Table of Contents

Advertisement

Quick Links

Fusion

Thank you for choosing a Fusion

workmanship and easy maintenance have been incorporated into the

Fusion

system. The system will provide years of trouble-free service

®

when maintained according to the manufacturer's recommendations.

Please read this manual in its entirety before using the Fusion

follow all instructions to ensure proper operation. Keep this manual for

future reference along with other important onsite documents. Should

further assistance be necessary, please contact Clarus Environmental

at 1-800-928-7867.

Warning Labels

You will find warning labels on the Fusion

alarm control panel. It is very important to follow the information on

these labels to ensure your safety. Please do not remove these labels.

SEE LIST AT RIGHT FOR WARNINGS

TABLE OF CONTENTS

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Process Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System Components and Care . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Excavation and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Aeration Chamber Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pumping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

®

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Manufacturer warrants, to the purchaser and subsequent owner during

the warranty period, every new product to be free from defects in material

and workmanship under normal use and service, when properly used and

maintained, for a period of two years from date of purchase by the end

user. No allowance will be made for shipping charges, damages, labor or

other charges that may occur due to product failure, repair or replacement.

This warranty does not apply to and there shall be no warranty for any

material or product that has been disassembled without prior approval of

Manufacturer, subjected to misuse, misapplication, neglect, alteration,

accident or act of God; that has not been installed, operated or maintained

in accordance with Manufacturer's installation instructions; that has been

exposed to outside substances including but not limited to the following:

sand, gravel, cement, mud, tar, hydrocarbons, hydrocarbon derivatives (oil,

gasoline, solvents, etc.), or other abrasive or corrosive substances, wash

towels or feminine sanitary products, etc. in all pumping applications. The

warranty set out in the paragraph above is in lieu of all other warranties

expressed or implied; and we do not authorize any representative or other

person to assume for us any other liability in connection with our products.

3649 Cane Run Road • Louisville, KY 40211-1961, USA

1-800 - 928 - 7867 • 1-502-778-2731 • Fax: 1-502-774-3624

clarusenvironmental.com

Series Treatment Systems

®

OWNER'S MANUAL

SMALL COMMERICAL MODELS ZFL1120 - ZFL2400

Series Treatment System. High quality

®

, riser lids, blower, and the

®

LIMITED WARRANTY

© Copyright 2014. All rights reserved.

1.

DO NOT attempt to service the Fusion

authorized maintenance provider for all service related issues.

2.

There are buried electrical cables and piping near and around the

Fusion

. Please consult your authorized maintenance provider to

®

, and

®

locate these utilities before excavation.

3.

DO NOT bury or cover the Fusion

This is necessary to allow access for operation and maintenance

of the unit.

4.

The Fusion

blower must be unobstructed and vented for

®

proper operation. Care must be taken that no grass clippings or

other materials accumulate on or around the blower and block

ventilation.

5.

DO NOT place heavy objects over the Fusion

equipment over the Fusion

this kind is not covered by the warranty.

6.

DO NOT plant trees within 15 feet (4.6 m) of the Fusion

Treatment System.

Fusion

Model:

®

Serial No.

Installing Contractor

Phone Number

Installation Date

Maintenance Provider's Name _____________________________

Phone Number

Contact Manufacturer at, 3649 Cane Run Road, Louisville, Kentucky 40211,

Attention: Customer Support Department to obtain any needed repair or

replacement of part(s) or additional information pertaining to our warranty.

MANUFACTURER EXPRESSLY DISCLAIMS LIABILITY FOR

SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES OR

BREACH OF EXPRESSED OR IMPLIED WARRANTY; AND ANY

IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE

AND OF MERCHANTABILITY SHALL BE LIMITED TO THE DURATION

OF THE EXPRESSED WARRANTY.

Some states do not allow limitations on the duration of an implied warranty,

so the above limitation may not apply to you. Some states do not allow

the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights and you may also have other

rights which vary from state to state.

SECTION: C3.10.141

unit yourself. Contact your

®

lids with soil or other debris.

