Table of Contents

Advertisement

Quick Links

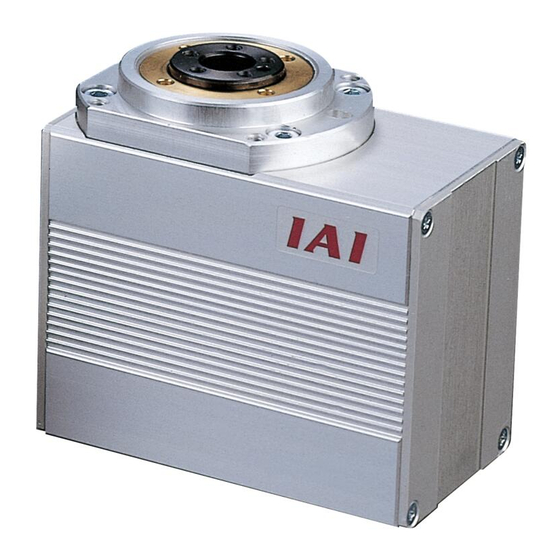

ROBO Cylinder

RCP2 Actuator

ROBO Rotary Type

Small Type, 330-degree Rotation Specification [RTBS/RTCS Types]

Small Type, Multi-rotation Specification [RTBSL/RTCSL Types]

Medium Type, 330-degree Rotation Specification [RTB/RTC Types]

Medium Type, Multi-rotation Specification [RTBL/RTCL Types]

Large Type, 330-degree Rotation Specification [RTBB/RTCB Types]

Large Type, Multi-rotation Specification [RTBBL/RTCBL Types]

Instruction Manual

Fourteenth Edition

IAI America, Inc.

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for ROBO Cylinder RCP2 Series

- Page 1 ROBO Cylinder RCP2 Actuator ROBO Rotary Type Small Type, 330-degree Rotation Specification [RTBS/RTCS Types] Small Type, Multi-rotation Specification [RTBSL/RTCSL Types] Medium Type, 330-degree Rotation Specification [RTB/RTC Types] Medium Type, Multi-rotation Specification [RTBL/RTCL Types] Large Type, 330-degree Rotation Specification [RTBB/RTCB Types]...

- Page 3 Please Read Before Use Thank you for purchasing our product. This Instruction Manual explains the handling methods, structure and maintenance of this product, among others, providing the information you need to know to use the product safely. Before using the product, be sure to read this manual and fully understand the contents explained herein to ensure safe use of the product.

-

Page 5: Table Of Contents

Table of Contents Safety Guide............................1 Caution in Handling ..........................8 International Standards Compliances....................10 Names of the Parts..........................11 Specification Check .......................12 1.1 Checking the Product........................ 12 1.1.1 Parts..........................12 1.1.2 Related Operation Manuals for the Each Controller Supported by this Product .... 12 1.1.3 How to Read the Model Nameplate................ - Page 6 External Dimensions......................65 5.1 Small Type..........................65 5.1.1 Standard Specification ....................65 5.1.2 Dustproof/Splash proof • Cleanroom Specification............67 5.2 Medium Type..........................69 5.2.1 Standard Specification ....................69 5.2.2 Dustproof/Splash Proof • Cleanroom Specification ............73 5.3 Large Type ..........................77 5.3.1 Standard Specification ....................

-

Page 7: Safety Guide

Safety Guide “Safety Guide” has been written to use the machine safely and so prevent personal injury or property damage beforehand. Make sure to read it before the operation of this product. Safety Precautions for Our Products The common safety precautions for the use of any of our robots in each operation. Operation Description Description... - Page 8 Operation Description Description Transportation ● When carrying a heavy object, do the work with two or more persons or utilize equipment such as crane. ● When the work is carried out with 2 or more persons, make it clear who is to be the leader and who to be the follower(s) and communicate well with each other to ensure the safety of the workers.

- Page 9 Operation Description Description Installation (2) Cable Wiring and Start ● Use our company’s genuine cables for connecting between the actuator and controller, and for the teaching tool. ● Do not scratch on the cable. Do not bend it forcibly. Do not pull it. Do not coil it around.

