Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for TOX EPW400

- Page 1 Operating Manual Pressing monitor EPW400 • Force/Distance Measurement Original operating manual Firmware Version V1.08.88 ® PRESSOTECHNIK GmbH & Co. KG Riedstraße 4 D - 88250 Weingarten Phone +49 (0) 751/5007-0 Fax +49 (0) 751/52391 www.tox-pressotechnik.com...

- Page 2 This operating manual applies to devices running firmware version V1.08.81 or higher. ® PRESSOTECHNIK GmbH & Co. KG Riedstraße 4 D - 88250 Weingarten Phone +49 (0) 751/5007-0 Fax +49 (0) 751/52391 www.tox-pressotechnik.com E-Mail: info@tox-de.com...

- Page 4 ESEIFERTH@TOX-US.COM It is the responsibility of TOX-PRESSOTECHNIK L L C, the Applicant, to inform its manufacturers of that the IPI must be successfully completed before product may be shipped with the UL Mark. Instructions for the IPI will be sent to our inspection center nearest to each of your manufacturing locations.

- Page 5 Email: Marks (as needed) may be obtained from: Information on the UL Marks, including our new Enhanced UL Certification Marks can be found on the UL website at https://markshub.ul.com Within Canada, there are federal and local statutes and regulations, such as the Consumer Packaging and Labeling Act, requiring the use of bilingual product markings on products intended for the Canadian market.

-

Page 6: Table Of Contents

3.2.8 Built-in version: pin assignment, analog signals (channel Y force / channel X distance) for analog standard signals ......28 3.2.9 Built-in version: pin assignment, analog standard signals .... 30 Overview of wall-mounted version ............32 3.3.1 Power supply ................32 3.3.2 Dimensions of wall-mounted version ..........32 OM 100.EPW400.202002.en... - Page 7 3.3.3 Wall-mounted housing: digital inputs I0-I15 (25-pin D-sub female connector) ..................33 3.3.4 Wall-mounted housing: digital outputs Q0-Q7 (25-pin D-sub female connector) ..................33 3.3.5 Standard wall-mounted housing: pin assignment, DMS force transducer (channel Y) ..............34 3.3.6 Wall-mounted housing: pin assignment, force transducer (channel Y) Only hardware model EPW 400.202.1X ........

- Page 8 6.2.29 Insert max. force at the end of the curve ........83 6.2.30 Start/stop condition ..............83 6.2.31 Distance-triggered ................ 83 6.2.32 Force-triggered ................84 6.2.33 Start/stop from PLC ..............84 6.2.34 Switching points ................84 6.2.35 Configuration I/O ................85 6.2.36 Configuring the analog outputs ............ 87 OM 100.EPW400.202002.en...

- Page 9 6.2.37 Valuation options ................. 88 6.2.38 Activate NOK buzzer (NOK buzzer) ..........88 6.2.39 NOK acknowledge external (reset) ..........88 6.2.40 NOK acknowledge via display (reset) .......... 88 6.2.41 Monitor TDC sensor ..............88 6.2.42 Apply configuration ..............89 Data ......................90 6.3.1 Curve data ...................

- Page 10 Table of contents Start/Stop ....................112 7.1.1 Changing the program number ..........113 7.1.2 Zero point adjustment ..............113 ® Software module TOX softWare ..............114 Networking via Ethernet ................ 114 Network server program EPW 400_Server ........... 114 Error messages .................... 115 10 Firmware update ..................

-

Page 11: Introduction

Introduction Introduction Explanation of symbols An arrow at the beginning of a paragraph indicates the action steps you must complete. This tick at the beginning of a paragraph indicates a condition that must be met before beginning the next step. Danger notifications: Safety Here you will find instructions for the prevention of damage. -

Page 12: Brief Description

EPW 400 are changed, e.g. during a program change or zero point adjustment, or if the settings are being changed via the keyboard, it is not possible to begin a measuring cycle. The readiness for measuring is shown on the display by means of ready signal 'RDY'. OM 100.EPW400.202002.en... -