®

®

, as damage may occur. Damage of

®

ZFL-1120

ZFL-1440

ZFL-2000

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

CL0142

1014

Supersedes

1113

or drive heavy

Series

®

ZFL-1680

ZFL-2400

Advertisement

Table of Contents

Summary of Contents for Clarus Fusion Series

-

Page 1: Table Of Contents

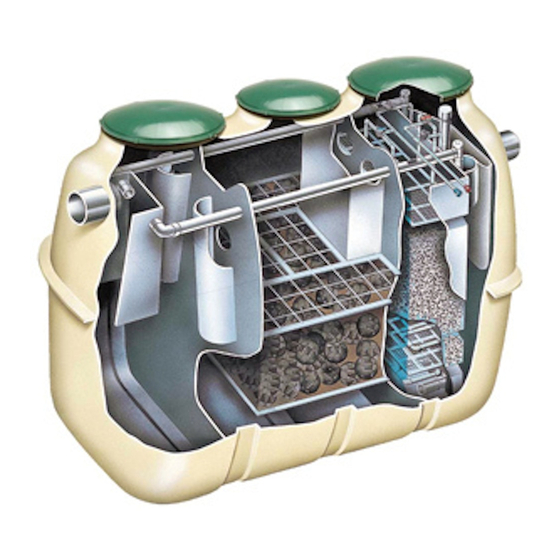

Should DO NOT bury or cover the Fusion lids with soil or other debris. ® further assistance be necessary, please contact Clarus Environmental This is necessary to allow access for operation and maintenance at 1-800-928-7867. of the unit. - Page 2 HOW A FUSION SERIES TREATMENT SYSTEM WORKS ® The Fusion is simple in design, yet advanced in its wastewater wastewater enters the Fusion , it is broken down and becomes food for ® ® treatment ability. The design has been refined over many years of biological organisms operating within the unit.

-

Page 3: Process Description

PROCESS DESCRIPTION Sedimentation Chamber Aerobic Contact Filtration Chamber This chamber is designed to physically separate solids from the The upper section is filled with board contact media and the incoming water. Scum is the floating material and sludge is the lower section is filled with hollow, mesh, cylidrical filter media. - Page 4 SYSTEM CARE The Fusion system is designed to continuously operate automatically with little direct maintenance from the owner. Periodically, a check of the ® blower area is recommended to ensure no debris obstructs the ventilation or intake areas of the blower. Also, periodically test the control panel as outlined under the alarm panel section.

- Page 5 If the maintenance provider does not correct the harmful to the Fusion treatment system. If you have any questions ® deficiencies or the service calls are not completed, please contact Clarus concerning the use of any of these substances, please contact your Environmental at 1-800-928-7867. Fusion maintenance provider.

-

Page 6: Excavation And Installation

EXCAVATION AND INSTALLATION Excavate an area large enough for the Fusion Series unit to be installed. See Figure 6 and Table 2 for the actual dimensions of the unit. ® Excavation dimensions are calculated by adding 12-18" (305-457 mm) to the length and width of the Fusion . - Page 7 Figure 7 BACKFILL THIS AREA WITH GRAVEL TO UNDER THE AIRLINE. THIS WILL HELP PREVENT SETTLING WHICH COULD CAUSE THE AIRLINE TO BREAK. AIRLINE EARTH BACKFILL GRAVEL BACKFILL GRAVEL PAD GRAVEL PAD SK3002 Table 2 Fusion DIMENSIONAL DATA RISERS ® SYSTEM Dry Weight 18"...

- Page 8 Figure 8 - Positioning Figure 9 CONCRETE ANCHOR LESS THAN 60° COLLAR 60° 4-POINT LIFTING LIFTING HOOK LIFTING LEVEL ACROSS TOP OF UNIT SK2931 LEVELING RISER/CONVERSION KIT INSTALLATION All large Fusion units are shipped without PLACE A BEAD OF risers attached due to size restraints, SILICON ON BACK OF ADAPTER BEFORE therefore all units will need to have the...