- Page 10 Operation Description Description Installation (4) Safety Measures and Start ● When the work is carried out with 2 or more persons, make it clear who is to be the leader and who to be the follower(s) and communicate well with each other to ensure the safety of the workers. ●...

- Page 11 Operation Description Description Trial ● When the work is carried out with 2 or more persons, make it clear who Operation is to be the leader and who to be the follower(s) and communicate well with each other to ensure the safety of the workers. ●...

- Page 12 Operation Description Description Maintenance ● When the work is carried out with 2 or more persons, make it clear who is to be the leader and who to be the follower(s) and communicate well Inspection with each other to ensure the safety of the workers. ●...

- Page 13 Alert Indication The safety precautions are divided into “Danger”, “Warning”, “Caution” and “Notice” according to the warning level, as follows, and described in the Instruction Manual for each model. Level Degree of Danger and Damage Symbol This indicates an imminently hazardous situation which, if the Danger Danger product is not handled correctly, will result in death or serious...

-

Page 14: Caution In Handling

Caution in Handling Make sure to follow the usage condition, environment and specification range of the product. Do not conduct any treatment or operation that is not stated in this instruction manual. Make sure to attach the actuator properly by following this operation manual. Using the product with the actuator not being certainly retained or affixed may cause abnormal noise, vibration, malfunction or shorten the product life. - Page 15 10. Dustproof/Splash proof applies non-contact labyrinth sealing structure and air purging structure. This structure shuts out foreign object and liquid from getting into output shaft by the combination of labyrinth seal and air purge. (It blocks foreign objects and liquid with air flow from the gap on the tip of the output shaft) (1) Splash proof Performance The product possesses IP*4 splash proof performance.

-

Page 16: International Standards Compliances

International Standards Compliances This actuator complies with the following overseas standard. Refer to Overseas Standard Compliance Manual (ME0287) for more detailed information. RoHS Directive CE Marking... -

Page 17: Names Of The Parts

Names of the Parts In this manual, the right and left sides of the actuator are expressed in the way it is placed horizontally as shown in the figure below, and is looked at from the motor side. • Vertical Type Output shaft Flange Front cover... -

Page 18: Specification Check

1. Specification Check 1.1 Checking the Product The standard configuration of this product is comprised of the following parts. See the component list for the details of the enclosed components. If you find any fault or missing parts, contact your local IAI distributor. 1.1.1 Parts Name... -

Page 19: How To Read The Model Nameplate

1.1.3 How to Read the Model Nameplate Model Serial number 1.1.4 How to Read the Model Number RCP2 – RTBS - I - 20P - 30 - 330 - P1 - S – NM - * Identification for IAI (Note1) use only <Options>... -

Page 20: Specifications

1.2 Specifications 1.2.1 Small Type Model RTBS / RTBSL RTCS / RTCSL Deceleration Ratio 1/30 1/45 1/30 1/45 Standard : 330 deg / Specification Operation Range : ±9999 deg Multi-rotation Specification Maximum torque 0.24 0.36 0.24 0.36 Maximum speed deg /sec Positioning ±0.05 Repeatability... - Page 21 • Allowable Moment of Inertia The maximum inertial moment of the work that can be carried in rotating motion using the actuator will vary depending on the rotational speed. Design the work after checking the operating condition and inertial moment. 330-degree rotation specification RTBS/ RTCS (deceleration ratio: 1/30) Multi-rotation specification RTBSL/RTCSL (deceleration ratio: 1/30)

- Page 22 Allowable load moment/thrust force • Check if the load moment and thrust force received by the rotational axis are within the allowable ranges specified below. Model Allowable load moment Allowable thrust force 330-degree rotation specification RTBS/RTCS 3.6 N • m 30 N Multi-rotation specification RTBSL/RTCSL...

