-Button Switch Unit The push-button switch unit is an optional manual control device for opening and clos- ing the chamber at the push of a button, as described in Chapter 7.3.2, "Push-Button Door Operation",... -

Page 21: Transportation, Handling And Storage

® Transportation, Handling and Storage R&S TS7124AS Packing 5 Transportation, Handling and Storage Familiarize yourself with residual risks and potentially dangerous situations. Chapter 2.2, "Residual Risks", on page 10 and Chapter 2.3, "Potentially Danger- Situations", on page 11. ● Lifting and Carrying.................... -

Page 22: Securing

® Transportation, Handling and Storage R&S TS7124AS Securing 5.3 Securing When delivered, the chamber is contained in a special transport protection packaging that prevents the door from opening. After unpacking, to prevent unintentional movement of the door, an additional safety... -

Page 23: Transport

® Transportation, Handling and Storage R&S TS7124AS Storage 2. Lift the chamber as described in Chapter 5.1, "Lifting and Carrying", on page 21. Note: If you proceed with mounting and operating the chamber, we recommend that after mounting, you remove (and not only rotate) the safety latch. -

Page 24: Installation And Commissioning

® Installation and Commissioning R&S TS7124AS Choosing the Operating Site 6 Installation and Commissioning The following activities are restricted to the maintenance personnel. Familiarize yourself with residual risks and potentially dangerous situations. Chapter 2.2, "Residual Risks", on page 10 and Chapter 2.3, "Potentially Danger-... -

Page 25: Unpacking

® Installation and Commissioning R&S TS7124AS Unpacking Electromagnetic compatibility classes class indicates where you can operate the chamber. ● Class B equipment is suitable for use in: – Residential environments – Environments that are directly connected to a low-voltage supply network that supplies residential buildings ●... -

Page 26: Mounting The Chamber

® Installation and Commissioning R&S TS7124AS Mounting the Chamber 10. Retain the original packing material. Use it when transporting or shipping the chamber later. 11. Using the delivery notes or an accessories list, check the delivery for complete- ness. 12. Check the chamber for damage. - Page 27 ® Installation and Commissioning R&S TS7124AS Mounting the Chamber 6.3.1 Table Mounting Use a support that meets the requirements. Make the support robust and safe. To mount the chamber on the support 1. WARNING! The door of the chamber is heavy and can move. If the door slides open while you lift the chamber, the center of gravity shifts.

-

Page 28: Rack Mounting

® Installation and Commissioning R&S TS7124AS Mounting the Chamber If you remove the chamber from its location, follow the instructions in Chapter 5.1, "Lift- ing and Carrying", on page 21. 6.3.2 Rack Mounting With the optional rack mounting kit R&S TS-F24-Z1 (order no. 1526.6942.02), you can mount the chamber in a standard 19'' rack. - Page 29 ® Installation and Commissioning R&S TS7124AS Mounting the Chamber Figure 6-4: Cage nuts for metric M5 screws (not included in the delivery) Start with the chamber unpacked and transported to the operating site, but not yet positioned and mounted on a support.

- Page 30 ® Installation and Commissioning R&S TS7124AS Mounting the Chamber Figure 6-5: Set of torx screws and washers, included in the rack mounting kit 1 = Large washers, small spring-lock washers and M6 x 12 screws (4 each) for fixing the metal sheet to...

-

Page 31: Connecting Compressed Air

® Installation and Commissioning R&S TS7124AS Connecting Compressed Air 2b = Grounding socket. Insert from the rear side of the metal rack cover sheet 3 = Metal rack cover sheet 4 = Detail: M5 screw and small washer (2a) inserted from the front side and grounding socket (2b) inserted from the rear side of the cover sheet 9. - Page 32 ® Installation and Commissioning R&S TS7124AS Connecting Compressed Air ● The compressed air is supplied by a flexible push-in tube with a diameter of 6 mm. If the tube has a straight cut end, it is easier to connect it.