Page 13: Version .22

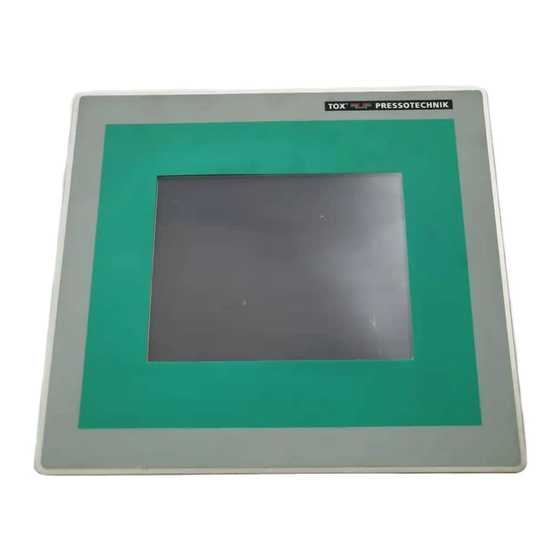

Brief description Version .22 Principle display of the Pressing Monitor EPW400 as Version 22, with changeover from channel pair A to channel pair B. You have the option of setting channels A and B for each process independent of force and distance. -

Page 14: Technical Data

1 x keyboard interface for max. 64 buttons with Buffer battery Lithium cell, pluggable Battery type Li 3 V / 950 mAh CR2477N Buffer time at 20°C typically 5 years Battery monitoring typically 2.65 V Buffer time for battery change min. 10 minutes Order number: 300215 OM 100.EPW400.202002.en... -

Page 15: Connections

Technical data Battery change Recommendation: change battery after 2 years. To avoid data loss while performing the battery change, turn the de- vice on for at least 10 minutes before the change-over. Disconnect the power supply Discharge any electrostatic charges Remove the cover from the lithium battery Remove the battery. -

Page 16: Digital Inputs

On devices with field bus interface, the outputs, such as "Ready for operation", are written on both the digital outputs and the field bus outputs. Whether the inputs are read on the digital inputs or on the field bus inputs is determined in menu 'Additional- >Communication parameters->Anybus-S Subprint'. OM 100.EPW400.202002.en... -

Page 17: Usb

Technical data 3.1.6 Number of 2 x host (full-speed) channels 1 x device (high-speed) USB 2.0 According to USB device specification, USB 2.0 compatible, type A and B Connection to high-powered hub/host Max. cable length 5 m + 5 V Data - Data + Note... -

Page 18: Ethernet

-25 to +70°C Relative humidity without condensation (acc. to RH2) 5 to 90% Vibrations according to 15 to 57 Hz, Amplitude 0.0375 mm, IEC 68-2-6 occasionally 0.075 mm 57 to 150 Hz, Acceleration 0.5 g occasionally 1.0 g OM 100.EPW400.202002.en... -

Page 19: Electromagnetic Compatibility In Line With Ec Directives

Technical data 3.1.9 Electromagnetic compatibility in line with EC directives Immunity according to EN 61000-6-2 / EN 61131-2 Electrostatic discharge (EN 61000-4-2) Contact min. 8 kV Clearance min. 15 kV Electromagnetic fields (EN 61000-4-3) 80 MHz – 1 GHz: 10 V/m 80% AM (1 kHz) 900 MHz ±5 MHz: 10 V/m 50% ED... -

Page 20: Sensor: Analog Standard Signals

In order to ensure repeating accuracy, a zero adjustment should be carried out before each work cycle or at regular time intervals (e.g. for ZKN model force transducers after approx. 10 minutes). OM 100.EPW400.202002.en... -

Page 21: Dms Signals

Technical data 3.1.13 DMS signals Force measuring (channel Y) via DMS force transducer. The input is selected in menu 'Configuration'. Nominal force or nomi- Adjustable in the menu nal distance: A/D converter: 16 bit = 65536 steps Nominal load of reso- 65536 steps, 1 step (bit) = nominal load / 65536 lution: Gain error:... -

Page 22: Overview Of Built-In Version

Attachment method 8 x threaded bolts M4 x 10 Protection class according to DIN IP 54 (front panel) 40050 / 7.80 IP 20 (housing) Films Polyester Resistance according to DIN 42115 Alcohols, diluted acids and alkalis, household cleaners OM 100.EPW400.202002.en... -

Page 23: Dimensions Of Installation Housing With Two Slots

Technical data 3.2.2 Dimensions of installation housing with two slots 3.2.3 Dimensions of installation housing with three slots OM 100.EPW 400.202002.en... -

Page 24: Hole Pattern Of Installation Housing (Rear View)

Technical data 3.2.4 Hole pattern of installation housing (rear view) Front view Installation aperture 175 x 150 mm OM 100.EPW400.202002.en... -

Page 25: Built-In Version: Digital Inputs I0 - I15 (37-Pin Connector)

Technical data 3.2.5 Built-in version: digital inputs I0 – I15 (37-pin connector) Designation Program bit 0 Program bit 1 Program bit 2 Program bit 3 Program bit 4 Program bit 5 Program strobe Offset external 0 V external Start measure- ment Reserve I 10... -