-

Page 23: Medium Type

1.2.2 Medium Type Model RTB / RTBL RTC / RTCL Deceleration Ratio 1/20 1/30 1/20 1/30 Standard : 330 deg / Specification Operation Range Multi-rotation Specification : ±9999 deg Maximum torque N・m Maximum speed deg /sec Positioning ±0.01 Repeatability Backlash ±0.1 Allowable Moment of Kg・m... - Page 24 • Allowable Moment of Inertia The maximum inertial moment of the work that can be carried in rotating motion using the actuator will vary depending on the rotational speed. Design the work after checking the operating condition and inertial moment. 330-degree rotation specification RTB/ RTC (deceleration ratio: 1/20) Multi-rotation specification RTBL /RTCL (deceleration ratio: 1/20) Rotational speed (deg/sec)

- Page 25 Allowable load moment/thrust force • Check if the load moment and thrust force received by the rotational axis are within the allowable ranges specified below. Model Allowable load moment Allowable thrust force 330-degree rotation specification RTB/RTC 3.9 N • m 50 N Multi-rotation specification RTBL/RTCL...

-

Page 26: Large Type

1.2.3 Large Type Model RTBB / RTBBL RTCB / RTCBL Deceleration Ratio 1/20 1/30 1/20 1/30 Standard : 330 deg / Specification Operation Range Multi-rotation Specification : ±9999 deg Maximum torque N・m Maximum speed deg /sec Positioning ±0.01 Repeatability Backlash ±0.1 Allowable Moment of Kg・m... - Page 27 • Allowable Moment of Inertia The maximum inertial moment of the work that can be carried in rotating motion using the actuator will vary depending on the rotational speed. Design the work after checking the operating condition and inertial moment. 330-degree rotation specification RTBB/ RTCB (deceleration ratio: 1/20) Multi-rotation specification RTBBL/RTCBL (deceleration ratio: 1/20) Rotational speed (deg/sec)

- Page 28 Allowable load moment/thrust force • Check if the load moment and thrust force received by the rotational axis are within the allowable ranges specified below. Model Allowable load moment Allowable thrust force 330-degree rotation specification RTBB/RTCB 17.7 N • m 200 N Multi-rotation specification RTBBL/RTCBL...

-

Page 29: Cleanroom Specification

1.2.4 Cleanroom Specification Cleanliness Class 10 (0.1μm) Pipe joint for Quick joint Applicable Tube O. D. = φ6 vacuuming Vacuuming flow RTBS/RTBSL/RTCS/RTCSL RTB/RTBL/RTC/RTCL RTBB/RTBBL/RTCB/RTCBL volume 10 Nl/min 15 Nl/min 20 Nl/min 1.2.5 Dustproof/Splash Proof Specification Protection Class IP54 or equiv. Pipe joint for air Quick joint Applicable Tube O. -

Page 30: Notes On Use

1.3 Notes on Use 1.3.1 Range of Operation and Home Return ● Range of operation (position setting) The angle of movement from the home position determines the position value. • 330-degree rotation specification: Position specification range = 0 to 330 degrees •... -

Page 31: Home Return Operation

1.3.3 Home return operation • 330-degree rotation specification [1] Start of home return → [2] Detection of a mechanical stopper → [3] Reversing → [4] Movement by a specified offset → [5] Home position Range of operation (330 ) Home return Home (end of forward rotation) Movement by a... - Page 32 • Multi-rotation specification PCON controller V 0018 or earlier PSEL controller V 0.21 or earlier [1] Start of home return → [2] Home-sensor detection (when the contact B logic is selected: detection of the falling edge or ON state of the signal) → [3] Reversing → [4] Home-sensor detection (when the contact B logic is selected: detection of the rising edge or OFF state of the signal) →...

- Page 33 • Multi-rotation specification PCON controller V 0019 or later PSEL controller V 0.22 or later [Detection of home-sensor detection range (home side)] Start of home return (Search for the home-sensor detection range) Detection of a home-sensor detection range (home side) (when the contact B logic is selected: detection of the falling edge or OFF state of the signal) Reversing (Search the home-sensor non-detection range) Detection of a home-sensor non-detection range (home side) (when the contact B logic is...