-

Page 33: Connecting To Control And Power

The DC power socket and the control interfaces are at the rear of the chamber. Figure 6-9: Detail views of the left and right arrays of supply and control connectors and control screws on the rear side of the R&S TS7124AS 1 = Control screw for door opening speed, see Chapter 6.8, "Adjusting the Door... - Page 34 ® Installation and Commissioning R&S TS7124AS Connecting to Control and Power 5 = Connector [X26] (RS-232, 9-pin D-Sub, female) for remote door control via a serial port 6 = Connector [X32] (binder socket, 3-way, female) for monitoring the door status...

- Page 35 ® Installation and Commissioning R&S TS7124AS Connecting to Control and Power a) Remove the safety cap (Figure 6-10) from the control connector [X21] on the rear side of the chamber. Figure 6-10: Safety cap, covering the D-Sub 25-pin connector [X21] b) Keep the safety cap for future use.

- Page 36 ® Installation and Commissioning R&S TS7124AS Connecting to Control and Power Use a straight-through cable for the RS-232 connection to the control computer Two types of devices compatible with RS-232 interfaces must be distinguished: ● A "DTE" is a Data Terminal Equipment, for example a built-in serial port in a PC ●...

-

Page 37: Testing Safety Systems

® Installation and Commissioning R&S TS7124AS Testing Safety Systems To activate the chamber Connecting the chamber to power activates it. It does not have a separate [ON / OFF] switch. 1. CAUTION! Initial door movement can cause injury. When you connect the chamber to power, the door can move abruptly. -

Page 38: Defining Zones Of Restricted Access

® Installation and Commissioning R&S TS7124AS Defining Zones of Restricted Access Take these steps if the automatic emergency deactivation mechanism fails: a) Stop working with the chamber immediately. b) Take the chamber out of commission to make sure that nobody else uses it. - Page 39 ® Installation and Commissioning R&S TS7124AS Defining Zones of Restricted Access Figure 6-11: Zones of restricted access marked on the ground Door zone = Inner marking lines; here: yellow and black Work zone = Outer marking lines; here: red and black To mark the zones of restricted access 1.

-

Page 40: Adjusting The Door Speed

® Installation and Commissioning R&S TS7124AS Adjusting the Door Speed 10. If you move the chamber to a new location, mark the zones on the ground again. 6.8 Adjusting the Door Speed In the array of control connectors on the rear side of the chamber, there are two control screws for adjusting the door speed. - Page 41 ® Installation and Commissioning R&S TS7124AS Adjusting the Door Speed Otherwise, wrong timeout values can have the following consequences: ● If the timeout value is set too high (long time), it takes the door control system lon- ger than necessary to detect a blocked door.

-

Page 42: Operation

® Operation R&S TS7124AS Activating the Chamber 7 Operation Familiarize yourself with residual risks and potentially dangerous situations. Chapter 2.2, "Residual Risks", on page 10 and Chapter 2.3, "Potentially Danger- Situations", on page 11. Operating the chamber consists of the activities described in the following subchapters: ●... -

Page 43: Deactivating The Chamber

® Operation R&S TS7124AS Deactivating the Chamber Figure 7-1: Control and supply connectors on the left and right rear arrays of the chamber 1 = Grounding terminal (earth ground contact) 2 = Compressed-air supply (6 mm tube with push-pull adapter), connected to quick coupling plug KS3-1/8-A... -

Page 44: Operating The Door

® Operation R&S TS7124AS Operating the Door 7.3 Operating the Door This chapter describes manual control of the door by pushing the Push-Button Switch Unit. For remotely controlled door operation, refer to Chapter 8.3, "Door Operation Com- mands", on page 51. If the software of a test system sends the door control com- mands, also DUT handling can be automated by a system that replaces the tasks of a human operator. - Page 45 ® Operation R&S TS7124AS Operating the Door To control opening and closing of the door manually, you can use the Push-Button Switch Unit. Also, you can manually push the open door to let it close, see "Push door to close it"...

