Table of Contents

Advertisement

INSTALLATION INSTRUCTION

GENERAL

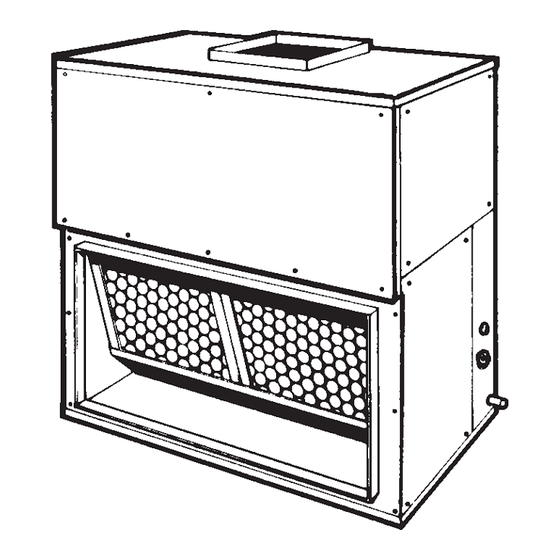

These completely assembled blower units are manufac-

tured under ISO 9002 Quality System Certification and

include a well-insulated cabinet, a DX cooling coil with

copper tubes and aluminum fins, an expansion valve, a

distributor, throwaway filters, a centrifugal blower, a

blower motor, a blower motor contactor, an adjustable

belt drive and a small holding charge of Refrigerant-22.

Blower motors and adjustable drives are factory-

installed on all units.

The units are shipped in the vertical position with a vertical air

discharge. The blower section can be repositioned as shown in

Figure1 for horizontal applications.

REFERENCE

Additional information for the accessories on this equip-

ment is available in the following instructions:

•

Electric Heater - 550.13-N10.1V

•

Supply Air Plenum - 550.13-N10.2V

•

Return Air Grille - 550.13-N10.3V

•

Base - 550.13-N10.4V

Installer should pay particular attention to the words: NOTE, CAU-

TION and WARNING. Notes are intended to clarify or make the in-

stallation easier. Cautions are given to prevent equipment damage. Warnings are given to alert installer that personal injury

®

Supersedes: Nothing

MODELS K5EU090A50A & K4EU120A50A

(WORLD 50 HZ)

SUNLINE™ SPLIT-SYSTEM

EVAPORATOR BLOWERS

(AIR COOLED)

•

Hot Water & Steam Coil - 550.13-N10.7V

Renewal Parts:

•

Refer to Parts Manual for complete listing of replacement

parts on this equipment.

All forms may be ordered from:

Publications Distribution Center

Unitary Products Group

P.O. Box 1592, York, PA 17405

INSPECTION

As soon as a unit is received, it should be inspected for

possible damage during transit. If damage is evident, the

extent of the damage should be noted on the carrier's de-

livery receipt. A separate request for inspection by the

CAUTION

THIS PRODUCT M UST BE INSTALLED IN STRICT COMPLIANCE W ITH

THE ENCLOSED INSTALLATION INSTRUCTIONS AND ANY APPLICABLE

LOCAL, STATE, AND NATIONAL CODES INCLUDING, BUT NOT LIMITED

TO, BUILDING, ELECTRICAL, AND MECHANICAL CODES.

WARNING

INCORRECT INSTALLATION MAY CREATE A CONDITION WHERE THE

OPERATION OF THE PRODUCT COULD CAUSE PERSONAL INJURY

O R P R O P E R T Y D A M A G E .

550.39-N4YI (894)

035-12122

Advertisement

Table of Contents

Summary of Contents for York SUNLINE K4EU120A50A

-

Page 1: General

OPERATION OF THE PRODUCT COULD CAUSE PERSONAL INJURY O R P R O P E R T Y D A M A G E . (AIR COOLED) 550.39-N4YI (894) Publications Distribution Center Unitary Products Group P.O. Box 1592, York, PA 17405 CAUTION WARNING 035-12122... -

Page 2: Table Of Contents

550.39-N4YI General...1 Reference ...1 Inspection ...1 Nomenclature ...2 INSTALLATION Limitations ...3 Location ...3 Clearances ...4 Rigging and Handling ...4 Vertical/horizontal Installation ...4 Duct Connections ...4 Refrigerant Mains ...5 Drain Connection...6 Supply Air Blower Adjustment ...6 Power and Control Wiring...11 MAINTENANCE Filters...12 Evaporator Coil...12 Lubrication ...12... -