-

Page 34: Options

1.4 Options 1.4.1 Reversed-home Specification (Model : NM) 1.4.2 Shaft Adapters (Model : SA) These shaft-shaped adapters are used to install a jig, etc., to the rotating part. Drawing based on combination of Drawing based on combination of Drawing based on combination of RCP2-RTB/RTBL RCP2-RTBB/RTBBL RCP2-RTBS/RTBSL... - Page 35 1.4.3 Table Adapters (Model : TA) These table-shaped adapters are used to install a jig, etc., to the rotating part. Drawing based on combination of Drawing based on combination of Drawing based on combination of RCP2-RTBS/RTBSL RCP2-RTB/RTBL RCP2-RTBB/RTBBL Unit model: RCP2-TA-RTB Unit model: RCP2-TA-RT Unit model: RCP2-TA-RTS (Unit weight: 0.06 kg)

-

Page 36: Brake-Equipped Type (Model: B)

RTBS/RTBSL/RTCS/RTCSL table RTB/RTBL/RTCS/RTCL table 6, counterbore depth 3.3 (5 holes are equally distributed) 8-M4 through Design surface 6.2, counterbore depth 3.3 through Design surface RTBB/RTBBL/RTCB/RTCBL table Design surface 7.5, counterbore depth 4.5 B-B section 1.4.4 Brake-Equipped Type (Model: B) -

Page 37: Motor • Encoder Cables

Motor • Encoder Cables 1.5.1 Small Type [RTBS, RTBSL, RTCS, RTCSL] [PMEC, PSEP, MSEP, MSEL, PCON-CA controller] 1) Motor • Encoder Integrated Cables : CB-RPSEP-MPA□□□ (18) (10) (45) (Front view) Minimum Bending R r = 68 or more (Movable Use) Mechanical side Controller side r = 34 or more (Fixed) - Page 38 [PCON-CY/SE/PL/PO, PSEL controller] 2) Motor • Encoder Integrated Cables : CB-PCS-MPA□□□ (18) (20) (23) (Front view) Minimum Bending R r = 68 or more (Movable Use) (Front view) r = 34 or more (Fixed) Controller side Mechanical side (Note) The bending radius is that after the cables have changed. The value before changing is different.

-

Page 39: Medium Type (Rtb, Rtbl, Rtc, Rtcl) Large Type (Rtbb, Rtbbl, Rtcb, Rtcbl)

1.5.2 Medium Type (RTB, RTBL, RTC, RTCL) Large Type (RTBB, RTBBL, RTCB, RTCBL) [PMEC, PSEP, MSEP, MSEL, PCON-CA controller] 1) Motor • Encoder Integrated Cables : CB-PSEP-MPA□□□ (20) (15) (10) (15) (14) (Front view) Mechanical side Controller side Minimum Bending R r = 68 or more (Movable Use) Mechanical side Controller side Terminal No. - Page 40 [PCON-CY / SE / PL / PO, PSEL controller] 2) Motor Cable : CB-RCP2-MA□□□ (20) (20) (14) (Front view) (Front view) Machanical side Controller side M cable Orange Yellow Gray Gray I-1318119-3 Orange SLP-06V White ( AMP ) ( JST ) Yellow Orange (black 1) Pink...

-

Page 41: Cleanroom, Dust And Splash-Proof Type

1.5.3 Cleanroom, Dust and Splash-Proof Type [PMEC, PSEP, MSEP, MSEL, PCON-CA controller] 1) Motor • Encoder Integrated Cables : CB-CAN-MPA□□□ (15) (50) (50) (30) Actuator side Controller side Connector: DF62B-24S-2.2C Connector: PADP-24V-1-S Contact: DF62-2428SCFA (For AWG26) Contact: DF62-22SCFA (For AWG22) SPND-002T-C0.5 (For AWG26) SPND-001T-C0.5 (For AWG22) Connection diagram... - Page 42 2) Motor • Encoder Integrated Robot Cables : CB-CAN-MPA□□□-RB (15) (50) (50) (30) Actuator side Controller side Connector: DF62B-24S-2.2C Connector: PADP-24V-1-S Contact: DF62-2428SCFA (For AWG26) Contact: DF62-22SCFA (For AWG22) SPND-002T-C0.5 (For AWG26) SPND-001T-C0.5 (For AWG22) Connection diagram Actuator side Controller side Electric Wire Electric Wire Thickness...