-

Page 46: Placing A Dut In The Chamber

® Operation R&S TS7124AS Connecting a DUT 7.4 Placing a DUT in the Chamber Familiarize yourself with residual risks and potentially dangerous situations. "Moving door" on page 11 and "Operating the door" on page 13. Placing options You can place your DUT on a tray that is mounted at the door in an upper or lower position. -

Page 47: Preparing For Shift End

® Operation R&S TS7124AS Preparing for Shift End These feedthroughs have interior and exterior connectors. ● Every user can connect a DUT to interior feedthrough connectors in the door, hence connectors that face the chamber's inside. ● Only an expert user is allowed to do the following: –... -

Page 48: Remote Control Commands

® Remote Control Commands R&S TS7124AS 8 Remote Control Commands Every user except the operator is allowed to use all remote control commands. As an operator, you are allowed to use only the remote control commands in Chap- ter 8.3, "Door Operation Commands",... -

Page 49: Common Commands

® Remote Control Commands R&S TS7124AS Common Commands The RC module uses the following termination character: ● You can send commands with either \n ("new line", LF, ASCII character 10) or \r ("carriage return", CR, ASCII character 13), but not in combination (\r\n) ●... -

Page 50: Remote Configuration Commands

Example: Reply: AM=DHCP:HOSTNAME=TS7124AS:IP=192.168.78.4: NETMASK=255.255.255.0:GATEWAY=192.168.78.1 In this example, the address model (AM) is DHCP, hence not STATIC, see NET:DHCP. The hostname is TS7124AS. The IP address 192.168.78.4 The netmask is 255.255.255.0 The gateway is 192.168.78.1 Usage: Query only If the address model (AM) is STATIC, the hostname part of the reply string is omitted. -

Page 51: Door Operation Commands

If you use the command without entering any characters for the hostname, the RC module returns "ERR". Parameters: <hostname> We recommend using a combination of the string "TS7124AS-" and the six-digit serial number of the chamber. For example, "TS7124AS-100123". Usage: Setting only 8.3 Door Operation Commands... - Page 52 ® Remote Control Commands R&S TS7124AS Door Operation Commands DOOR? Queries the chamber's door status. Example: DOOR? Possible replies: OPEN: the door has already opened completely. CLOSED: the door has already closed completely. PENDING: the door is currently opening or closing, transmitted...

-

Page 53: List Of Commands

® Remote Control Commands R&S TS7124AS List of Commands The expected time is defined by the command. TIMEOUT To query the state at any time, use the command. DOOR? Usage: Event TIMEOUT:<seconds> Sets the timeout value for a door status error. - Page 54 ® Remote Control Commands R&S TS7124AS List of Commands DOOR_TOUCH_CLOSE:<boolean>....................... 53 DOOR?................................52 MODEL?................................49 NET:<IP>:<NETMASK>:<GATEWAY>......................51 NET:DHCP...............................50 NET:HN:<hostname>............................51 NET?................................50 OPEN................................52 TIMEOUT:<seconds>............................53 Instructions Handbook 1179.2948.02 ─ 01...

-

Page 55: Inspection And Maintenance

® Inspection and Maintenance R&S TS7124AS Regular Safety Inspections 9 Inspection and Maintenance Familiarize yourself with residual risks and potentially dangerous situations. Chapter 2.2, "Residual Risks", on page 10 and Chapter 2.3, "Potentially Danger- Situations", on page 11. The chamber has no factory default settings, except the door speed, see page ●... -

Page 56: Preparing The Chamber For Maintenance

® Inspection and Maintenance R&S TS7124AS Performing Maintenance Tasks Due to normal wear, the performance of any system can degrade over time. This per- formance degradation can also impair system safety. To prevent any risks, we recom- mend a regular safety and performance check of the chamber once a year. -

Page 57: Checking The Absorber

® Inspection and Maintenance R&S TS7124AS Performing Maintenance Tasks 2. If pressure tubes or couplings are defective, replace these parts. To check the test equipment This check is restricted to the maintenance personnel. 1. Check the antennas, cables and connectors by coupling measurements from one antenna towards the others. -

