Summary of Contents for ARCA ARCAPAQ 812-DWK Series

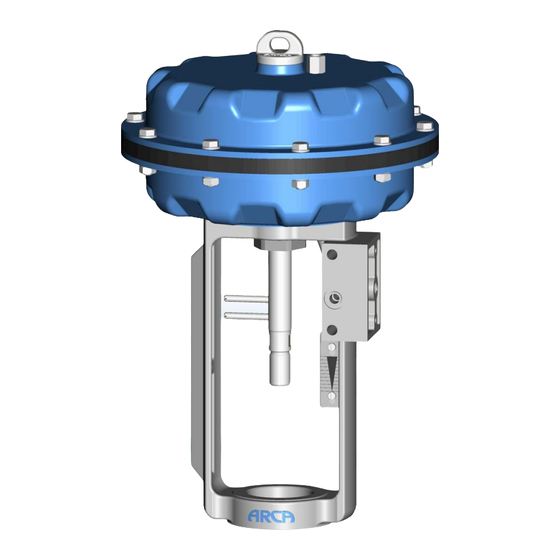

- Page 1 Operating and maintenance manual ® ARCAPAQ pneumatic piston actuator Series 812-DWK 03.2020 / 1.0...

- Page 2 Original instructions © ARCA Regler GmbH. All rights reserved. Cover picture background: Freepik.com...

-

Page 3: Table Of Contents

Validity of the manual ...................... 5 Contact details......................... 5 Other applicable documents.................... 5 Place of storage of the manual.................... 5 ARCA ONSITE ........................ 5 Safety............................ 7 General safety information ...................... 7 Explanation of symbols and notices .................. 7 Structure of the warning notices.................... 7 Intended use.......................... - Page 4 Table of contents ARCA Regler GmbH 11.2 Guide and sealing element.................... 27 11.3 Piston ............................ 27 11.4 Springs .......................... 28 Torque tables - bolted connections................... 29 12.1 Screws according to DIN EN ISO 4017/4014, DIN 939 ............ 29 12.2 Screws according to ASME B16.5 .................. 29 12.3...

-

Page 5: General Data

ARCA ONSITE Acceptance documents (if ordered) and operating documentation for this product can be downloaded from the ARCA ONSITE portal. Two options are available here: 1. Scan the QR Code¹ on the product. Further entries are not required. - Page 6 1 General data ARCA Regler GmbH 2. Visit the website https://onsite.arca-valve.com/search and enter the ARCA order no. and ARCA serial no. The order no. and serial no. can be found in the device pass and in our order confirmation. Entry example Illustration 1: ARCA ONSITE...

-

Page 7: Safety

ARCA Regler GmbH 2 Safety Safety General safety information The operating manual contains detailed descriptions for the safe installa- tion, commissioning and maintenance of the product. ▪ Read this operating manual attentively in its entirety in order to famili- arise yourself with the product. -

Page 8: Intended Use

▪ Operate the product exclusively in accordance with this operating manual and in accordance with the specification in the order confirm- ation and the device pass. ▪ Use exclusively original ARCA spare parts for the maintenance of the product. DANGER... -

Page 9: Inappropriate Use

ARCA Regler GmbH 2 Safety ▪ You are expressly directed to observe the regulations for potentially explosive equipment where necessary. Refer also to the chapter Use in potentially explosive areas (optional). Limits of use Operate the actuator only within the following limits of use. - Page 10 2 Safety ARCA Regler GmbH WARNING Exceeding the maximum ambient or media temperature Risk of explosion due to high surface temperature! The temperature class of the product is no longer valid if the maximum permissible ambient or media temperature is exceeded! ►...

- Page 11 ARCA Regler GmbH 2 Safety WARNING Exceeding the layer thickness of the surface coating Risk of explosion due to electrostatic charging of the electrically non- conductive surface coating! ► Make sure in case of overpainting that the surface coating does not exceed a total thickness of 0.2 mm.

-

Page 12: Residual Risks

2 Safety ARCA Regler GmbH ATEX nameplate Illustration 2: ATEX nameplate 1 Manufacturer 2 Type designation 3 ATEX marking for gas atmosphere 4 ATEX marking for dust atmosphere 5 Serial no. 6 "X" marking – the actuator can be used for an ambient temperat- ure of -40 °C up to a surface temperature of +80 °C. -

Page 13: Operator's Duty Of Care

ARCA Regler GmbH 2 Safety ▪ In the case of systems with explosion protection: training or instruc- tion and authorisation to carry out work on potentially explosive sys- tems. Repair work may be carried out only by trained and qualified technical personnel. -

Page 14: Personal Protective Equipment

2 Safety ARCA Regler GmbH ▪ The operator must ensure that the product is used for its intended purpose. ▪ Before commissioning the product the operator must carry out a risk assessment and define appropriate inspection and maintenance in- tervals according to the operating conditions. -

Page 15: Transport, Storage And Packaging

ARCA Regler GmbH 3 Transport, storage and packaging Transport, storage and packaging Transport WARNING Tipping or falling load! Danger of death and danger of damage to property due to load tipping over or falling! ► Only suitable and approved means of transport and lifting equipment may be used for transporting the product. -