- Page 43 [PCON-CY / SE / PL / PO, PSEL controller] 3) Motor • Encoder Integrated Robot Cables : CB-PCS2-MPA□□□ (150) 100±20 (50) (15) (40) (20) Connector: 1-1318119-3(AMP) Contact: 1318107-1(AMP) (20) Connector: DF62C-24S-2.2C(10) (Manufacturer: Hirose) Contact: DF62-2428SCFA (Manufacturer: Hirose) DF62-22SCFA (Manufacturer: Hirose) Connector: PHDR-16VS(JST) Contact:...

-

Page 44: Installation

2. Installation 2.1 Transportation [1] Handling of the Actuator Unless otherwise specified, the actuator is shipped with each axis unit packaged separately. (1) Handling the Packed Unit Do not damage or drop. The package is not applied with any special treatment that enables it to resist an impact caused by a drop or crash. - Page 45 Handling in the Assembled Condition This is the case when the product is delivered from our factory under a condition that it is assembled with other actuators. The combined axes are delivered in a package that the frame is nailed on the lumber base. The sliders are fixed so they would not accidently move. The actuators are also fixed so the tip of it would not shake due to the external vibration.

-

Page 46: Installation And Storage • Preservation Environment

2.2 Installation and Storage • Preservation Environment Installation Environment The actuator should be installed in a location other than those specified below. Also provide sufficient work space required for maintenance inspection. Where the actuator receives radiant heat from strong heat sources such as heat treatment furnaces Where the ambient temperature exceeds the range of 0 to 40°C Where the temperature changes rapidly and condensation occurs... -

Page 47: How To Install

2.3 How to Install This chapter explains how to install the actuator on your mechanical system. 2.3.1 Installation Orientation Follow the information below when installing the actuator, as a rule. Do pay attention to these items (except with custom-order models). : Possible ×... -

Page 48: Installation Of The Actuator

2.4 Installation of the Actuator 2.4.1 Small Type • 330-degree Rotation Specification RTBS, Multi-Rotation Specification RTBSL (Vertical Type) Flange-side mounting surface 4-M3, depth 3.5 + 0.010 φ 3H7 depth 4 4-M3, depth 7 21.8 +0.02 φ 36h7 φ 3 depth 2.5 0.025 0.007 φ... - Page 49 • 330-degree Rotation Specification RTCS, Multi-Rotation Specification RTCSL (Flat Type) 11.6 0.04 depth 2.5 21.8 4-M3 depth 7 0.02 φ 3 depth 2.5 4- M3 depth 5.5 4-M3 depth 3.5 0.010 φ 3H7 depth 4 Flange-side mounting surface Bottom mounting surface φ...

-

Page 50: Medium Type

2.4.2 Medium Type • 330-degree Rotation Specification RTB, Multi-Rotation Specification RTBL (Vertical Type) Flange-side mounting surface 5-M3 depth 6 φ 3H 7 depth 4 26.5 4-M4 depth 7 φ 45h7 +0.03 depth 2..5 φ 4 φ 24h7 φ 11H7 depth 10 depth 8 4-M 4 + 0.05... - Page 51 • 330-degree Rotation Specification RTC, Multi-Rotation Specification RTCL (Flat Type) + 0.05 depth 2.5 5-M3 depth 6 φ 3H 7 depth 4 26.5 depth 7 4-M4 4-M 4 depth 8 + 0.03 φ 4 depth 2.5 Flange-side mounting surface Bottom mounting surface φ...

