Subscribe to Our Youtube Channel

Summary of Contents for TQC Sheen SP4500

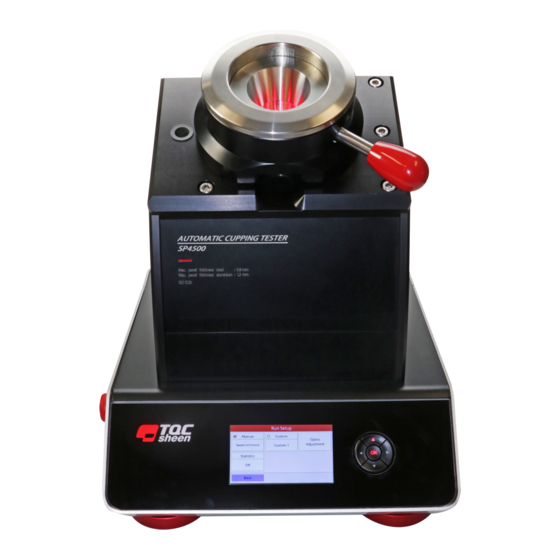

- Page 1 Automatic Cupping Tester SP4500 V1.0-1219 IMPORTANT! Before taking this instrument Operating Instructions (V1.0 1119) in use we strongly advise you to read this manual carefully.

-

Page 2: Warranty

WARRANTY TQC Sheen will grant a warranty for a period of 12 months for the Automatic Cupping Tester and 12 months for all related equipment from the date of delivery in respect of any evidence of faulty workmanship and materials. - Page 5 INDEX GENERAL MENU DISPLAY INFORMATION AND OPERATION Importance of operating manual Start screens after switch on User-responsibility Dashboard Responsibility of personnel Run Setup Dangers 8.3.1 Run Setup – Manual mode Designated purpose 8.3.2 Run Setup – Custom mode Copyright 8.3.3 Run Setup –...

- Page 7 Following these instructions is not only essential Other applications constitute improper use. TQC Sheen will not be held liable to avoid risks. It also reduces repair costs and down-time and increases the for damage resulting from improper use.

-

Page 8: Safety Instructions

• All measures involving modifications require written confirmation of approval from TQC Sheen Availability of Safety Information • Instruments which are not in fault-free condition must immediately be switched off The instruction manual should be kept at the place where the instrument •... -

Page 9: Transport And Storage

TRANSPORT AND STORAGE Packing Please take note of pictorial symbols on the packing. User: Check on Receipt Check packing for damage After unpacking check complete supply. Reporting Transport Damage and Documentation Any damage should be documented as accurately as possible (possibly photographed) and reported to the relevant insurers or, in the case of sales “delivered to customers works”, to the supplier. -

Page 10: Instrument Data

INSTRUMENT DATA Name / Article TQC Sheen Automatic Cupping Test – Microprocessor Controlled Automatic Cupping Test Scope of Supply • TQC Sheen Automatic Cupping Test • Power cord • Calibration plate • Loupe & Microscope fixture rod • Reference panel •... -

Page 11: Installation And Assembly

INSTALLATION AND ASSEMBLY Installation and Operation The instrument has to be installed in a suitable place, preferably on a sturdy table or work area, with normal ambient temperature. Special fixings are not required. Carefully unpack the apparatus and the accessories and check complete supply. - Page 12 Panel clamp with LED ring Calibration plate Brake and lock for sample holder Ethernet Emergency button USB-A Levelling supports USB-B Display with process information Machine ID-tag Panel slot TQC Sheen bus 5-key navigation switch Power entry ON/OFF Switch | 12...

- Page 13 The TQC Sheen Automatic Cupping Test is supplied with the SP4331 Cupping Test reference board. This specially designed calibration tool is stowed on the rear of the TQC Sheen Automatic Cupping Test. This precision engineered reference board allows the user to calibrate the TQC Sheen Automatic Cupping Test at custom set intervals.

- Page 14 The speed has to be entered. The TQC Sheen Automatic Cupping Test is able to operate at speeds from 0.01 mm/s up to 0.70mm/s. The speed can be set in 0.01 mm/s increments.

- Page 15 This problem is solved by setting up the Depth signal menu. The TQC Sheen Automatic Cupping Test can gives visual and audible warnings at set depth intervals. The increments of the warnings can be set with the increment op-tion.

- Page 16 8.3.3 Run Setup – Optics Adjustment The unique design of the TQC Sheen Automatic Cupping Test allows the user to use optical availa-ble loupe or USB microscope. The latter has a limited depth of focus and needs to be adjusted to zero level. In its base position the indenter is about 0.5mm below the test panel.

- Page 17 In custom mode you can also add Statistics where you just can choose Pass or Fail. If you don’t choose the fixed samples the Statistics will be shown after every single run. If you choose fixed samples the statistics will be shown after the number of samples you select to fix.

-

Page 18: Instrument Setup

8.4.1 Instrument Setup – Language The TQC Sheen Automatic Cupping Test is equipped with a multi-language menu. In this part of the menu you can select the desired language. Set the tick mark in front of the desired language. - Page 19 Instrument Setup – Power Management The display brightness is changeable here. The TQC Sheen Automatic Cupping Test contains also an Auto Power Off function where it is possi-ble to time when the device turns off automatically or turns off after a set inactive time.

- Page 20 8.4.4 Instrument Setup – Date Time The TQC Sheen Automatic Cupping Test contains a real time clock to store the time and date with each calibration. Time and date are also used for setting the calibration interval. In this menu the time and date can be set by selecting the desired figure.

- Page 21 TQC Sheen logo side. When the reference board is inserted lock it in place with the panel clamp handle. Select Start to verify that the reference board is in place.

-

Page 22: Calibration Interval

Calibration – Interval In the Calibration Setup it is possible to enter at which interval (days) the TQC Sheen Automatic Cupping Test reminds the user to carry out a calibration. The user will be reminded at the entered interval. Protect/Login The TQC Sheen Automatic Cupping Test contains a Password Protection. - Page 23 8.7.1 Run – Custom mode In the first screen the TQC Sheen Automatic Cupping Test asks the user to place the test panel and close the clamp. When done select Next to continue. 23 |...

- Page 24 The actual position of the indenter is shown. During the test “stop” can be selected to stop the test and have the indenter return to base position. It is also possible to pause /continue the indenter in Custom Run mode After the test has been completed depending on the autoreturn setting the indenter automatically returns to base position or after confirmation by pressing back.

-

Page 25: Operation

OPERATION Preparatory Work • Connect the instrument to the mains at the rear side of the housing. • When using a loupe or microscope insert the fixture rod according to illustrations. • Adjust Test cylinder such that good visibility of the test surface is guaranteed. -

Page 26: Care And Maintenance

• Generally the TQC Sheen Cupping Test does not require any main- tenance. Make sure that no paint or other liquids are spilled on the electronics or left in the holes. - Page 27 11 ANNEX A | HOW TO INSTALL LD6182 USB MICROSCOPE 27 |...

- Page 28 www.tqcsheen.com | 28...

Need help?

Do you have a question about the SP4500 and is the answer not in the manual?

Questions and answers