Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for PlaneWave L-350

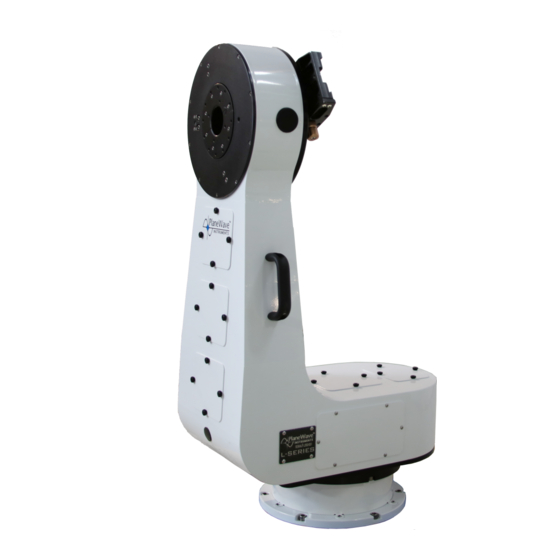

- Page 1 L-350 MECHANICAL INSTALLATION GUIDE...

-

Page 2: Table Of Contents

INSTALLING FORK-ARM MOUNTING THE SADDLE PREPARING THE OTA PREPARING SADDLE FOR OTA POSITIONING THE OTA SECURING THE OTA INSTALLING OPTIONAL 2ND SADDLE BALANCING ALTITUDE/DEC BALANCING AZIMUTH/RA POWER/COM CABLING FOR THE MOUNT CABLE ROUTING FOR ACCESSORIES & INSTRUMENTS L-350 MECHANICAL INSTALLATION GUIDE... -

Page 3: System Diagrams 1

SYSTEM DIAGRAMS 1 SIDE-VIEW (OUTSIDE OF FORK-ARM) - Page 4 SYSTEM DIAGRAMS 2 SIDE-VIEW (INSIDE OF FORK-ARM) L-350 MECHANICAL INSTALLATION GUIDE...

- Page 5 SYSTEM DIAGRAMS 3 REAR AND OVERHEAD VIEWS...

-

Page 6: Introduction

Remember all of that advice about how to properly balance by being out of balance, to keep gears engaged? None of that applies to direct-drive, and tracking is equally good on both sides of the meridian. L-350 MECHANICAL INSTALLATION GUIDE... -

Page 7: Range Of Motion

RANGE OF MOTION L-350 mounts offer +/- 350 degrees of rota- tion in the Azimuth/RA axis, measured from the “No Wrap” position. The proper “No Wrap” position is found by aligning the related marks on the drive-base section of the mount (due the +/- 350 degree motion, these marks only line up at the correct position). -

Page 8: Unpacking

60 pounds or more, if you prefer to leave the screws unit fully assembled. One person can unpack - SAE Hex-Key Set the L-350 by removing the fork-arm from the base motor and moving them separately. Opening the crate: - Begin by finding the “front” panel of the... - Page 9 Removing the fork-arm: To simplify packaging, your mount has been shipped with the drive-base and fork attached. While it is possible to lift the system in this as- sembled state with a fork-lift, crane or multi- ple people, we highly recommend that the two assemblies are separated if only one person is lifting..

- Page 10 4) Before removing any of the bolts securing the fork-arm to the base-motor: A) be sure that the Azimuth/RA locking knob is engaged, and B) it is helpful to make a reference mark for later realignment of the two assemblies. Both are shown in the top-right image.

- Page 11 8) The fork-arm is now ready to be lifted from the drive-base. With a good grip on the fork- arm’s handles, begin tipping the fork-tine to- ward you (you should still be standing on the fork-tine side of the mount), as shown to the right.

- Page 12 Dovetails / other accessories: The dovetail saddle and other accessories may be packed within boxes mounted to the floor of the crate. Be sure to open any boxes and inventory the contents. L-350 MECHANICAL INSTALLATION GUIDE...

- Page 13 Installation will be addressed below, and should be completed prior to re-assembling the mount after its unpacking. Important note on the gear-ratio of the L-350 wedge: - Altitude Adjustment is 0.55 degrees/turn - Azimuth Adjustment is 0.41 degrees/turn...

-

Page 14: Preparing For Installation

Alternatively, a crane or fork-lift may be used to lift and place the mount, depending upon accessibility of the observatory and pier to such equipment. Component weights: L-350 System: 110 LBS L-350 Fork-Arm: 70 LBS L-350 Base-Motor: 40LBS EQ Wedge (Optional): 100 LBS L-350 MECHANICAL INSTALLATION GUIDE... - Page 15 Lifting points for people: Your L-350 mount should not be lifted by one person when fully-assembled. It is reason- ably lifted by two people, if the 110LB sys- tem-weight is accabltable. Lifting the full-system: With two people lifting, each person can grip...