Page 26: Built-In Version: Digital Outputs Q0 - Q7 (37-Pin Connector)

/ NOK buzzer Ready for meas- urement Program ACK Switching point 3 / Item quantity warning + 24 V +24 V external + 24 V +24 V external Connection example of digital inputs and outputs Output function configurable OM 100.EPW400.202002.en... -

Page 27: Built-In Version: Pin Assignment, Dms Force Transducer (Channel Y)

Technical data 3.2.7 Built-in version: pin assignment, DMS force transducer (channel Y) Only hardware model EPW400.002.0X (with DMS subprint) 9-pin D-sub female connector DMS0 for DMS sensors DMS signal Measuring signal DMS + Measuring signal DMS - Reserve Reserve Reserve... -

Page 28: Built-In Version: Pin Assignment, Analog Signals

The connections are occupied the same as for the first card. Channel Y force transducer, analog Connection example of sensor with standard signal 0 - 10 V (ZKN with tare) 15-pin D-sub con- nector, analog I/O Output function configurable OM 100.EPW400.202002.en... - Page 29 Technical data Channel Y oil pressure sensor Connection example: ZDO 15-pin D-sub con- nector, analog I/O Channel X distance transducer Connection example of distance potentiometer (ZWW 10 V supply voltage) 15-pin D-sub connector, analog I/O Connection example of distance transducer (ZKW 24 V supply voltage) 15-pin D-sub con- nector, analog I/O OM 100.EPW 400.202002.en...

-

Page 30: Built-In Version: Pin Assignment, Analog Standard Signals

+10 V sensor supply Note Hardware model (2-channel) Version 22 is not provided with EPW 400.XX2.1X! Channel Y force transducer Connection example of sensor with standard signal 0 - 10 V (ZKN with tare) 15-pin D-sub con- nector, analog I/O OM 100.EPW400.202002.en... - Page 31 Technical data Channel Y oil pressure sensor Connection example: ZDO 15-pin D-sub con- nector, analog I/O Channel X distance transducer Connection example of distance potentiometer (ZWW 10 V supply voltage) 15-pin D-sub connector, analog I/O Connection example of distance transducer (ZKW 24 V supply voltage) 15-pin D-sub con- nector, analog I/O OM 100.EPW 400.202002.en...

-

Page 32: Overview Of Wall-Mounted Version

Supply voltage 24 V DC 2 Profibus interface (optional) Force transducer Y2 (only Version 3 RS232 interface (optional) Distance transducer X2 (only Ver- sion 22) 4 Distance transducer X1 Ethernet interface 5 Force transducer Y1 USB interface 6 Main switch OM 100.EPW400.202002.en... -

Page 33: Wall-Mounted Housing: Digital Inputs I0-I15 (25-Pin D-Sub Female Connector)

Technical data 3.3.3 Wall-mounted housing: digital inputs I0-I15 (25-pin D-sub female connector) Pin, D-SUB Color code Designation White Program bit 0 Brown Program bit 1 Green Program bit 2 YELLOW Program bit 3 White-blue Program bit 4 Brown-blue Program bit 5 Grey Program strobe White-yellow... -

Page 34: Standard Wall-Mounted Housing: Pin Assignment, Dms Force Transducer (Channel Y)

F+ DMS Sensor cable DMS+ Shield Shield 24 V DC Auxiliary power for external measuring sen- sor 24 V 0 V DC Earth external Signal + Input standardized measuring signal Signal - Measuring signal earth Tare Signal tare OM 100.EPW400.202002.en... - Page 35 Technical data When connecting the DMS using the 4-conductor technique, pins C and D and pins B and E are bridged. Wall-mounted housing: pin assignment, force transducer (channel Y) (12-pin round socket) Connection example: DMS without sensor cable Connection example of DMS with sensor cable Connection example of sensor with standard signal 0 - 10 V (ZKN with tare) 24 V supply voltage OM 100.EPW 400.202002.en...

- Page 36 Technical data Connection example: ZDO Pin assignment distance signal (channel X) The pin assignment is identical in hardware models EPW400.202.0X and EPW400.202.1X. Note For hardware model EPW 400.022.0X (2-channel) the second ana- log input card is installed for channel pair 2 X/Y! The connections are occupied the same as for the first card.

- Page 37 Technical data Connection example of distance transducer potentiometer (ZWW 10 V supply volt- age) Connection example: distance transducer (ZKW) OM 100.EPW 400.202002.en...