-

Page 52: Large Type

2.4.3 Large Type • 330-degree Rotation Specification RTBB, Multi-Rotation Specification RTBBL (Vertical Type) + 0.012 4- M5 depth 8.6 φ 4H7 depth 5 Flange-side mounting surface depth 7 6- M4 38.5 φ 65h7 + 0.05 - 0.030 depth 3.5 φ 5 - 0.009 φ... - Page 53 • 330-degree Rotation Specification RTCB, Multi-Rotation Specification RTCBL (Flat Type) 14.5 + 0.05 depth 3.5 4- M5 depth 8.6 78.5 38.5 4- M5 depth 10 depth 7 6-M4 + 0.05 φ 5 depth 3.5 + 0.012 φ 4H7 depth 5 Bottom mounting surface Flange-side mounting surface φ...

-

Page 54: Output Shaft Adapters (Optional)

2.5 Output Shaft Adapters (Optional) The external dimensions of adapters that can be installed on the actuator’s output shaft are shown below. 2.5.1 Small Type • 330-degree Rotation Specification RTCB, Multi-Rotation Specification RTCBL (Vertical Type) Table adapter 4-M3 depth 7 6- M3 depth 7 21.8... - Page 55 • 330-degree Rotation Specification RTCS, Multi-Rotation Specification RTCSL (Flat Type) Table adapter 11.6 6-M3 depth 7 21.8 4-M3 depth 7 φ 36h7 - 0.025 Table adapter + 0.021 φ 35 φ 20H7 depth 0.5 + 0.04 depth 2.5 depth 5.5 4- M3 + 0.02 φ...

-

Page 56: Medium Type

2.5.2 Medium Type • 330-degree Rotation Specification RTB, Multi-Rotation Specification RTBL (Vertical Type) Table adapter 8-M4 depth 7.5 φ 45h7 φ 44 Table adapter φ 24H7 depth 1.5 Shaft adapter φ 10h7 Shaft adapter φ 45h7... - Page 57 • 330-degree Rotation Specification RTC, Multi-Rotation Specification RTCL (Flat Type) Table adapter 8-M4 depth 7.5 φ 45h7 Table adapter φ 44 φ 24H7 depth 1.5 φ10 through hole φ 15.4 depth 5.5 Shaft adapter Shaft adapter φ 10h7 φ 45h7...

-

Page 58: Large Type

2.5.3 Large Type • 330-degree Rotation Specification RTBB, Multi-Rotation Specification RTBBL (Vertical Type) Table adapter 4-M5 depth 8.6 8- M5 depth 9 38.5 φ 65h7 - 0.030 φ 64 Table adapter + 0.025 φ 40H7 depth 1.5 14.5 Shaft adapter 4-M5 depth 8.6 + 0.1 38.5... - Page 59 • 330-degree Rotation Specification RTCB, Multi-Rotation Specification RTCBL (Flat Type) Table adapter 14.5 8-M5 depth 9 4- M5 depth 8.6 38.5 φ 65h7 - 0.030 φ 64 + 0.025 Table adapter φ 40H7 depth 1.5 + 0.05 depth 3.5 4- M5 depth 10 78.5 + 0.05...

-

Page 60: Connecting With The Controller

3. Connecting with the Controller Use the IAI dedicated connection cable for the connection of the actuator to the controller. • If the dedicated connection cable cannot be secured, reduce the load on the cable by allowing it to deflect only by the weight of the cable or wire it in a self-standing cable hose, etc., having a large radius. - Page 61 Warning: For wiring, please follow the warnings stated below. When constructing a system as the machinery equipment, pay attention to the wiring and connection of each cable so they are conducted properly. Not following them may cause not only a malfunction such as cable breakage or connection failure, or an operation error, but also electric shock or electric leakage, or may even cause a fire.

- Page 62 • Do not let the cable bend, kink or twist. • Do not pull the cable with a strong force. • Pay attention not to concentrate the twisting force to one point on a cable. • Do not pinch, drop a heavy object onto or cut the cable. •...

- Page 63 • PIO line, communication line, power and driving lines are to be put separately from each other and do not tie them together. Arrange so that such lines are independently routed in the duct. Power line Duct I/O lines (flat cable) Follow the instructions below when using a cable track.