-

Page 9: Blower

TO PANEL ADAPTER WARNING ELECTRICAL SHOCK HAZARD CONDUIT TO PANEL SEAL AFTER LINE SPRING INSTALLATION CLAMPS CLARUS FUSION ® ALARM PANEL RUBBER MACHINED PIPE FOR AIR LINE ELBOW AIR HOOK UP TO PANEL AIR LINE TO FUSION ® DECORATIVE ROCK CONFIGURATION... -

Page 10: Start Up

PIPING INSTALLATION START UP Connect house sewer pipe or septic tank outlet, if required, to An installation and start-up check list is furnished the unit inlet. Make certain only household waste enters the with the information package in the blower box. Please use this as a unit (no foundation drains, gutter drains, floor drains, etc.). - Page 11 RECIRCULATION FLOW ADJUSTMENT • If the recirculation flow rate is excessively higher compared The recirculation flow is designed to be 2-4 times that of the with the value measured at the last inspection, this may indicate average design inflow. Table 5 indicates starting flow rates for that supplying pipe could be clogged.

- Page 12 AEROBIC CONTACT FILTRATION CHAMBER CLEANING Aeration The aerobic system must be flushed every maintenance visit. There are two flushing methods: (A) Air flushing and (B) Water flushing. Air flushing must be done every maintenance visit. Water flushing may be done if there is a sign of clogging in the Aerobic Contact Filtration Chamber (e.g.

-

Page 13: Operation And Maintenance

SETTLING CHAMBER ANAEROBIC CHAMBER AEROBIC CHAMBER INLET OUTLET 2" DIAMETER BACKWASH PIPE 1/2" AIRLINE ADAPTER SK2850a Figure 19 - Inspection details FUSION OPERATION AND MAINTENANCE ® The following steps are to be completed during each inspection. REQUIRED WATER QUALITY ANALYSES All information collected during the inspection is to be recorded on the Maintenance and Service Report CL0160. -

Page 14: Aeration Chamber Cleaning

FUSION OPERATION AND MAINTENANCE, continued ® OPTIONAL WATER QUALITY ANALYSES Scum – Very small amounts of scum may accumulate in the corners on the outlet end of the system. This is normal. Scum, should not be present elsewhere in the clean water storage chamber unless the recirculation rate is too high or PART D: Clean Water Storage Chamber –... -

Page 15: Fusion ® Pumping

FUSION PUMPING ® Wastewater entering the Fusion contains organic and inorganic materials. If organic in nature, it is treated and decomposed by microorganisms ® during the treatment process. If inorganic in nature, it will be stored within the Fusion . The stored materials accumulate as scum (floating) or ®... -

Page 16: Troubleshooting

ALARM PANEL & BLOWER INSPECTION AND MAINTENANCE Inspect the alarm panel for signs of water or odors inside. Toggle the Inspect the filter once the power has been disconnected by test switch on the side of the box to check that both the alarm horn and removing the filter retention screw. - Page 17 Blower Inspection and Maintenance Periodic blower maintenance is required for reliable continuous operation. Any maintenance of the blower other than those described herein this manual must be performed by an authorized service provider. NOTICE: Always turn off the power and unplug from electrical terminal before any maintenance. Failure to observe this precaution can result in a serious accident.

- Page 18 Assembly Diagram for Models AL-100 ~ AL-200 Cover Bolt Filter Cover Models AL-100~120 Semi Cover Packing Air Filter Pad Protective Switch Upper Pump Housing Hex Nut Diaphragm Magnetic Rod Diaphragm Frame Models AL-150~200 Diaphragm Housing Core Frame Diaphragm Frame Diaphragm Protective Switch Hex Nut L-tube...

- Page 19 TECHNICAL SPECIFICATIONS CtuAl Alues olume liters ZFl 1120 ZFl 1440 ZFl 1680 ZFl 2000 ZFl 2400 odel umber 5250-0018 5250-0020 5250-0022 5250-0024 5250-0026 lArus 2,112.3 (558) 2,725.5 (720) 3,168.4 (837) 3,766.5 (995) 4,519.8 (1,194) edimeNtAtioN HAmber 2,104.7 (556) 2,717.9 (718) 3,176 (839) 3,758.9 (993) 4,512.2 (1,192)

- Page 20 NOTES Trusted. Tested. Tough. ™ 3649 Cane Run Road • Louisville, KY 40211-1961 • (502) 778-2731 • FAX: (502) 774-3624 clarusenvironmental.com © Copyright 2014. All rights reserved.

Need help?

Do you have a question about the Fusion Series and is the answer not in the manual?

Questions and answers