-

Page 38: Wall-Mounted Housing: Pin Assignment, Force Transducer (Channel Y) Only Hardware Model Epw 400.202.1X

Auxiliary power for external measuring sen- sor 24 V 0 V DC Earth external Signal + Input standardized measuring signal Signal - Measuring signal earth Tare Signal tare When measuring with internal measurement amplifier, pin E and pin L are bridged. OM 100.EPW400.202002.en... - Page 39 Technical data Connection example of sensor with standard signal 0 - 10 V (ZKN with tare) 24 V supply voltage Connection example: ZDO OM 100.EPW 400.202002.en...

-

Page 40: Interfaces

Capacitance per unit length < 30 pf/m 110 Ω/km Loop resistance ® Recommended cables For fixed installation of UNITRONIC BUS L2/FIP ® UNITRONIC BUS L2/FIP 7-wire ® For flexible installation of UNITRONIC BUS FD P L2/FIP Node addresses 3 to 124 OM 100.EPW400.202002.en... - Page 41 Technical data Profibus RXD/TXD-P CNTR-P (RTS) + 5 V RXD/TXD-N Note The output voltage from pin 6 for termination with a terminating re- sistor is + 5 V. OM 100.EPW 400.202002.en...

-

Page 42: Fieldbus Interface

Field bus bit NOK alarm Switching point S1 Switching point S2 Ready for measure- ment Program ACK Switching point S3 Output function options: Switching point S1 / Enable Switching point S2 / Buzzer Switching point S3 / Warning piece counter OM 100.EPW400.202002.en... - Page 43 Technical data Format of final values via fild bus (bytes 3 – 63): The end values are written on bytes 3 to 55 on the field bus (if this function is acti- vated). • Byte X (structure): Byte X Byte 3: Status (Status 2 = OK / Status 3 = NOK) Byte 4, 5, 6, 7: Running number...

- Page 44 The window extends from 8.00 mm to 11.60 mm => actual distance [mm] = 9.80 mm. The actual force [kN] is the point where the measurement curve intersects the actual distance [mm]. Force [kN] 8.00 mm 11.60 Actual force [mm] Distance Actual distance [mm] [mm] OM 100.EPW400.202002.en...

-

Page 45: Transport

Transport Transport Storage • Cover the electrical connections to protect them from dust, e.g. with adhesive tape. • Protect the display against sharp-edged objects. If necessary, attach a suitable protective cover (e.g. made of cardboard or hard foam). • Use a dry, ventilated room for storage. •... -

Page 46: Operating The Device

EPW 400. Depending on operating mode, the buttons and fields are assigned to different displays and functions. The windows are explained in the corresponding chapters of the operating manual. The meaning of each button is defined in the description of the different menus. OM 100.EPW400.202002.en... -

Page 47: Main Menu 'Measuring

Operating the device Main menu 'Measuring' During measuring operation, the measuring display appears. The measurement curve, the configured windows and the envelopes are displayed in graph form. The selected zoom area displays the plotted force/travel area. In the upper status bar, the current process number is faded in. The second line dis- plays the Wnumber assigned to the process and the EPW 400 process name. -

Page 48: Icons

Connection via Ethernet to a PC not yet possi- not initialized ble. Ethernet interface ini- Connection via Ethernet to a PC realized tialized No USB stick in- No USB stick found serted USB stick inserted USB stick detected OM 100.EPW400.202002.en... -

Page 49: Full Screen Display

Operating the device 5.3.3 Full screen display: A change between normal display and full screen display is possible by tapping on the diagram. As soon as a measurement is started, a change to full screen mode takes place automatically. OM 100.EPW 400.202002.en... -

Page 50: Menu 'Zoom

Goes back to the previous zoom view; this but- ton appears when a change is made to the zoom setting. The zoom area can be changed by direct input of the required value. Tap the input field you wish to change. OM 100.EPW400.202002.en... - Page 51 Operating the device A window with a numerical tap field will be displayed: Enter the required value and confirm it with the 'Enter' button. It is also possible to change the zoom area graphically by first tapping the diagram to bring up a crosshair.

- Page 52 As soon as a purple frame becomes visible, the <Zoom in frame> button appears for zooming in the selected frame; When a change is made to the zoom setting, an 'Undo' button appears, which will take you back to the previous zoom view. OM 100.EPW400.202002.en...

-

Page 53: Menu 'Gauge Curve

Operating the device Menu 'Gauge curve' By tapping on the gauge curve, the associated pair of values is shown. 5.5.1 Buttons Back, goes back to main menu "Measuring mode" OM 100.EPW 400.202002.en... -

Page 54: Menu 'Windows

A window is selected by tapping on 'Text field selected window' followed by the input of the window number or by tapping the window to be selected in the diagram. Four text fields show the dimensions of the selected window. OM 100.EPW400.202002.en... -

Page 55: Edit Window Type

Operating the device 5.6.1 Edit window type By tapping on button 'Edit window type', it is possible to edit the type of the selected window. Online window Window '0' Three window types are available for online window Window '0' which cannot be changed: •... - Page 56 The selected window remains in the absolute position Max. X The selected window is positioned with reference to the maximum value reached (max. X) Mean value The selected window is positioned with reference to the last speci- fied OK curves stored (mean value X) OM 100.EPW400.202002.en...