Page 3: Installation

carrier's agent should be made in writing. See Local Dis- tributor for additional information. LIMITATIONS These units must be installed in accordance with applicable na- tional, local and municipal safety codes. If components are to be added to a unit to meet local codes, they are to be installed at the dealer's and/or the customer's ex- pense. -

Page 4: Clearances

550.39-N4YI CLEARANCES The clearances listed on the unit dimension drawing (Figure 9) are required for the proper service and opera- tion of the unit. RIGGING AND HANDLING Be careful when moving the unit. Do not remove any packaging until the unit is near its final location. The packaging consists of a bottom wooden skid that can be lifted with a fork truck from any direction, a card- board container that covers the entire unit, and strapping... -

Page 5: Location 3

Table 2 - PHYSICAL DATA Model Rows Deep Rows High Finned Length (in./mm) Evaporator Coil Fin/Inch Tube O.D. (in./mm) Face Area (Ft Centrifugal Blower Wheel Dia. x Width Blower Motor* Nominal Rating (HP/kW) Size Filters (4 Req'd) Face Area (Ft. Weight (Lbs,/kg) Operating Electric Heaters... -

Page 6: Clearances 4

550.39-N4YI Before brazing the refrigerant lines to these connections, remove the short panel from the unit frame and slide it (along with the grommets) onto the refrigerant lines. Af- ter the brazed joints have cooled, slide the panel back into place and secure it to the unit frame. NOTE: These units can only be piped from one side of the unit. -

Page 7: Supply Air Blower Motor Pulley Adjustment

3. Using an inclined manometer, determine the pressure drop across a dry evaporator coil. Since the moisture on an evaporator coil may vary greatly, measuring the pressure drop across a wet coil under field conditions would be inac- curate. To assure a dry coil, the refrigerant system should be de-energized while the test is being run. -

Page 8: Blower Performance

550.39-N4YI TABLE 4 - BLOWER PERFORMANCE KEU090 - SUPPLY AIR BLOWER PERFORMANCE BLOWER SPEED INPUT OUTPUT (IWG) (kW) (BHP) 2400 CFM 0.35 0.62 0.59 0.49 0.70 0.66 0.60 0.77 0.73 0.92 0.97 0.90 1.18 1.11 1.04 1.24 1.15 1.07 1000 1.58 1.35 1.26... -

Page 9: Accessory Static Resistance (Iwg/Pa)

TABLE 5 - ACCESSORY STATIC RESISTANCE (IWG) KEU090 ACCESSORY BLOWER CFM/m 10k W 16 kW Electric Heat 26 kW 36 kW Supply Air Plenum Return Air Grille Add these pressures to the ESP values in the respective blower performance table. KEU120 ACCESSORY BLOWER CFM/m... -

Page 10: Unit Dimensions And Clearances

550.39-N4YI ACCESSORIES •ELECTRIC HEATER Add 15" (381mm) to Unit Height when using 10, 16, 26 or 36kW Heater •SUPPLY AIR PLENUM Add 27" (686mm) to Unit Height when used •BASE Add 24" (610mm) to Unit Height when used MINIMUM CLEARANCES (in./mm) Side with RETURN AIR opening - 24 / 610 Side with SUPPLY AIR opening... -

Page 11: Power And Control Wiring

TABLE 7 - BLOWER MOTOR AND DRIVE DATA Adjustable Motor Pulley Blower Motor Model Range Pitch Dia (HP/kW)* (RPM) (In./mm) 3.4 - 4.4 / / 1.1 KEU090 650/850 86 - 112 3.4 - 4.4 / KEU120 2 / 1.5 700/910 86 - 112 *All motors are 1450 RPM and have a 56 frame, inherent protection and permanently lubricated ball bearings The motors have a solid base and a 1.15 serv- ice factor. -

Page 12: Drain Pan

Unitary Products Group P.O. Box 1592, York, Pennsylvania USA 17405-1592 Subject to change without notice. Printed in U.S.A Copyright © by York International Corporation 1994. All Rights Reserved. MAINTENANCE LUBRICATION — The bearings for the blower shaft and the blower motors are permanently lubricated and should not require additional lubricant.

Need help?

Do you have a question about the SUNLINE K4EU120A50A and is the answer not in the manual?

Questions and answers