-

Page 64: Maintenance And Inspection

4. Maintenance and Inspection 4.1 Inspection Items and Schedule Perform maintenance and inspection at the intervals specified below. This schedule assumes that the actuator is operated eight hours a day. If the actuator is operated at a higher utilization, such as when the machine is used continuously day and night, reduce the inspection intervals accordingly. -

Page 65: Grease Supply

4.4 Grease Supply 4.4.1 Grease to Apply IAI uses the following grease in our plant. Kyodo Yushi AC-D No.2 Other companies also sell similar types of grease. For details, give the above grease name to the manufacturer you want to purchase from and ask what corresponding product they have available. Showa Shell Oil Albania Grease S2 Mobil Oil... -

Page 66: How To Apply The Grease

4.4.2 How to apply the grease 1) Remove the screws on the front cover (countersunk head screw M2.6 x 6), and take off the front cover. RTBS, RTBSL RTCS, RTCSL RTB, RTBL RTC, RTCL RTBB, RTBBL (Vertical Type) RTCB, RTCBL (Flat Type) 2) Remove the screws on the rear cover (countersunk head screw M2.6 x 6), and separate the rear cover from the actuator (do not forcibly pull the cables inside). - Page 67 3) While turning the gear, add grease from the opening in the rear until the bottom of the teeth is covered with grease. (Turn the input shaft to turn the output gear.) Once a sufficient amount of grease has been added, move the gear back and forth several times to evenly spread grease.

- Page 68 While turning the gear, add grease from the opening in the rear until the bottom of the teeth is covered with grease. (Turn the input shaft to turn the output gear.) Once a sufficient amount of grease has been added, move the gear back and forth several times to evenly spread grease.

- Page 69 While turning the gear, add grease from the opening in the rear until the bottom of the teeth is covered with grease. (Turn the input shaft to turn the output gear.) Once a sufficient amount of grease has been added, move the gear back and forth several times to evenly spread grease.

- Page 70 4) Install the front cover and rear cover and securely tighten the screws. When attaching the rear cover, exercise caution not to pinch the cables between the cover and actuator. Warning: • Never use fluorine grease. If fluorine grease is mixed with lithium grease, the lubricating function of grease will drop and the machine may suffer damage due to increased friction.

-

Page 71: External Dimensions

5. External Dimensions 5.1 Small Type 5.1.1 Standard Specification • 330-degree Rotation Specification RTBS, Multi-Rotation Specification RTBSL (Vertical Type) Mass [kg] 0.52... - Page 72 • 330-degree Rotation Specification RTCS, Multi-Rotation Specification RTCSL (Flat Type) Mass [kg] 0.48...

-

Page 73: Dustproof/Splash Proof • Cleanroom Specification

5.1.2 Dustproof/Splash proof • Cleanroom Specification • 330-degree Rotation Specification RTBS, Multi-Rotation Specification RTBSL (Vertical Type) Mass [kg]... - Page 74 • 330-degree Rotation Specification RTCS, Multi-Rotation Specification RTCSL (Flat Type) Mass [kg] 0.54...

-

Page 75: Medium Type

5.2 Medium Type 5.2.1 Standard Specification • 330-degree Rotation Specification RTB, Multi-Rotation Specification RTBL (Vertical Type) (9.8) 70.8 +0.05 depth 3 77.2 (5.5) 82.2 83.5 Mass [kg] 0.86... - Page 76 • 330-degree Rotation Specification RTC, Multi-Rotation Specification RTCL (Flat Type) +0.05 depth 3 52.2 53.7 Mass [kg] 0.92...

- Page 77 • Brake-Equipped 330deg-Rotation Specification RTB, Multi-Rotation Specification RTBL (Vertical Type) Mass [kg]...

- Page 78 • Brake-Equipped 330deg-Rotation Specification RTC, Multi-Rotation Specification RTCL (Flat Type) Mass [kg]...

-

Page 79: Dustproof/Splash Proof • Cleanroom Specification

5.2.2 Dustproof/Splash Proof • Cleanroom Specification • 330-degree Rotation Specification RTB, Multi-Rotation Specification RTBL (Vertical Type) Mass [kg] 0.96... - Page 80 • 330-degree Rotation Specification RTC, Multi-Rotation Specification RTCL (Flat Type) Mass [kg] 1.04...