- Page 57 Operating the device Window 'Max. X' The selected window is positioned with reference to the maximum value reached (max. X). The position can be defined using the 'Absolute distance lower limit' and 'Absolute distance upper limit' values. Proceed as follows: ...

- Page 58 'right-hand side highlighted', 'top highlighted', 'bottom highlight- ed' and 'entire window highlighted'. The corresponding side can also be highlighted by tapping the line of the window. The whole window is high- lighted by tapping in the centre of the window. OM 100.EPW400.202002.en...

- Page 59 Operating the device The 'Dustbin' button deletes the selected window. You can change the size of a window − By entering the required values in the text fields or − By marking one side and tapping on the 'arrow buttons' Arrow buttons Move the highlighted side Move the highlighted side...

- Page 60 It is also possible to move the window (with the whole window highlighted) using the arrow keys , , and . 'Accept window' button Close this window by tapping on the "Accept window" button. The current window settings will be adopted. OM 100.EPW400.202002.en...

-

Page 61: Menu 'Envelope Curve

Operating the device Menu 'Envelope curve' In this menu the envelope parameters can be changed. The settings in this menu apply to the process currently selected (e.g. process 3). Copy envelope Copies the lower entered envelope curve pa- curve parameters rameters to the upper ones or the upper ones to the lower ones. - Page 62 A change from mode 'Evaluation' to mode 'Teach' is always possible for teaching fur- ther curves. If in mode 'Evaluation' a curve violates the upper or the lower envelope, a button ap- pears in menu 'Envelope' where a teach-in of this curve can be added to the envelope. OM 100.EPW400.202002.en...

-

Page 63: Text Fields

Operating the device 5.7.1 Text fields Force value by which the selected envelope (upper or lower) is moved vertically in relation to the corresponding envelope curve. End Y: Upper limit of the envelope. Begin Y: Lower limit of the envelope. Upper / lower: Choice of whether the parameter applies to the upper or lower envelope. - Page 64 X / End X and limited or expanded vertically using Begin Y / End Y. Go to 'Evaluate' mode. Go to the 'Main menu'. The curves will now be recorded, and evaluated on the basis of the envelope and any windows that have been set. OM 100.EPW400.202002.en...

-

Page 65: Configuring The Epw 400

Configuring the EPW 400 Configuring the EPW 400 Tapping the 'Menu' button opens the Configuration menu. Here you can call up the submenus, which enable you to adjust the settings for the following areas: Processes − Select process number (e.g. 5) −... -

Page 66: Select Process Number (64 Processes)

You can also enter a number containing up to ten digits for each process (T num- ber). Tap on the number and a window will open with a numerical keypad, which can be used to enter the number. OM 100.EPW400.202002.en... -

Page 67: Copy Processes

Configuring the EPW 400 6.1.3 Copy processes Tapping on 'Copy Process' opens a window in which you can set the parameters of the current process to be copied to other processes: By tapping the input fields behind 'from process' and 'to process', the input window with the numerical keypad will be opened for the direct input of the numbers of the processes. -

Page 68: Settings

By tapping the input field in front of 'Password level to switch processes', the input window with the numerical keypad will be opened. Here the authorization level can be set that is necessary for the process changeover (authorization level 3 only). OM 100.EPW400.202002.en... -

Page 69: Saving / Restoring Parameters

Configuring the EPW 400 6.1.5 Saving / restoring parameters Actuating button 'Save / restore parameters', opens the submenu for copying all parameters and processes from the USB stick. Copy parameters to USB stick Tapping on the 'Save Parameters on USB Stick' copies all parameters and processes to the USB stick. -

Page 70: Configuration

Configuring the EPW 400 Configuration − Configuration of process-dependent parameters: force sensor, dis- tance sensor, measuring parameters (measured data acquisition, start/stop conditions) and switching points. − Configuration of global parameters (valid for all processes): I/O configuration and valuation options. OM 100.EPW400.202002.en... -

Page 71: Force Sensor, Channel Y

Configuring the EPW 400 6.2.1 Force sensor, channel Y In the opened window it is possible to fix the parameters of the force sensor separately for each process. The setting of the current process can be copied to other processes. EPW 400.X02.X EPW 400.X02.0: DMS hardware version 6.2.2... -