- Page 16 The relative lengths of these straps should be adjusted so that the mount becomes suspend- ed at an angle approximately equal to the incli- nation of the wedge’s mounting surface, sim- plifying the process of bolting the drive-base onto the wedge. L-350 MECHANICAL INSTALLATION GUIDE...

- Page 17 Hole pattern and pier-interface advice: In drawing to the right, the interface pattern is described as a 12” bolt circle, with 60-degree separation between holes. These holes should be tapped through with 3/8-16 threads. The mounting surface should be oriented so that North/South align at the midpoint between holes in the pattern, and so that there are bolt- holes directly aligning to East and West.

-

Page 18: Mounting Drive-Base To Pier

The before fully tightening any of the bolts. L-350’s NoWrap marker is a notch in the base- flange, adjacent to the Azimuth Lock (visible in the models on page 12). -

Page 19: Installing Eq Wedge

INSTALLING EQ WEDGE Leveling: Leveling of the wedge, while not critical to 4) Insert the hub through the top-plate, so that the system’s operation, needs to be reason- it extends into the base-plate, and then bolt it ably close to ensure polar-alignment can be onto the top-plate. -

Page 20: Attaching Drive-Base To Eq Wedge

5) Beginning with the pair of holes nearest the top of the wedge, begin inserting and thread- ing the bolts. To ensure that all go in easily, wait until all are engaged before fully tighten- ing them. L-350 MECHANICAL INSTALLATION GUIDE... -

Page 21: Installing Fork-Arm

INSTALLING FORK-ARM The procedure for installing the fork-arm onto the drive-base is common to both ALT/AZ and EQ configurations. This is most easily done with a second person. For Equatorial installations, please read the section on balancing, installing the fork-arm and instrumentation. -

Page 22: Mounting The Saddle

MOUNTING SADDLE Installing equipment for mounting the main optical-system: Your L-350 mount has been shipped with a dovetail saddle. Installation is done by bolting the saddle to the hole-pattern on the interior of the Altitude/DEC axis mounting assembly: 1) First, make sure Alt/Dec axis is oriented cor- rectly. -

Page 23: Preparing The Ota

PREPARING OTA If you have access to equipment (crane or fork- lift) or a sufficient number of assistants, there are advantages to pre-installing your camera and other instrumentation onto the telescope. This will increase the overall weight of the OTA, and the expense of the equipment being lifted at one time. -

Page 24: Preparing Saddle For Ota

6) Check proper orientation of the stability-bar for the EZ-Saddle (covered in it’s instruction sheet). For CDK12.5 and CDK14 systems, the recessed side should face the dovetail. L-350 MECHANICAL INSTALLATION GUIDE... -

Page 25: Positioning The Ota

The reference images to the right show a CDK17 being loaded onto a L-500, but this process is identical for the L-350. 1) Lift the OTA up and onto the saddle. This process is safest with 2 or more people. Ad-... -

Page 26: Securing The Ota

4) Double-check that the dovetail is fully seat- ed and secured in the saddle before everyone lets go. 5) You can now remove the Altitude/DEC axis locking-knob to check balance, covered in de- tail on page 28-29. L-350 MECHANICAL INSTALLATION GUIDE... -

Page 27: Installing Optional 2Nd Saddle

INSTALLING SECOND SADDLE The basic principles of attaching the secondary saddle are the same as for the primary. Both mounting surfaces of the Altitude/DEC axis feature bolt-patterns that will accomodate the Keller EZ-Saddle (for the CDK12.5, CDK14 and compatible with Losmandy D-series style dovetails, and similar from Celestron, Meade, ect.). -

Page 28: Balancing Altitude/Dec

Be sure that all planned cable-runs have been completed (for power/com to instrumentation and accessories) before determining final bal- ancing. Recommendations on cable-routing are covered later in this manual. L-350 MECHANICAL INSTALLATION GUIDE... -

Page 29: Balancing Azimuth/Ra

(to the base-motor), shown to the right. In the near future, PlaneWave will offer an optional balancing accessory system for the L-350. In the meantime, please start from the general recommendations below, add weight as needed and call our technical support staff for guidance, if needed. -

Page 30: Power/Com Cabling For The Mount

USB port on your PC or hub. If Ethernet will be used for PC/mount com- munication, instead of USB, cable-routing will proceed identically. The Ethernet socket is lo- cated on the same electronics panel as the USB socket. L-350 MECHANICAL INSTALLATION GUIDE... -

Page 31: Cable Routing For Accessories & Instruments

CABLE ROUTING FOR ACCESSORIES The L-350 offers an appreciable volume of stor- age space within the fork arms’ cavities. The re- sulting compartments offer routes back to the RA/Azimuth motor pass-through, and allow the storage of accessory power supplies, USB hubs/extenders, network switches, and other small devices. - Page 32 PLANEWAVE.COM - 1375 N. MAIN STREET, ADRIAN, MI 49221 - 310-639-1662...

Need help?

Do you have a question about the L-350 and is the answer not in the manual?

Questions and answers