Page 58: Cleaning The Gasket

® Inspection and Maintenance R&S TS7124AS Performing Maintenance Tasks 3. Clean the interior of the chamber with a vacuum cleaner. Run the vacuum cleaner on a low power setting and move its nozzle carefully, to avoid damaging the absorber material in the chamber. -

Page 59: Troubleshooting And Repair

® Troubleshooting and Repair R&S TS7124AS Controller Conflicts 10 Troubleshooting and Repair Every user except the operator is allowed to perform the activities described in this chapter. Any repair activities are allowed for Rohde & Schwarz service personnel only. For shipment, see Chapter 5, "Transportation, Handling and... - Page 60 ® Troubleshooting and Repair R&S TS7124AS Controller Conflicts You can address the IRC remotely via one of the following paths: ● "SER": Computer via RS-232 serial interface ● "LAN": Computer via Ethernet (LAN cable) If you use a combination of these control devices and paths, some of the following operating modes can result in special cases: ●...

-

Page 61: Contacting Customer Support

® Troubleshooting and Repair R&S TS7124AS Contacting Customer Support Figure 10-1: IRC module inside the chamber (cover removed) 1 = Internal remote control (IRC) module 2 = Right array of supply and control connectors on the rear side of the chamber 10.3 Contacting Customer Support... -

Page 62: Disabling And Scrapping

® Disabling and Scrapping R&S TS7124AS Taking Out of Commission 11 Disabling and Scrapping Every user except the operator is allowed to perform the activities described in this chapter. Familiarize yourself with residual risks and potentially dangerous situations. Chapter 2.2, "Residual Risks",... - Page 63 ® Disabling and Scrapping R&S TS7124AS Taking Out of Commission 3. Store the power supply unit for later use. 4. Disconnect all control connections from the chamber. 5. If you disconnect the Push-Button Switch Unit from the 25-pin D-Sub connector...

-

Page 64: Dismounting

® Disabling and Scrapping R&S TS7124AS Dismounting 3. While keeping the blue ring pushed in, gently pull the tube out of the adapter in the opposite direction, as indicated by the black arrow. 4. If you wish to keep the push-pull adapter with the chamber, place it back on the quick-coupling plug: a) Hold the adapter at its rear part. -

Page 65: Disposal

® Disabling and Scrapping R&S TS7124AS Disposal 4. If you wish to transport the chamber to a different place or into storage, see Chap- ter 5, "Transportation, Handling and Storage", on page 21. 11.3 Disposal Rohde & Schwarz is committed to making careful, ecologically sound use of natural resources and minimizing the environmental footprint of our products. -

Page 66: Glossary: List Of Frequently Used Terms And Abbreviations

Person with technical skills and profound experience in cali- brating electronic and systems. See also roles. chamber: The R&S TS7124AS, also referred to as "the product" D-Sub: Electrical D-subminiature connector, surrounded by a D-shaped metal support DUT: Device under test... - Page 67 ® Glossary: List of Frequently Used Terms and Abbreviations R&S TS7124AS roles: The handbook defines the following roles for performing various tasks with the chamber: user operator expert user supervisor trainer transportation appointee maintenance personnel service personnel calibration appointee service personnel: Service personnel appointed or employed by Rohde & Schwarz.

-

Page 68: Index

® Index R&S TS7124AS Index Documentation overview ............. 7 Door .................. 17 Absorber check ..............57 Speed adjustment ............40 Accessories Status indication ............44 Control unit ..............20 Door error ................59 Push-button switch unit ..........20 Door operation ..............44 Rack mounting kit ............ - Page 69 ® Index R&S TS7124AS Mounting ................26 In a rack ..............28 On a table ..............27 Unpacking ................. 25 Network query ..............50 Vacuum cleaner ..............57 Version ................49 Network setting ..............51 Open door ..............44, 52 WEEE ................65 White papers ...............

Need help?

Do you have a question about the TS7124AS and is the answer not in the manual?

Questions and answers