Page 72: Nominal Force Of The Force Sensor (Nominal Load)

An offset adjustment is always necessary after changing or adding a force transducer. Make sure the force transducer is not loaded during the adjustment. Note Generally, an offset adjustment should be carried out at least once a day or after about 1000 measurements OM 100.EPW400.202002.en... -

Page 73: Offset Limit Force Sensor

Offset limit force sensor The offset limit is used set the maximum tolerated offset to 10%, 20% or 100% of the nominal force. Offset adjustment for sensor with normal signal output: − TOX ® standard sensor: 10% (20% possible for compensation) ... -

Page 74: Force Sensor Calibration

Enter the value of the measuring value to be displayed for the electric measuring signal and confirm this value with the 'Enter' button. It is also possible to enter the electric measuring signal numerically by tapping on the input field. OM 100.EPW400.202002.en... -

Page 75: Force 2

Configuring the EPW 400 6.2.13 Force 2 To teach, click on button 'Teach'. Read in the current electric measuring signal. Tap on the 'Force 2' input field. A window with a numerical tap field will be displayed: Enter the value of the measuring value to be displayed for the electric measuring signal and confirm this value with the 'Enter' button. -

Page 76: Distance Sensor

In the opened window it is possible to select the parameters of the distance sensor separately for each channel pair (measuring board). The setting of the current process can be copied to other processes. No resistance potentiometer Resistance potentiometer OM 100.EPW400.202002.en... -

Page 77: Nominal Distance Of The Distance Sensor (Nominal Load)

Configuring the EPW 400 6.2.16 Nominal distance of the distance sensor (nominal load) In this line you can set the nominal distance for the distance transducer used. The nominal distance is specified in mm. The nominal distance is achieved at the maxi- mum measuring signal (10 V) of the distance transducer. -

Page 78: Offset Limit Of Distance Sensor

Tap on the input field next to 'Forced offset' to switch the forced offset on or off. The last setting displayed will be adopted. 6.2.21 Filter With the parameter 'Filter' the cutoff frequency of the measuring channel can be set. Value range: 5 Hz - 1000 Hz OM 100.EPW400.202002.en... -

Page 79: Distance Sensor Calibration

Configuring the EPW 400 6.2.22 Distance sensor calibration Calibration: This function is used to specify the allocation of the electric measuring signal and of the measuring variable to be displayed. This is a pure two- point calibration. • Distance 1: To teach, click on button 'Teach'. - Page 80 'Enter' button. It is also possible to enter the electric measuring signal numerically by tapping on the input field. Accept calibration Close the window 'Enter nominal force' by tapping on button 'Accept calibration'. The configuration will be adopted. OM 100.EPW400.202002.en...

-

Page 81: Measuring Parameters

Configuring the EPW 400 6.2.23 Measuring parameters By actuating button 'Measuring parameters' a window is opened branching into the menus 'Meas. Parameters' and 'Start/Stop condition': 6.2.24 Measured data acquisition (measuring parameters) The mode for measuring data acquisition is always set for the process currently acti- vated only. -

Page 82: Distance Rising

Tapping on the value after the text "X interval" opens the input window with the nu- merical keypad. Here you can determine the accuracy of measurement up to 1/100 OM 100.EPW400.202002.en... -

Page 83: Insert Max. Force At The End Of The Curve

Configuring the EPW 400 6.2.29 Insert max. force at the end of the curve Independent of the acquisition of measured data, the max. force at the end of the curve can be displayed. This function can be switched on or off (practical for 'distance increasing' or 'distance increasing or decreasing'). -

Page 84: Force-Triggered

The field 'abs.' indicates whether or not a triggered measurement is based on the absolute zero point. The 'analog out' field is only displayed if the analog outputs are configured in the Configuration I/O menu. Close the 'switching points' window by tapping on the 'Accept' button. The configuration will be adopted. OM 100.EPW400.202002.en... -

Page 85: Configuration I/O

Configuring the EPW 400 Note: Firmware version EPW 400 Up to EPW 400 version V1.06 the outputs of switching points SP1- SP3 are only updated while measurement is in progress. From EPW 400 version V1.07 onwards, the outputs of switching points SP1-SP3 are constantly updated. - Page 86 By tapping on the input fields, a shift to the corresponding function takes place. In this window, the analog outputs are configured. Close the window 'Configuration I/O' by tapping on the button 'Accept'. The configuration will be adopted. OM 100.EPW400.202002.en...

