Advertisement

Table of Contents

- 1 Section 1: Finding Your Model Number

- 2 Section 2: Calling Customer Support

- 3 Section 3: Important Safe Operation Practices

- 4 General Operation

- 5 Section 4: Set-Up Instructions

- 6 Tools Required for Assembly

- 7 Section 5: Controls

- 8 Section 6: Operation

- 9 Using Your Chipper-Shredder

- 10 Section 7: Maintenance

- 11 General Recommendations

- 12 Section 8: Off-Season Storage

- 13 Section 9: Trouble Shooting Guide

- Download this manual

See also:

Operator's Manual

O

PERATOR'S

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning:

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 368022 Cleveland, Ohio 44136-9722.

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

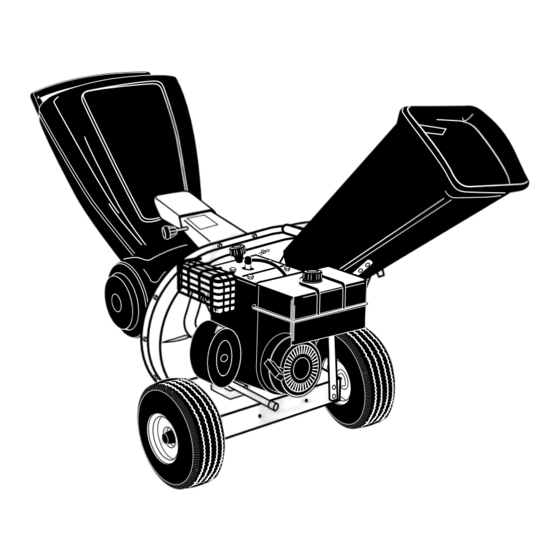

(Model 465A shown)

M

ANUAL

Chipper - Shredders

Model Series

462 thru 465

FORM NO. 770-10038A

5/99

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Yard Machines 462 Thru 465

- Page 1 Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 368022 Cleveland, Ohio 44136-9722. MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722 PRINTED IN U.S.A. ANUAL Chipper - Shredders Model Series 462 thru 465 FORM NO. 770-10038A 5/99...

-

Page 2: Section 1: Finding Your Model Number

SECTION 1: FINDING YOUR MODEL NUMBER This Operator’s Manual is an important part of your new chipper-shredder. It will help you assemble, prepare and maintain your chipper-shredder. Please read and understand what it says. Before you prepare your chipper-shredder for its first use, please locate the model plate and copy the information from it in this Operator’s Manual. -

Page 3: Section 3: Important Safe Operation Practices

SECTION 3: IMPORTANT SAFE OPERATION PRACTICES WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING TO OPERATE YOUR CHIPPER-SHREDDER. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. - Page 4 • Inspect for damage. • Repair or replace any damaged parts. • Check for any loose parts and tighten to assure continued safe operation. • Never attempt to attach or remove catcher bag when engine is running. Shut the engine off and wait for the impeller to come to a complete stop.

- Page 5 • DO NOT DEPOSIT BRANCHES LARGER THAN 1/2 INCH DIAMETER INTO THIS HOPPER. • WEAR APPROVED SAFETY GLASSES, GLOVES AND EAR PROTECTION. AVOID LOOSE FITTING CLOTHING. • Read the Owner’s Manual before starting and using this chipper/shredder. • Keep hands, feet, face and clothing out of shredder hopper inlet and chipper chute inlet. •...

-

Page 6: Section 4: Set-Up Instructions

SECTION 4: SET-UP INSTRUCTIONS IMPORTANT: After assembly, service engine with gasoline, and check oil level as instructed in the separate engine manual packed with your unit. NOTE: All references to right or left side of the snow thrower are determined from behind the unit in the operating position. - Page 7 9. Use wrenches to remove hex lock nut (D). Remove two spacers (E), and hex bolt (F) from housing assembly. assembly, do not remove the second spacer from the hex bolt. See Figure 5. 10. Place the discharge chute in position on the discharge opening.

-

Page 8: Section 5: Controls

SECTION 5: CONTROLS Release Choke Lever Throttle Control Figure 8 Release Rod: Used to release the hopper when raising or lowering. See Figure 8. Choke Lever: Used to enrich the fuel mixture in the carburetor when starting a cold engine. Starter Handle: Used to manually start the engine. -

Page 9: Using Your Chipper-Shredder

5. Pull rope with a rapid full arm stroke. Let rope return to starter slowly. 6. When engine starts, move choke lever to half choke position until engine runs smoothly and then to No Choke position. 7. If engine fails to start after three pulls, move choke lever to No Choke position and pull starter rope again. - Page 10 WARNING: Temperature of muffler and nearby areas may exceed 150 Avoid these areas. LUBRICATION Lubricate the pivot points on the release rod bracket, hopper assembly, and chute deflector once a season using a light oil. CLEANING • Clean engine periodically. Remove dirt and debris with a cloth or brush.

- Page 11 7. Reinstall the screen. 8. Put the discharge chute back to its original position and tighten the hand knobs. NOTE: Be certain to reassemble the flail screen with the curved side down. Clevis Hex Nuts Washers Chipper Chute Hairpin Clip Hand Knobs Figure 9 SHARPENING OR REPLACING THE...

-

Page 12: Section 8: Off-Season Storage

3. Remove the six hex lock nuts and flat washers from the housing weld bolts using a 1/2" wrench. Separate the chipper-shredder into two halves. 4. Remove the support plate. NOTE: When reassembling, make certain the embossed tab faces inward towards the impeller. 5. -

Page 13: Section 9: Trouble Shooting Guide

SECTION 9: TROUBLE SHOOTING GUIDE Trouble Possible Cause(s) Engine fails to start Dirty air cleaner. Choke not in ON position. Spark plug wire disconnected. Cannot pull recoil cord. Fuel tank empty, or stale fuel. Fuel shut-off valve closed (if so equipped). - Page 14 Model Series 462 thru 465 72 69 18 19...

- Page 15 Model Series 462 thru 465 REF. PART DESCRIPTION 731-1899 Chipper Chute 728-0175 Pop Rivet 735-0249 Chute Flap 781-0633 Flat Strip 710-0751 Hex Cap Screw 1/4-20 x .620 681-0068 Chipper Chute Am 736-0173 Flat Washer.28 ID x .74 OD 710-0106 Hex Cap Screw 1/4-20 x 1.25...

- Page 16 MANUFACTURER’S LIMITED WARRANTY FOR: The limited warranty set forth below is given by MTD PRODUCTS INC (“MTD”) with respect to new merchandise purchased and used in the United States, its possessions and territories. MTD warrants this product against defects in material and workmanship for a period of two (2) years commencing on the date of original purchase and will, at its option, repair or replace, free of charge, any part found to be defective in...

Need help?

Do you have a question about the 462 Thru 465 and is the answer not in the manual?

Questions and answers