Page 16: Nameplate

4 Nameplate ARCA Regler GmbH Nameplate Illustration 3: Nameplate 1 App. no. / Serial no. 2 Type designation / Year of manufacture 3 Valve design 4 Nominal size 5 Nominal pressure 6 Flow coefficient, characteristic curve 7 Seat diameter 8 Valve stroke... -

Page 17: Type Key

ARCA Regler GmbH 5 Type key Type key 1. Series 2. Actuator size MFI piston area 284 cm² 3. Yoke (Ø = mounting in mm) without Ø40 Ø48 Ø56 Special version 4. Stroke 20 mm 30 mm 5. Spring set... - Page 18 5 Type key ARCA Regler GmbH Example of type designation 812-223 N-DWK-0 MFI pneumatic piston actuator ─ mounting diameter 48 mm ─ stroke 20 mm ─ diaphragm head / yoke material steel / steel ─ double-acting func- tion ─ no additional equipment.

-

Page 19: Sectional Drawings

ARCA Regler GmbH 6 Sectional drawings Sectional drawings Some versions of the actuator are illustrated below. Further versions are possible by combining the different components. Connections Z1, Z2, Z3 see [9.2] Actuation signal connection Parts list Item Name Stem * Sealing ring... -

Page 20: 812-*****-Dwk0

6 Sectional drawings ARCA Regler GmbH 812-*****-DWK0 Function: Double-acting Illustration 4: 812-*****-DWK0 20 / 32 03.2020 / 1.0 Series 812-DWK... -

Page 21: 812-*****-Dwök0

ARCA Regler GmbH 6 Sectional drawings 812-*****-DWÖK0 Function: Double-acting with safety position "closed" Illustration 5: 812-*****-DWÖK0 Series 812-DWK 03.2020 / 1.0 21 / 32... -

Page 22: Functional Description

7 Functional description ARCA Regler GmbH Functional description The series 812-DWK has been developed as a double-action, pneumatic piston actuator for linear valves. The centrally located actuator stem (1) is coupled to the actuating spindle of the valve by means of a coupling. -

Page 23: Installation

ARCA Regler GmbH 8 Installation Installation Place of installation The actuator should be easily accessible from at least one side and from above. Include a catwalk or similar in the planning in case of greater heights. An electric crane or block and tackle should be provided if necessary. -

Page 24: Commissioning

9 Commissioning ARCA Regler GmbH Commissioning Adjustment Stroke adjustment ▪ CAUTION! Shear forces must not be transmitted to the actuator stem (1) when coupling actuator and valve. ▪ CAUTION! Do not turn the actuator stem (1) in a radial direction. – The pins (2) must lie in the transverse axis of the yoke (34) as shown in the sectional drawing. -

Page 25: Positioner Installation

ARCA Regler GmbH 9 Commissioning Illustration 8: Air connections with additional equipment Z3 G ½ Standard ▪ Seal connection "Z1" on the yoke (34) with a plug. ▪ Connect the air supply pipe to the connections "Z2" on the yoke (34) and "Z3"... -

Page 26: Maintenance

10 Maintenance ARCA Regler GmbH Maintenance 10.1 Care ▪ Clean the actuator stem (1) if necessary – Clean the actuator stem (1) of adhering dirt using a soft cloth NOTICE! Never use sandpaper, since this will damage the sur- face of the stem and reduce the lifetime of the stem sealing. -

Page 27: Disassembly / Assembly Of The Actuator

ARCA Regler GmbH 11 Disassembly / assembly of the actuator Disassembly / assembly of the actuator WARNING Disregarding the safety instructions Risk of injury! ► Observe the notes in the chapter entitled [2] Safety 11.1 Procedure ▪ Disassembly in the given order. -

Page 28: Springs

11 Disassembly / assembly of the actuator ARCA Regler GmbH ▪ Loosen the screws (21) ▪ Remove the top cover (118) ▪ Remove the intermediate ring (76) ▪ Replace the sealing ring (79), guide band (78) and O-rings (69) ▪ Remove the piston (77) with the stem (1) "DWÖK"... -

Page 29: Torque Tables - Bolted Connections

ARCA Regler GmbH 12 Torque tables - bolted connections Torque tables - bolted connections 12.1 Screws according to DIN EN ISO 4017/4014, DIN 939 Thread Torque [Nm] A4-80 12.2 Screws according to ASME B16.5 Thread Torque [Nm/lbf ft] A193B8 A193B7 ¼“-UNC... -

Page 30: Fault Removal

13 Fault removal ARCA Regler GmbH Fault removal WARNING Improper troubleshooting work Risk of injury! ► For all troubleshooting work, observe the corresponding notes – in particular the safety instructions – in this operating manual or in the operating manuals for the additionally installed components. -

Page 31: Disposal And Recycling

Particular attention is to be paid to dead spaces (pressure compensation, bellows, etc.) ► Observe the legal regulations for the disposal of media that are haz- ardous to health ARCA products are modularly constructed and can be sorted by material into the following components. ▪ Electronic components ▪ Metals ▪... - Page 32 www.arca-valve.com...

Need help?

Do you have a question about the ARCAPAQ 812-DWK Series and is the answer not in the manual?

Questions and answers