-

Page 87: Configuring The Analog Outputs

Configuring the EPW 400 6.2.36 Configuring the analog outputs Depending on requirements, the relationship between outputs 0 and 1 can be defined here. Selection Function Actual distance Outputs the actual value of the distance Output 0: value [V] sensor Actual force value Outputs the actual value of the force sen- Tare signal Outputs a tare signal... -

Page 88: Valuation Options

Monitor TDC sensor The TDC sensor (TDC position) must be exited when measuring is started, otherwise an error message will be emitted. Close the window 'valuation parameters' by tapping on the button 'Ac- cept'. The configuration will be adopted. OM 100.EPW400.202002.en... -

Page 89: Apply Configuration

Configuring the EPW 400 6.2.42 Apply configuration After each change you will be asked when leaving the menu whether the change shall be stored for the current process only, be copied to all the 64 processes, or be copied to several consecutive processes: ... -

Page 90: Data

You can scroll up or down using the "" and "" arrow keys. The number of measured values in the last measurement is displayed in the top right-hand corner. The number of measured values should ideally be approximately 250. OM 100.EPW400.202002.en... -

Page 91: Final Values

USB stick. The name of the EPW 400 device as well as date and time will be used as name of the data file. The data can be found on the USB stick in the "Tox\Archive" folder. Close the 'Curve data' menu by tapping on 'Exit'. -

Page 92: Settings

USB stick. The name of the EPW 400 device as well as date and time will be used as name of the data file. The data can be found on the USB stick in the "Tox\Archive" folder. 6.3.3... -

Page 93: Settings For Data Export To Pc

Settings for data export to PC Here you can adjust the settings for exporting data to a PC. After the export, the data ® are available as a '.csv-file' in the corresponding directories (to be set in TOX soft- Ware). -

Page 94: Lot Size

(no message or no switching-off of the machine). If the tick is set in 'Main menu', the value will be displayed in the second line of the main menu. Only one counter can be displayed in the main menu. OM 100.EPW400.202002.en... -

Page 95: Shift Counter

Configuring the EPW 400 Close the 'Job counter' window by tapping on the 'Accept' button. The displayed values will be adopted. 6.4.2 Shift counter To open this menu, tap on the 'Shift counter' button: In the text fields of the first two lines of this menu all OK parts as well as the total number of parts produced in a shift are displayed. -

Page 96: Tool Counter

If the tick is set in 'Main menu', the value will be displayed in the second line of the main menu. Only one counter can be displayed in the main menu. Close the window 'Tool counter' by tapping on button 'Accept'. The dis- played values will be adopted. OM 100.EPW400.202002.en... -

Page 97: Diagram Settings

Configuring the EPW 400 Diagram settings In this window the settings for the display of the diagrams are made. The number of last curves that can be displayed on the touch screen is increased or decreased using the und arrows. The corresponding function is activated (X) or deactivated by tapping on the checkbox (up to the last nine curves can be displayed): •... -

Page 98: Supplemnt

Manage authorization levels / password Language Change the language version Communication parame- PC interface, field bus parameters ters In-/Outputs Current status of digital inputs/outputs Date/Time Display of current time and date Device name Enter a designation for the EPW 400 OM 100.EPW400.202002.en... -

Page 99: User Administration

Configuring the EPW 400 6.6.1 User administration 6.6.1.1 Access administration via user log-on The rights of the EPW 400 are managed in four authorization levels. After each start, the program will be on authorization level 0. For changing the access level, tap on button 'User administration': Authorization level 0 Machine operator: permission only for functions related to starting process monitoring... - Page 100 Configuring the EPW 400 Default setting: Authorization level 1: TOX Authorization level 2: TOX2 Authorization level 3: TOX3 Note: the system is case-sensitive! Confirm the password with the 'Enter' button. Log off when inactive Log off takes place automatically after 10 minutes of inactivity.

- Page 101 Configuring the EPW 400 6.6.1.2 Access administration via digital inputs The access level can also be pre-selected via the digital inputs. For this purpose, Input 13 must be set to 'Authorization Bit 0' (see chapter Configura- tion I/O, p. 85) The access level is then pre-selected with inputs 13 and 14.