- Page 81 • Brake-Equipped 330deg-Rotation Specification RTB, Multi-Rotation Specification RTBL (Vertical Type) Mass [kg]...

- Page 82 • Brake-Equipped 330deg-Rotation Specification RTC, Multi-Rotation Specification RTCL (Flat Type) Mass [kg] 1.42...

-

Page 83: Large Type

5.3 Large Type 5.3.1 Standard Specification • 330-degree Rotation Specification RTBB, Multi-Rotation Specification RTBBL (Vertical Type) Mass [kg]... - Page 84 • 330-degree Rotation Specification RTCB, Multi-Rotation Specification RTCBL (Flat Type) Mass [kg]...

- Page 85 • Brake-Equipped 330deg-Rotation Specification RTBB, Multi-Rotation Specification RTBBL (Vertical Type) Mass [kg]...

- Page 86 • Brake-Equipped 330deg-Rotation Specification RTCB, Multi-Rotation Specification RTCBL (Flat Type) Mass [kg]...

-

Page 87: Dustproof/Splash Proof • Cleanroom Specification

5.3.2 Dustproof/Splash Proof • Cleanroom Specification • 330-degree Rotation Specification RTBB, Multi-Rotation Specification RTBBL (Vertical Type) Mass [kg]... - Page 88 • 330-degree Rotation Specification RTCB, Multi-Rotation Specification RTCBL (Flat Type) Mass [kg]...

- Page 89 • Brake-Equipped 330deg-Rotation Specification RTBB, Multi-Rotation Specification RTBBL (Vertical Type) Mass [kg]...

- Page 90 • Brake-Equipped 330deg-Rotation Specification RTCB, Multi-Rotation Specification RTCBL (Flat Type) Mass [kg]...

-

Page 91: Life

6. Life The product life is set to 10,000,000 times (reference) of 360deg turns in the condition of maximum output torque, maximum acceleration and maximum deceleration. -

Page 92: Warranty

7. Warranty 7.1 Warranty Period One of the following periods, whichever is shorter: 18 months after shipment from IAI 12 months after delivery to the specified location 2,500 hours of operation 7.2 Scope of the Warranty Our products are covered by warranty when all of the following conditions are met. Faulty products covered by warranty will be replaced or repaired free of charge: (1) The breakdown or problem in question pertains to our product as delivered by us or our authorized dealer. -

Page 93: Conditions Of Conformance With Applicable Standards/Regulations, Etc., And Applications

7.5 Conditions of Conformance with Applicable Standards/Regulations, Etc., and Applications (1) If our product is combined with another product or any system, device, etc., used by the customer, the customer must first check the applicable standards, regulations and/or rules. The customer is also responsible for confirming that such combination with our product conforms to the applicable standards, etc. -

Page 94: Change History

Change History Revision Date Description of Revision April 2011 Seventh edition A page for CE Marking added March 2012 Eighth edition • P 1 to 7 Contents added and changed in Safety Guide • P 8 Caution in Handling added •... - Page 95 Revision Date Description of Revision August 2015 14B edition • P 31, 32 Contents added bending radius for fixed use. • P 32, 54 Change made to bending radius for movable use. • P 32 Change made to cable color •...

- Page 98 Manual No.: ME3626-14F (April 2017) Head Office: 577-1 Obane Shimizu-KU Shizuoka City Shizuoka 424-0103, Japan TEL +81-54-364-5105 FAX +81-54-364-2589 website: www.iai-robot.co.jp/ Technical Support available in USA, Europe and China Head Office: 2690 W. 237th Street, Torrance, CA 90505 TEL (310) 891-6015 FAX (310) 891-0815 Chicago Office: 110 East State Parkway, Schaumburg, IL 60173 TEL(847) 908-1400 FAX (847) 908-1399 Atlanta Office: 1220 Kennestone Circle, Suite 108, Marietta, GA 30066...

Need help?

Do you have a question about the RCP2 Series and is the answer not in the manual?

Questions and answers