-

Page 102: Language

In this menu, the settings for the PC interface (field bus, Ethernet) are made For the version with Profibus an integrated Profibus module is used, for other field buses an Anybus-S module from HMS is used which is available for almost all com- mon field buses. OM 100.EPW400.202002.en... -

Page 103: Ip Address

2). Close this window by tapping on the 'Accept' button. The displayed pa- rameters will be adopted. 6.6.5 Remote access ® Remote maintenance can be activated after consultation with TOX PRESSOTECHNIK (requires authorization level 2). OM 100.EPW 400.202002.en... -

Page 104: In-/Outputs

In this window, the actual state of the digital inputs/outputs and of the analog input is monitored. When tapping in menu 'Supplement' on ’in- puts/outputs' you reach this selection window: Tap on the corresponding button for calling up the required submenu. OM 100.EPW400.202002.en... -

Page 105: Internal Digital I/O

Configuring the EPW 400 6.6.7 Internal digital I/O An activated input/output is marked by a green rectangle, a deselected input/output is marked by a red rectangle. The function of the occupied inputs and outputs is de- scribed in clear text. Inputs: The status of the digital inputs on the EPW 400 is displayed. -

Page 106: Field Bus Parameters

When tapping on the input field between the arrows, you can change the number of the Profibus address with the help of the numerical keypad. Note: After changing the Profibus address, a new start of the device is re- quired! OM 100.EPW400.202002.en... -

Page 107: Read Inputs To Anybus-S Module

Configuring the EPW 400 6.6.10 Read inputs to Anybus-S module Activation of the device via field bus Activation of the device via digital inputs/outputs. For changeover, tap on the input field next to 'read inputs from anybus module'. 6.6.11 Log final values on field bus The final values will be output to the field bus interface ... -

Page 108: Profibus / Anybus

By tapping on the button of the corresponding output, the output is activated or deactivated. The color of the rectangle will correspondingly change. Changes are applied without further confirmation. The changes remain effective until the 'Inputs/outputs' submenu is exited. To close the window, tap the 'Exit' button. OM 100.EPW400.202002.en... -

Page 109: Analog Inputs

Configuring the EPW 400 6.6.16 Analog inputs In this window the analog measured values are displayed. Version 22: The corresponding value is displayed here depending on which measuring board is selected or set. To close the window, tap the 'Exit' button. OM 100.EPW 400.202002.en... -

Page 110: Date/Time

The numerical keypad field appears on the display. Tap on the field for the value that needs to be changed (date: dd.mm.yyyy, time: hh:mm:ss). Close this window by tapping on the 'Accept' button. The current time and date are adopted. OM 100.EPW400.202002.en... -

Page 111: Device Name

Configuring the EPW 400 6.6.18 Device name Here a name for the EPW 400 can be allocated. If several EPW 400 devices are used, it is reasonable to give each EPW 400 device a different name. If, for example, you wish to store data on a USB stick, the assigned name is used as file name, so that the saved data can be allocated to a certain EPW 400 device. -

Page 112: Plc Interface Pulse Diagrams

Up to EPW 400 firmware version V1.06, the outputs of switching points SP1-SP3 are only updated while measurement is in progress. From firmware version V1.07 onwards, the outputs of switching points SP1-SP3 are constantly updated. OM 100.EPW400.202002.en... -

Page 113: Changing The Program Number

PLC interface pulse diagrams 7.1.1 Changing the program number Program bit 0-5 Program strobe Program ACK Delay time Strobe / Ack: min 10 ms, max. 20 ms New program number applied and data read, max. 100 ms History Program 7.1.2 Zero point adjustment Program bit 0 Channel X = 0 / Channel Y = 1... -

Page 114: Software Module Tox Software

• Processing and filing of device configurations • Offline - setup of device configurations ® Please observe the comprehensive separate operating manuals for TOX Ware soft WORX and the EPW 400 software module. Networking via Ethernet Transfer of measuring data to the PC – Ethernet The PC used for data acquisition can communicate with several EPW 400 devices via the Ethernet interface. -

Page 115: Error Messages

Error messages Error messages Error number Error message No error Started, not ready to measure Online window violated OK job counter limit reached Total job counter limit reached OK shift counter limit reached Total shift counter limit reached Tool counter limit reached Error transmit online window piece part NOK TDC sensor not left... -

Page 116: Firmware Update

10.1 Update from version V1.08 To import new firmware you will need a USB stick. On this USB stick create a folder 'TOX' directly in the root directory: Example: LW 'USB_128k (D:) Tox ® Unzip the files you have received from TOX PRESSOTECHNIK into the 'TOX' folder. - Page 117 Firmware update Click on button 'Yes' to install the update. After the update, the following message will appear: OM 100.EPW 400.202002.en...

-

Page 118: Decommissioning

Dispose of the old pressing monitor at the nearest electronic dis- ® posal site or contact TOX PRESSOTECHNIK. The labels on the product, accessories and in the associated documentation specify that the product and accessories (e.g. power supply units, USB cables) must not be disposed of in the normal household waste at the end of their service life.

Need help?

Do you have a question about the EPW400 and is the answer not in the manual?

Questions and answers